Exploring Wire EDM Technology

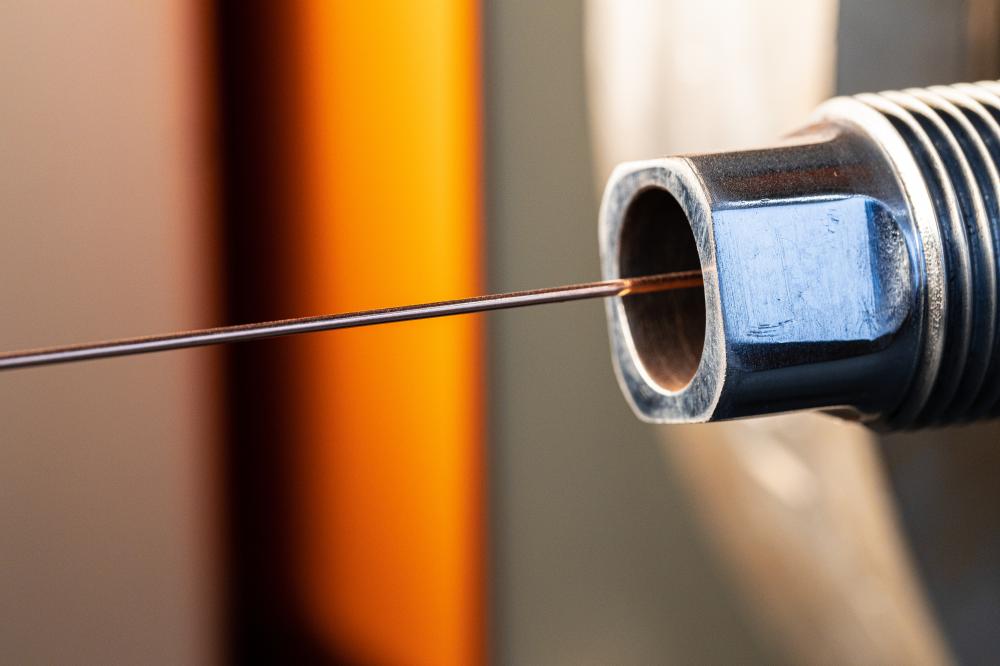

At Anco Precision Inc., we have witnessed firsthand the transformative power of Wire EDM in the machining industry. Wire EDM, short for Electrical Discharge Machining, is a precision-oriented process that utilizes a thin, single-strand metal wire to cut through metal. This technique is invaluable in scenarios where traditional methods falter, particularly with materials such as titanium, aluminum, and hardened steel.

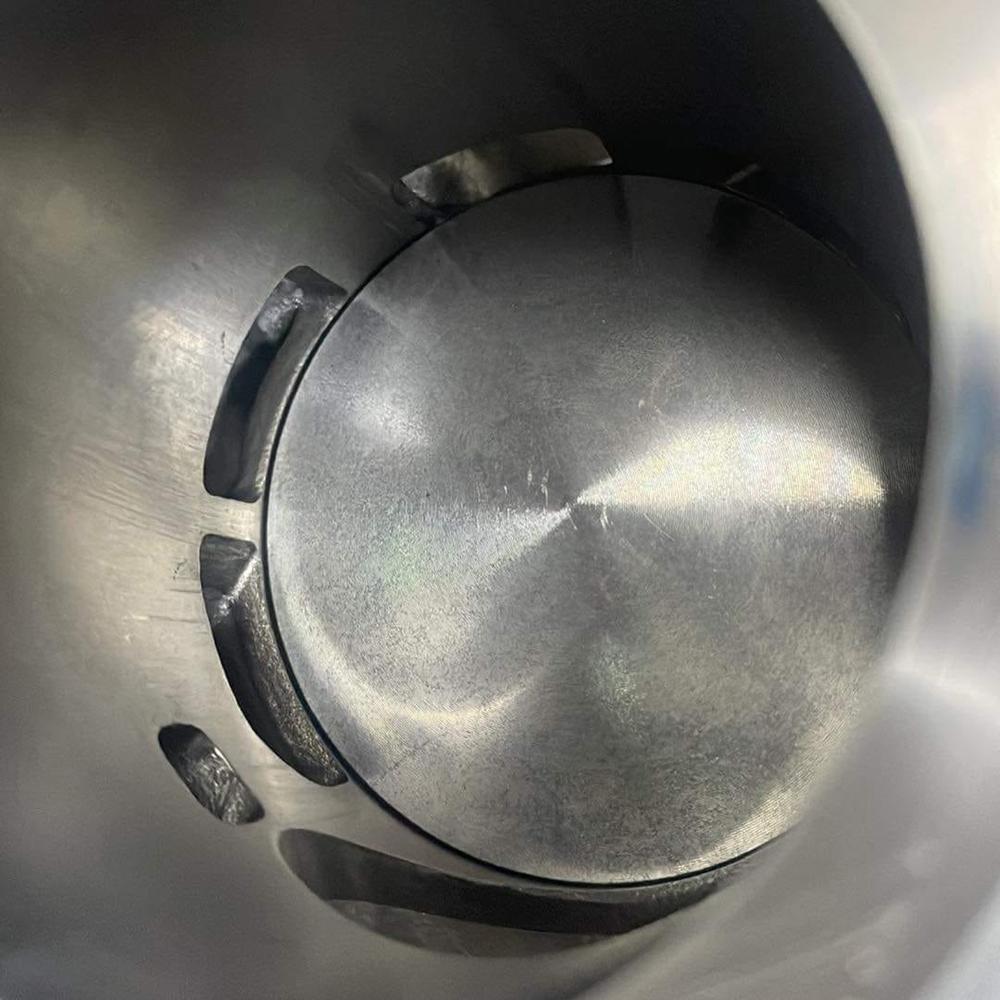

Wire EDM stands out for its ability to produce complex geometries with high tolerances, sometimes within just a few microns. This capability is particularly advantageous for industries requiring intricate designs, such as aerospace and medical. Our team has often utilized Wire EDM to craft components that demand meticulous attention to detail, ensuring our clients receive products that meet precise specifications.

The Art and Science of Wire EDM

From our decades-long experience at Anco Precision, Wire EDM is as much an art as it is a science. The process relies heavily on an electrical current that passes through the wire, creating sparks that erode the material. This is controlled through a liquid dielectric fluid, usually deionized water, which prevents the wire from overheating and assists in flushing away debris.

I recall a challenging project involving a titanium component for a medical device. The precision required was beyond conventional machining, but Wire EDM tackled it with ease. The ability to achieve immaculate, burr-free finishes without inducing stress into the material is one of its most remarkable traits. This process has consistently demonstrated its capacity to meet the most demanding manufacturing challenges.

Applications of Wire EDM

At Anco Precision, the versatility of Wire EDM has opened doors to numerous applications across various sectors. In aerospace, we’ve used it to create components for jet engines and turbine blades, benefiting from its precision and minimal thermal impact on materials. The automotive industry also embraces Wire EDM for developing prototype parts and high-performance components.

Wire EDM’s ability to cut without physical contact ensures that even the most delicate materials are handled with care, a feature particularly appreciated in the production of surgical instruments and implants. The intricate designs possible with Wire EDM have also found favor with artists and designers looking to push the boundaries of metalwork.

Harnessing the Power of Wire EDM at Anco Precision

Reflecting on our journey, Wire EDM has become an indispensable tool in our arsenal at Anco Precision Inc. Our skilled machinists undergo continual training to leverage the latest technology, ensuring that every project meets our high standards for quality and precision. The accolades from our clients are a testament to the commitment we place on delivering exceptional parts, whether they are destined for a car engine or a cutting-edge medical device.

Wire EDM is not just about cutting metal; it’s about shaping possibilities. The capability to execute designs previously thought impossible has solidified our reputation as a trusted partner in the CNC machining industry. Our close collaboration with clients and our passion for achieving precision ensures that Wire EDM remains a cornerstone of our manufacturing processes.

Precision and Versatility of EDM Wire

At Anco Precision Inc., our extensive experience in the CNC machining industry has taught us the incredible value that EDM Wire brings to precision manufacturing. EDM, or Electrical Discharge Machining, is a process that involves using electrical discharges to shape materials, and the wire used in this process plays a critical role in determining the quality and accuracy of the finished product. The right choice of EDM Wire can significantly enhance productivity by ensuring higher metal removal rates and superior surface finish.

Our team at Anco Precision appreciates the ability of EDM Wire to handle complex geometries and precise cuts that would be challenging with conventional tools. In industries like aerospace and medical, where exact specifications are non-negotiable, the use of high-quality, proprietary coated EDM Wire allows us to meet the stringent demands of our clients. Each wire type offers unique benefits, such as improved flushing or enhanced conductivity, contributing to our commitment to deliver 100% precision in every project.

