Screw Machine: Observing the Mechanism of Precision

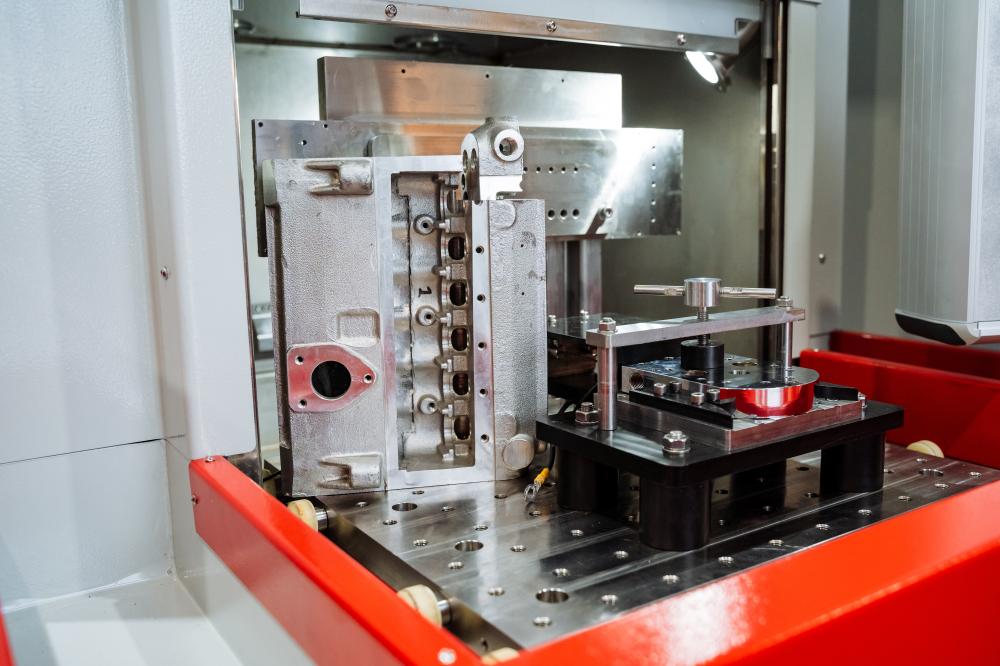

At its core, a Screw Machine is a remarkable piece of engineering that drives the efficiency and accuracy of mass production in machining. These machines, integral to Anco Precision Inc., are designed to perform repetitive machining processes, ensuring every individual component meets exact specifications. The Screw Machine operates either as an automatic lathe or a CNC turning center, each offering unique advantages. As a machinist at Anco Precision, I’ve seen firsthand the unbelievable precision they bring to both simple and complex tasks, from crafting the sleek components of automotive engines to the intricate elements required in aerospace engineering.

In our shop, these machines cut, bore, and thread with near-perfect exactness, essential for industries like medical technology where precision can impact the instrument’s functionality. Our Screw Machine inventory includes both historically significant automatic lathes, driven by mechanical cams, as well as modern CNC-enabled centers, which use electronic automation for unparalleled flexibility and control. Every piece we create tells a story of mechanical brilliance, right from the moment the raw material is fed into the apparatus.

Applications of Screw Machines in Modern Industries

Screw Machines are versatile and can serve a multitude of industries, a fact that underlines their universal applicative nature. At Anco Precision, these machines are at the heart of producing components for sectors as varied as marine, automotive, medical, and aerospace. Each application demands specific attention to detail, something our Screw Machines are equipped to handle with ease.

From custom car parts to critical components of medical devices, the role of Screw Machines cannot be overstated. These machines enable us to turn intricate designs into tangible products, a process I’ve watched evolve and refine over my years in this field. The adaptability and precision offered by these machines make them indispensable for creating high-quality, consistent output, essential for meeting the stringent standards set by various industries.

Anco Precision’s portfolio includes a vast array of products made possible through Screw Machining, highlighting the adaptability of these machines to diverse project requirements. Whether it’s the robust parts of watercraft or the delicate features of optical devices, Screw Machines have proven their mettle time and again.

Navigating the Technicalities: Screw Machine Functionality

Diving into the technical realm, understanding how a Screw Machine operates can be quite a fascinating journey. These machines, particularly the CNC variants, function through computer numerical control, which integrates cutting-edge technology with traditional machining principles. I’ve had the pleasure of working with both old-school machines and their modern counterparts, each offering a glimpse into the evolution of manufacturing technology.

Our CNC Screw Machines at Anco Precision are a marvel of modern engineering. They boast speed, accuracy, and consistency, vital for projects demanding high precision. The machines are driven by software that allows for the automatic control of machining tools and 3D printers, turning digital designs into physical forms. These capabilities are particularly crucial in sectors such as aerospace and medical equipment manufacturing where even the slightest deviation can lead to significant repercussions.

The older cam-driven Screw Machines, while less prevalent, maintain a charm of their own with their mechanical intricacy and robustness. Seeing these mechanical wonders in action is like watching a symphony of gears and levers perform in harmony, a sight any machinist can appreciate.

This duality between the past and present in Screw Machine technology offers machinists like me a unique perspective on precision engineering. Each project I’ve undertaken has reinforced my appreciation for these machines and their essential role in the manufacturing landscape.

Personal Insights: An Insider’s Perspective on Screw Machines

Having spent countless hours in the hum of the machine shop at Anco Precision, I’ve developed a profound respect for the Screw Machine and its capabilities. Each precision-cut part we produce is not just a product but a testament to the intricate dance between human innovation and mechanical prowess. The machines might be the stars of the show, but it is the machinists who tune and tweak them to perfection, ensuring they perform at peak capacity.

One memorable project involved crafting components for a complex electronic device. The task demanded an extraordinary level of detail and precision, which our Screw Machines delivered flawlessly. Observing the finished parts being assembled into a functional product was a satisfying culmination of our collective expertise and the machine’s capabilities.

Anco Precision’s commitment to precision and quality is mirrored in the way we operate our Screw Machines. This dedication has earned us high praise from clients who value not only the quality of our products but also the efficiency and reliability with which we deliver them. In a field where precision is paramount, Screw Machines are not just tools; they are extensions of our craft.

In sum, Screw Machines are the unsung heroes in the world of machining, a sentiment that resonates deeply with those of us who work with them daily. Each piece we produce is a small tribute to their indispensable role in shaping the future of manufacturing.

Choosing a Local Screw Machine Shop

Quality Expertise Matters

When searching for a screw machine shop near me, the quality of service and expertise stands as a pivotal consideration. With over 40 years in the industry, Anco Precision Inc. leads the way in providing precision machining services. The machinists are not just operators but dedicated craftsmen who understand the intricacies of CNC milling and screw machining. Their extensive training equips them with the skills to deliver products with meticulous attention to detail across various industries.

Working with a team that values precision over volume ensures that each project is treated with individualized attention. This nuanced approach means whether you’re looking for custom car parts or advanced medical instruments, quality isn’t compromised. Stories from customers highlight the difference a highly skilled team can make, transforming basic requests into high-quality, end-use components.

Variety of Services Offered

In the quest for a trusted screw machine shop near me, it’s essential to consider the range of services offered. Anco Precision doesn’t just specialize in a singular facet of machining; they provide comprehensive solutions like CNC turning, rapid prototyping, and precision screw machining. From aerospace to automotive, their versatility allows for handling a wide array of manufacturing requirements.

This diversity of services means that whether you’re a government entity needing sophisticated aerospace components or a small business seeking durable electronic enclosures, Anco Precision has the capability to meet those needs. Their ability to manage diverse projects is enhanced by their use of state-of-the-art equipment, ensuring efficient and accurate production timelines.

Customers often emphasize the seamless process of working with Anco Precision, where submitting a simple drawing file can lead to an instant quote–streamlining what could otherwise be a lengthy back-and-forth. The emphasis on ease of access without sacrificing quality sets them apart in the competitive landscape of precision machining.

Benefits of a Local Machine Shop

Community and Accessibility

Opting for a screw machine shop near me offers tangible benefits beyond just convenience. Being able to physically visit a shop like Anco Precision in Deerfield Beach allows for a more personal interaction, fostering a community relationship not possible with distant providers. This proximity means faster response times to inquiries and more efficient communication, leading to quicker project turnaround times.

Customer-Centric Approach

Anco Precision’s commitment to customer satisfaction is unwavering, driven by a family-owned ethos that prioritizes client relationships. Customers experience this dedication through competitive pricing, timely deliveries, and an unyielding commitment to high standards of quality. The testimonials speak volumes, with clients repeatedly highlighting the reliable service and robust support they receive.

Living in the same community as your service provider can lead to better alignment of values and business goals. When you choose a local screw machine shop near me, you engage with a partner who comprehends the needs and challenges of the local market, further enhancing collaboration and innovation within your projects.

Innovative Tools and Techniques

State-of-the-Art Equipment

A critical aspect to consider when evaluating a screw machine shop near me is the technological infrastructure they employ. Anco Precision stands out with their state-of-the-art equipment that not only ensures precision but also facilitates rapid prototyping. This allows for quick adjustments and refinements, catering to the evolving demands of industries like medical and aerospace. Their fleet of machinery is complemented by a team that remains at the forefront of technical skills, ensuring every output is both innovative and reliable.

Practical Insights from Industry Experience

Decades of experience in the machining industry provide Anco Precision with an edge in understanding and catering to varied customer needs. This practical insight is invaluable, guiding new projects towards successful completion. The team’s familiarity with both traditional and modern techniques means they’re equipped to tackle unique challenges that arise during production, offering bespoke solutions rather than one-size-fits-all approaches.

Ultimately, choosing the right screw machine shop near me is about recognizing the value of expertise, reliability, and an unyielding commitment to excellence. The intersection of cutting-edge technology and hands-on experience at Anco Precision assures clients of high-quality outcomes, tailored to their specific project demands.

What Are Screw Machine Shops?

Screw Machine Shops Florida are specialized manufacturing facilities that utilize screw machines to produce high-precision, high-volume parts. These shops cater to a wide array of industries, ranging from automotive to aerospace, ensuring that each component meets exact specifications. Screw machines, primarily CNC operated in modern shops, offer versatility and efficiency, producing parts with intricate details at a rapid pace.

Operators in these facilities undergo rigorous training to handle sophisticated equipment that can work with various materials including metals, plastics, and composites. With the ability to run multiple spindles simultaneously, these machines can perform numerous operations such as turning, drilling, and threading, all in a single setup. As a result, Screw Machine Shops Florida can deliver consistent, high-quality components in large quantities while minimizing lead times.

- High-volume production capabilities

- Precision in crafting intricate parts

- Adaptability to diverse materials

Personal Experiences in the Industry

Having spent over four decades at Anco Precision Inc., a well-regarded name in Screw Machine Shops Florida, I’ve witnessed firsthand the evolution of precision machining. Our shop, nestled in Deerfield Beach, FL, has been a hub of innovation and excellence, shaping the future of manufacturing. The journey from manual lathes to state-of-the-art CNC machines has been nothing short of transformative.

The dedication to precision is palpable in every aspect of our work. Our team’s commitment to maintaining stringent quality standards has fostered trust among clients spanning the marine, medical, and aerospace industries. The feedback we receive often highlights our attention to detail and the seamless integration of customer feedback into our processes. Collaborating with talented machinists has indeed been an inspiring chapter of personal and professional growth.

Addressing Diverse Needs

A unique aspect of Screw Machine Shops Florida, as seen at Anco Precision, is the ability to cater to diverse manufacturing requirements. Whether it’s prototyping a new automotive component or mass-producing medical instruments, our facility is equipped to handle it all. The versatility of our operations is a testament to our team’s adaptability and expertise.

One memorable project involved crafting a series of custom engine components for a niche automotive client. The challenge was to deliver exact replicas while integrating a new material specification to enhance performance. Through collaborative problem-solving and leveraging our CNC capabilities, the project was not only successful but also led to a long-term partnership.

In addition to custom solutions, we provide swift service with our online quoting system. By allowing clients to upload their design files for instant quotes, we’ve significantly reduced the preliminary phase of project initiation, enabling quicker turnaround times and fostering efficient communication.

The Future of Screw Machine Shops

Looking ahead, the future of Screw Machine Shops Florida is bright, driven by advances in technology and an unwavering commitment to quality. The integration of AI and machine learning could soon revolutionize CNC machining, offering predictive maintenance and optimized production schedules. At Anco Precision, we are eager to embrace these innovations while maintaining our core values of precision and customer satisfaction.

As industries continue to evolve, so do the challenges and opportunities that come with them. Our role in the supply chain is more crucial than ever, as we bridge the gap between concept and reality. By continuously refining our techniques and expanding our capabilities, Screw Machine Shops Florida will remain pivotal in supporting diverse sectors and stimulating industrial growth across the state.

- Emerging trends in CNC machining

- Potential of AI in enhancing production

- Commitment to quality and innovation

What is a Screw Machine?

A screw machine, quite aptly, is a marvel of precision engineering primarily used for the mass production of intricate parts. Imagine you’re crafting components for an automotive engine; a screw machine can automatically perform tasks like cutting, drilling, and threading to create parts that fit exact requirements. Modern machines often operate as CNC turning centers, which enhance flexibility and accuracy with digital control systems, simplifying complex tasks and reducing human error. Historically, these machines have played a central role in industries ranging from aerospace to medical technology, where precision is non-negotiable. If you’re curious about how old and new technologies mesh, consider visiting a machine shop to witness these mechanical wonders firsthand.

How do Screw Machines Impact Modern Industries?

Screw machines are the backbone of many modern industries due to their ability to produce high-precision components with consistency. Take the medical device sector, for example, where a misaligned part can lead to significant issues. Screw machines ensure that each piece, whether for surgical tools or implants, meets stringent quality standards. The automotive and aerospace industries also rely heavily on these machines for parts that require durability and precision. For a real-world example, think about how the transportation industry has evolved. With screw machines, companies can prototype and produce customized parts rapidly, enabling quicker advancements and innovations. For those with an interest in engineering or manufacturing, exploring how these machines operate can offer deep insights into industrial efficiencies.

What are the Key Differences Between CNC and Traditional Screw Machines?

The difference between CNC and traditional screw machines lies primarily in their operation and capability. CNC screw machines utilize computer numerical control to manage machining tools, allowing for precise, automated production. This setup means that once a design is programmed, the machine can execute complex tasks with minimal manual intervention. On the contrary, traditional screw machines, often cam-driven, require direct physical manipulation. While they have a rich history of robustness and reliability, they lack the modern CNC’s flexibility and speed. If you’re considering starting a manufacturing project, understanding these differences can help you choose the right equipment. Visit a local CNC shop to see these machines in action, and you’ll get a feel for how technology enhances production.

How do Screw Machines Enhance Manufacturing Efficiency?

Enhancing efficiency is one of the primary advantages of screw machines–these devices streamline the production of complex parts by integrating several machining steps into one. For instance, if you’re manufacturing custom bike parts, a screw machine can handle cutting, threading, and boring in a single operation cycle. This minimizes manual handling, reducing the time and cost associated with multi-machine setups. At Anco Precision, I’ve seen how the integration of advanced CNC technology has allowed us to meet tight deadlines without sacrificing quality. For businesses considering how to improve production efficiency, exploring the capabilities of modern screw machines offers a practical solution.

Why is Precision Important in Screw Machining?

Precision in screw machining is crucial because it directly impacts the functionality and reliability of the finished product. Consider the aerospace industry–when you’re dealing with aircraft parts, even a minuscule deviation can compromise safety. At Anco Precision, we strive for 100% precision to ensure that every component, whether for marine or medical use, meets the highest standards. This commitment is reflected in every product we deliver, ensuring customer satisfaction and trust. If precision intrigues you, visiting a machine shop can provide a tangible sense of how minute details are meticulously controlled to achieve perfection.

How to Choose a Local Screw Machine Shop?

Selecting a local screw machine shop involves considering several factors, including expertise, equipment, and the range of services offered. Look for a shop with a solid track record–like Anco Precision, known for its over 40 years of excellence. A visit can reveal insights into their capabilities, such as whether they offer CNC and traditional machining, rapid prototyping, and comprehensive project solutions. Engaging with local professionals can also foster stronger community ties and enhance communication, contributing to more personalized service. