The Evolution of EDM Wire

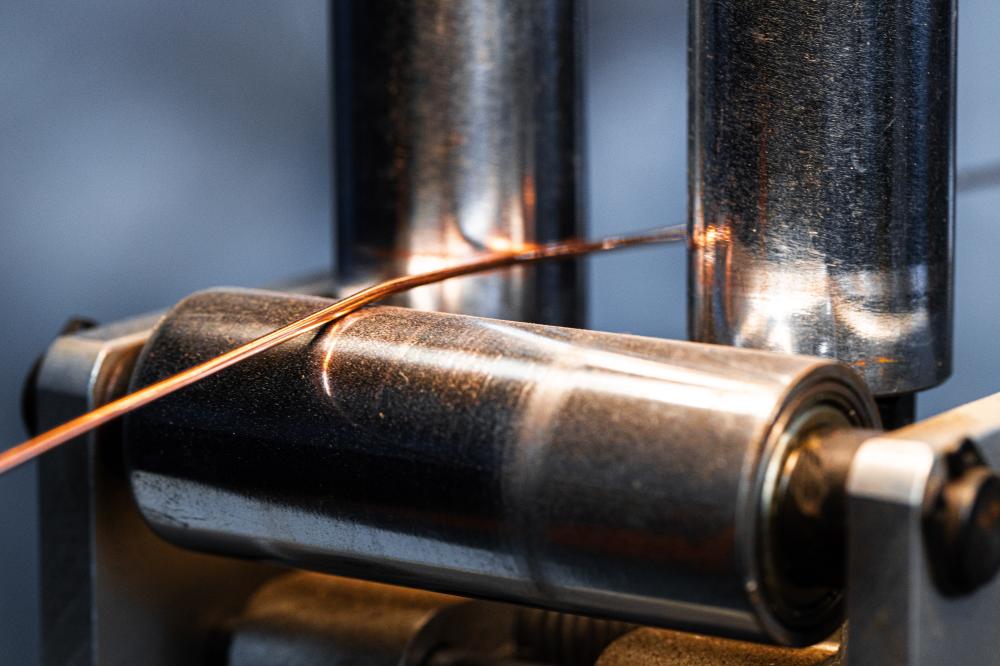

The journey of EDM wire has been fascinating, evolving from simple copper wires to the highly engineered wires we know today. Originally, EDM wire technology was synonymous with copper, a choice that was largely driven by its conductivity and ease of use. However, as the demand for more precision and efficiency in machining grew, so did innovations in wire composition.

Manufacturers began experimenting with brass, a copper-zinc alloy, which provided better performance characteristics for certain applications. Today, the cutting-edge Plasma™ coated EDM wire is recognized for its superior performance, thanks to advanced proprietary coatings that improve its flushing ability. These innovations have enabled unprecedented increases in metal removal rates, setting new standards for efficiency and precision in the industry.

Applications in Modern Industries

EDM wire has become indispensable across a range of industries, from aerospace to medical equipment manufacturing. In aerospace, the precision of EDM allows for the creation of complex components that meet stringent safety and performance standards. This precision is critical for modern aircraft, where even minute discrepancies can have significant ramifications.

In the medical field, where delicate and precise tooling is required, EDM wire offers the high precision needed to produce small, intricate parts for medical devices. As someone who has worked with various EDM wires, I can attest to the reliability and accuracy they provide in creating components that adhere to strict medical standards. The consistency of results with EDM wire is a common expectation that both seasoned professionals and newcomers in the industry appreciate.

Advantages of Using EDM Wire

One of the major advantages of using EDM wire is its ability to cut materials that are difficult to machine by conventional methods, such as hard metals or those with complex geometries. The non-contact nature of EDM minimizes the risk of damaging delicate workpieces, ensuring a clean, accurate cut every time. This is particularly advantageous in prototyping scenarios, where precision and adaptability are key.

With years of professional experience machining precision parts, Anco Precision Inc. offers top-grade CNC machining services that leverage the capabilities of advanced EDM wire technology. This ensures our clients receive parts that not only meet but often exceed expectations in accuracy and finish. We understand the pressure on companies to deliver high-quality results under tight deadlines, and the right EDM wire choice plays a crucial part in achieving these goals without compromising quality.

Another benefit is the ability to automate processes, which in turn reduces labor costs and increase production speeds. This is essential for industries seeking to maintain competitiveness by optimizing their manufacturing processes. EDM wire technology, with its efficiency and reliability, is at the forefront of this industrial evolution, offering solutions that save time while maintaining high quality.

Selecting the Right EDM Wire

Choosing the right EDM wire depends on several factors, including the material being cut, required precision, and specific project requirements. Each wire type, from standard brass to Plasma™ coated wire, offers unique advantages tailored to different applications. For example, projects requiring high tensile strength and heat resistance might benefit from molybdenum wire, while those focusing on cost-effectiveness might prefer traditional brass wire.

At Anco Precision, we guide our clients in selecting the optimal EDM wire for their specific needs, drawing from our extensive industry experience and dedication to quality. Whether it’s a bespoke project or part of a larger production run, we ensure the selection process aligns with performance requirements and budget constraints.

Our commitment to customer satisfaction is reflected in our comprehensive service offerings, which include expert advice and efficient production processes. Clients can expect not only precision-machined parts but also a collaborative experience that tailors our resources to their unique project demands.

Customers, ranging from inventors to large corporations, rely on Anco Precision’s detailed consultations and immediate quotes to kickstart their projects seamlessly. Our approach ensures that every project, no matter how complex, receives the utmost care and precision, leveraging the best in EDM wire technology to deliver outstanding results.

Unraveling the Wire EDM Process

The Wire EDM process is a fascinating blend of precision and technology, pivotal to many industries. It’s a method of cutting conductive materials with an electrically charged wire, effectively slicing through with sparks. This is invaluable for intricate shapes and complex geometries that traditional machining struggles with.

At Anco Precision Inc., the Wire EDM capabilities are harnessed to produce components with exact precision. In industries like aerospace and medical, where accuracy is not just desired but vital, Wire EDM offers a solution that ensures components are manufactured to exact specifications. The process involves submerging the material in a dielectric fluid and guiding the wire accurately with CNC controls, allowing for cuts that are minute and precise.

Having been part of this field for over four decades, we’ve seen the evolution of Wire EDM technology. Each advancement integrates more accuracy and efficiency, traits that reflect heavily in our products. The versatility of Wire EDM shines through in our ability to cater to different sectors, including automotive and marine industries.

Precision and Versatility: A Deeper Dive

Wire EDM is not just about cutting; it’s about delivering perfection through precision. The machinery and expertise at Anco Precision ensure that even the most complex designs are achievable. This method excels in producing small, intricate parts without compromising on quality.

Our team of expert machinists continually hones their skills, ensuring that they are competent in using the latest Wire EDM equipment. Through continuous training, we keep pace with technological advancements, enabling us to provide cutting-edge solutions to a variety of machining challenges.

In terms of versatility, Wire EDM is second to none. Its application ranges from crafting tiny gears for medical devices to robust engine parts for the automotive industry. This capability is crucial for our diverse clientele who require rapid prototyping and high-quality production runs.

In my experience, a successful Wire EDM operation at Anco Precision often involves a synergy between machine precision and human expertise. Our machinists’ ability to interpret complex designs and execute them flawlessly with Wire EDM is what sets us apart from competitors.

Real World Applications and Innovations

The real power of Wire EDM lies in its applications across various fields. In the aerospace sector, where Anco Precision frequently operates, the process is used for components that withstand extreme conditions. This ensures safety and reliability, both of which are non-negotiable in aviation.

Similarly, in the medical field, Wire EDM is critical for producing tools and devices that require utmost preciseness. Anco Precision has repeatedly delivered components that adhere to strict medical standards, showcasing Wire EDM’s potential to make a difference in critical healthcare outcomes.

An anecdote that resonates with me is when a client approached us needing a prototype for a novel device. Utilizing Wire EDM, we created a functional prototype faster than the conventional methods, bringing their innovation closer to reality much sooner than anticipated.

Such stories are testament to the transformative power of Wire EDM. At Anco Precision, we are proud of the role we play in turning complex ideas into tangible solutions, demonstrating not only our capabilities but the revolutionary nature of Wire EDM itself.

The Precision and Evolution of Wire EDM

Wire EDM Services have become an essential process in modern manufacturing, offering a unique capability to cut intricate shapes in conductive materials without physical contact. This precision technique stands out particularly in industries like aerospace and medical, where maintaining strict tolerances is crucial. As a family-owned CNC machine shop with over four decades of experience, Anco Precision Inc. has mastered this art, ensuring that each project meets the highest standards of quality and accuracy.

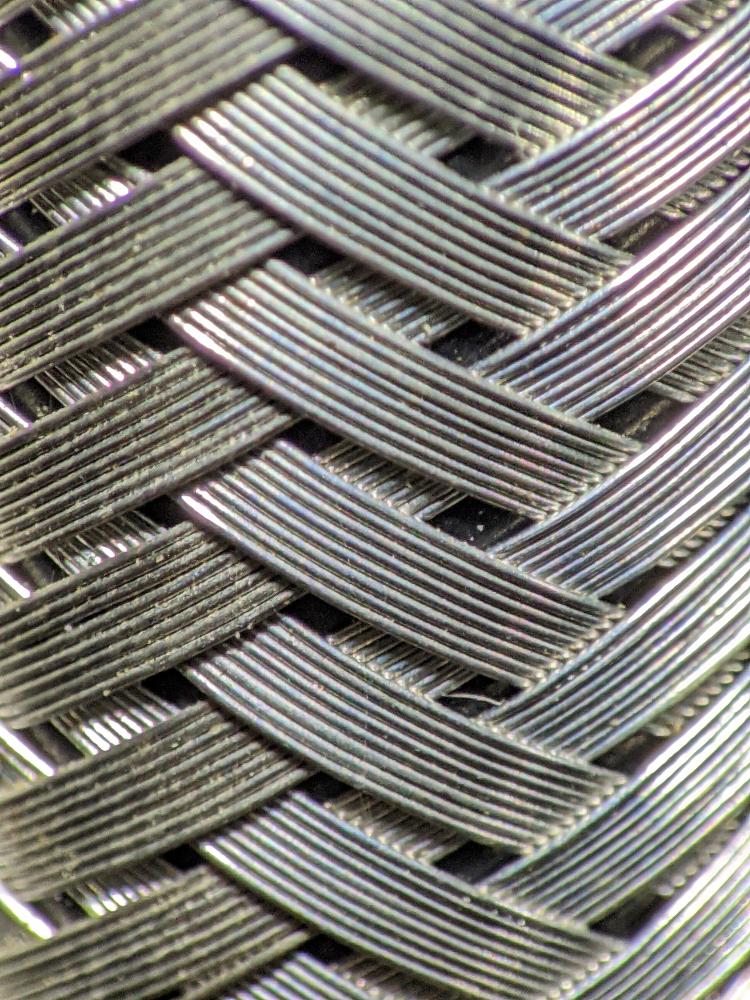

Unlike conventional machining methods, Wire EDM utilizes a thin, electrically charged wire to erode material with controlled sparks, creating burr-free edges on complex geometries. This method is ideal for applications requiring tight internal corners and cut features on hardened or exotic materials, such as titanium and Inconel. Anco Precision’s longstanding commitment to precision has positioned them at the forefront of delivering exceptional Wire EDM Services to a broad range of industries.

Applications and Expertise in Wire EDM Services

One of the standout features of Wire EDM Services is their ability to create complex components for specialized industries. From aerospace components to medical instruments, Anco Precision understands the demanding needs of these sectors. Their expertise allows them to cater to diverse requirements, manufacturing anything from surgical tools to precision turbine slots. Each project benefits from Anco’s dedication to exacting standards, ensuring parts are delivered with the utmost precision.

In the automotive industry, Wire EDM is used to produce precision powertrain tools and prototype components with exacting standards. Anco Precision excels in this area, offering services that include the production of custom car parts and intricate mold inserts. Their team of highly trained machinists utilizes state-of-the-art equipment to provide consistent, high-quality results, which has earned them a reputation for reliability and excellence in Wire EDM Services.

In the medical field, the need for precision and biocompatibility makes Wire EDM indispensable. Anco Precision leverages their extensive experience to manufacture medical instruments and implants with meticulous attention to detail. The process ensures that all parts are burr-free and meet the strict standards required in medical applications, thereby enhancing the safety and efficacy of medical devices.

Personal Insights and Exceptional Service

Commitment to Quality

Having been at the helm of technological advancements for over 40 years, our team at Anco Precision brings both seasoned expertise and innovative solutions to Wire EDM Services. Our commitment to quality is not just a standard–it’s a tradition. This ensures that whether you’re a small inventor or a large corporation, we provide the same exceptional care and precision in every cut.

Why Choose Anco Precision

Clients often share stories of how our Wire EDM Services have transformed their projects. One long-time customer remarked on how our quick turnaround times and unparalleled precision helped their product launch exceed expectations. These testimonials highlight our dedication to meeting client needs with the utmost professionalism and care.

- Dedicated team with extensive training.

- State-of-the-art equipment.

- Over 40 years of industry experience.

- Competitive pricing and rapid delivery.

Engaging with Anco Precision means more than just obtaining a service; it means partnering with a team that takes pride in every facet of Wire EDM Services, from the initial concept to the final product. We invite you to connect with us to discuss how we can contribute to your project’s success through precision machining.

What is EDM Wire and how does it work?

EDM (Electrical Discharge Machining) wire is a specialized tool used in a machining process that relies on electrical discharges to shape conductive materials. The process involves a thin, electrically charged wire that erodes material with high-frequency sparks, allowing for precision cutting without making physical contact with the material. This method is invaluable for creating intricate shapes and is particularly useful in industries like aerospace and medical where exacting standards are crucial. I often explain it as the sculptor’s chisel in the world of engineering–transforming complex designs into precision parts. Are you curious about how this compares to traditional machining methods? Feel free to ask!

Are there any common misconceptions about EDM Wire?

One common misconception is that EDM wire is limited to specific materials or applications. In reality, this technology is incredibly versatile and can handle a wide range of materials, including hard metals like titanium and Inconel, which are often challenging for traditional machining methods. Another misconception is that EDM is slower or less efficient, but with advancements like Plasma™ coated wires, we see improved speeds and efficiency that rival and sometimes surpass conventional methods. It’s fascinating to see how misconceptions fade when people witness the capabilities of EDM firsthand during a tour of our shop. What assumptions did you have before learning about EDM?

How do you choose the right EDM Wire for a project?

Selecting the appropriate EDM wire depends on several factors such as the material being cut, required precision, and specific project needs. For instance, brass wire works well for general purposes due to its balance of cost and performance. However, if a project demands high tensile strength, molybdenum wire might be more suitable. We’ve been helping clients navigate these choices for years, ensuring they meet both performance needs and budget constraints. Does your project involve unique materials or require specific tolerances? Discussing these details can help refine the wire selection further.

What are some advancements in EDM Wire technology?

Recent advancements in EDM wire technology have primarily focused on wire coatings and material composition enhancements. Plasma™ coated wires, for example, offer improved flushing and increased cutting speeds due to their advanced proprietary coatings. This translates to higher efficiency and precision, vital for industries with exacting standards like aerospace and medical. Having witnessed these innovations in action, it’s impressive to see how much they improve the overall performance of machining projects. What innovations in your field have changed your approach to problem-solving?

What are the benefits of using EDM Wire in machining projects?

EDM wire offers several benefits, particularly its ability to cut complex geographies and hard-to-machine materials without physical contact. This results in minimal risk of damaging delicate workpieces and ensures precise cuts. Additionally, the process can be fully automated, helping reduce labor costs and increase production speed. For instance, when we manufacture small, intricate parts for medical devices, EDM wire ensures the highest precision and quality. How important is precision in your industry, and how do you achieve it?

How can EDM Wire benefit the prototyping process?

In prototyping, where precision and adaptability are key, EDM wire is incredibly advantageous. It allows for rapid iteration of design prototypes without the need for altering physical tooling every time there’s a design change. This saves both time and resources, enabling quicker development cycles. I’ve worked with numerous clients who were able to bring their innovations to life much faster thanks to EDM’s capabilities. Have you considered how speeding up your prototyping process could impact your time-to-market?

What expertise does Anco Precision bring to Wire EDM Services?

At Anco Precision, we pride ourselves on over 40 years of experience in providing top-notch Wire EDM services. Our team undergoes extensive training to stay abreast of the latest in EDM technology, ensuring each project meets the highest standards of quality. From aerospace to medical industries, we’ve delivered exceptional results thanks to our state-of-the-art equipment and dedicated team. It’s rewarding to see how our precision and speed make a tangible difference in our clients’ projects. Are you looking for reliable machining partners who understand your industry’s demands?

Why is Wire EDM so important in modern industries?

Wire EDM plays a crucial role in modern industries due to its capability to produce highly accurate components essential for safety-critical sectors like aerospace and medical. The technique’s precision ensures parts meet stringent tolerances required for complex applications. For example, in the aerospace industry, Wire EDM is trusted for producing components that endure extreme conditions while maintaining safety. Our experience shows that having the right tools and expertise is not just about meeting expectations but also about defining industry standards. How do you ensure quality and precision in your work?