Choosing the Right EDM Wire

As we navigate through diverse projects ranging from custom car parts to medical instruments, choosing the appropriate EDM Wire is a decision guided by various factors. We consider the material of the workpiece, the desired cutting speed, and the complexity of the design. For instance, our machinists often opt for brass wire for general-purpose tasks due to its excellent conductivity and cost-effective nature.

For more specialized applications, our team might select molybdenum wire, especially when working with high-temperature materials. Its high tensile strength and corrosion resistance make it ideal for challenging environments where durability is paramount. The diameter of the wire and the type of coating are also crucial in achieving optimal results. Our experience has shown that a well-chosen wire not only improves efficiency but also reduces waste, aligning with our goals of sustainable and cost-effective manufacturing.

Understanding these nuances allows us to offer expert recommendations to our clients, ensuring that every production requirement is met with the perfect EDM Wire match. This expertise is what sets Anco Precision apart as a leader in the machining industry.

Our Comprehensive Approach to EDM Wire Implementation

One of the standout attributes of our EDM Wire implementation at Anco Precision is our relentless pursuit of innovation and excellence. Our machinists undergo continuous training to stay ahead of technological advancements, enabling them to harness the full potential of EDM Wire in manufacturing. For us, it’s not just about cutting through materials; it’s about crafting solutions that propel our clients’ projects to success.

Our approach is tailored to accommodate the specific needs of each industry we serve. In the automotive sector, for example, precision in wire cutting translates into enhanced performance and safety of vehicle components. Meanwhile, in the aerospace field, every cut requires meticulous attention to detail to adhere to rigorous safety standards. Our proficiency in employing EDM Wire assures our clients that their parts are manufactured to exact specifications, ensuring seamless integration and optimal performance.

Besides the technical aspects, there’s a personal touch to the way we work. As a family-owned business, we treat each project with the dedication and care it deserves, fostering long-lasting relationships with our clients. We take pride in our reputation for reliability and exceptional service, built on decades of delivering consistent quality and quick turnaround times. This holistic approach to EDM Wire application embodies the essence of what Anco Precision represents–precision, quality, and unwavering commitment to customer satisfaction.

The Art and Science of Wire EDM Services

Unpacking the Precision of Wire EDM

In the expansive world of machining, Wire EDM Services stand out as a marvel of precision cutting. From my perspective at Anco Precision Inc., the intricacy of this process continually fascinates me. Wire Electrical Discharge Machining is not merely about cutting; it’s about shaping conductive metals with unparalleled accuracy. Through the electrically charged wire, sparks fly, erosive magic happens, and the material is meticulously etched away to create designs that conventional cutting methods could only dream of.

Our team takes pride in mastering this art. Whether it’s aluminum, stainless steel, or titanium, Wire EDM Services enable us to carve out the most complex geometries without any mechanical stress on the materials. The sheer capability to work with such diverse materials, including hardened steels and exotic alloys, has made Wire EDM an irreplaceable tool in our machining arsenal.

Real-World Benefits of Wire EDM Services

A Multitude of Applications Across Industries

The beauty of Wire EDM Services lies in their versatility. At Anco Precision, we’ve seen this firsthand across a broad spectrum of industries. Consider the aerospace sector; components require exacting tolerances and Wire EDM delivers with precision — every time. Similarly, in the medical field, the need for burr-free, biocompatible instruments is paramount, and here too, Wire EDM is the star performer.

In automotive and marine sectors, where durability and performance are critical, these services create components that fit seamlessly into the high-speed demands of engines and marine vessels. Our expertise ensures that prototypes and production parts alike meet stringent quality standards, which, from a client’s perspective, is invaluable.

Time Efficiency and Cost-Effectiveness

With my experience, I’ve observed how Wire EDM Services significantly reduce lead times and costs. The technology behind it allows for complex shapes to be crafted in a single pass, saving countless hours that would be spent on alternative methods. This efficiency translates not only into reduced costs but also into faster project completions, an aspect that our clients truly appreciate.

Why Choose Anco Precision for Wire EDM Services?

A Legacy of Craftsmanship and Innovation

Choosing Wire EDM Services at Anco Precision means you’re engaging with a legacy of craftsmanship that spans over four decades. Our family-owned business has thrived by marrying traditional skills with cutting-edge technology. It’s this fusion that allows us to offer services to a wide range of industries, ensuring each project is handled with personalized care and attention.

Providing Wire EDM Services is not merely about leveraging technology; it’s about understanding the specific needs of each client. We pride ourselves on offering not just machining capabilities but also bespoke solutions tailored to enhance your product design and functionality.

Commitment to Quality and Precision

Our commitment to delivering 100% precision manifests in every project we undertake. With machinists who undergo extensive training, we guarantee that our work meets the highest standards. This meticulous attention to detail is what sets us apart. Whether you’re bringing in a project with intricate specifications or mass production needs, our Wire EDM Services promise consistency and excellence.

In partnering with Anco Precision for your Wire EDM Services, you not only benefit from our technical expertise but also join a network of satisfied clients who trust us for our reliability and exceptional customer service.

How does Wire EDM work and what are its advantages?

Wire EDM, or Electrical Discharge Machining, is a fascinating process that involves using a thin, electrically charged wire to cut through conductive materials with incredible precision. The wire itself doesn’t touch the material; instead, it creates a series of sparks that erode the material, which is steadily flushed away by a dielectric fluid. This allows us to achieve remarkably tight tolerances and complex geometries, which is especially beneficial for industries like aerospace and medical where precision is crucial. One of the standout advantages is its ability to work with hard materials, such as titanium and hardened steel, without inducing any stress or distortion. This makes it an invaluable tool in our arsenal at Anco Precision.

If you’re interested in the technical details, I highly recommend checking out resources such as this Wikipedia article for a comprehensive overview of EDM methods.

What are some common misconceptions about Wire EDM?

One common misconception is that Wire EDM is too slow for practical use in a production environment. While it’s true that the cutting speed can be slower compared to other methods, the precision and capability to handle complex shapes often make up for this because it saves time in finishing processes, especially when we need burr-free edges. Another misconception is that Wire EDM is too expensive. However, when you consider the accuracy, reduced need for secondary operations, and minimal waste, it often proves to be cost-effective in the long run. Understanding these aspects allows us to be strategic about when and how we implement Wire EDM in projects.

How do you choose the right EDM Wire for a project?

Choosing the right EDM wire is crucial and depends on several factors such as the material being cut, the thickness of the workpiece, and the desired surface finish. At Anco Precision, we typically consider the conductivity of the wire, its tensile strength, and the type of coating it has. For example, brass wire is often selected for general-purpose tasks due to its excellent conductivity and cost-effectiveness, while molybdenum wire is preferred for high-temperature applications due to its strength and resistance to corrosion. Choosing the correct wire not only ensures efficiency but also enhances the precision of the cut. This decision is integral in how we tailor each project to meet exact specifications.

If you’d like to see various wire options and their applications, this resource provides an in-depth exploration of different EDM wire types.

What are the benefits of Wire EDM services for different industries?

Wire EDM services offer a multitude of benefits across various industries. In aerospace, for instance, the precision of Wire EDM ensures that components meet strict safety and performance standards. The medical industry benefits from the burr-free and biocompatible finishes that Wire EDM can provide, essential for surgical instruments and implants. In the automotive sector, the ability to create complex, high-performance parts efficiently is a significant advantage. Our clients in the marine industry also rely on Wire EDM for components that must withstand harsh conditions. The versatility and precision make Wire EDM an indispensable technology in these fields.

For more real-world applications and benefits, dive into Xometry’s overview, which provides insight into how EDM is applied in different sectors.

How does Anco Precision ensure quality in Wire EDM projects?

At Anco Precision, quality assurance is embedded in every step of our Wire EDM projects. We invest heavily in training our machinists to use the latest technologies effectively. Our approach combines advanced equipment with skilled craftsmanship to deliver products that meet stringent specifications. Each project undergoes meticulous planning and quality checks to ensure that the final product not only meets but exceeds customer expectations. Our commitment to precision and detail is what sets us apart, and it’s reflected in the positive feedback we consistently receive from our clients.

If you have more specific questions or want to discuss particular project requirements, we’re always open to connect and provide personalized advice.

Resources

- National Institute of Standards and Technology (NIST) – The NIST website provides valuable information on standards, measurements, and technology to support innovation and industrial competitiveness.

- American Society of Mechanical Engineers (ASME) – ASME is a professional organization that promotes collaboration, knowledge sharing, and skill development in the field of mechanical engineering.

- American Institute of Aeronautics and Astronautics (AIAA) – AIAA is a professional society dedicated to the aerospace industry, offering resources on cutting-edge research and development in aeronautics and astronautics.

- MachiningCloud – MachiningCloud is a platform that provides access to machining tool data, cutting tool information, and resources to enhance manufacturing processes.

- eFunda – eFunda offers engineering fundamentals, resources, and tools for mechanical engineers, providing a wealth of information on various engineering topics.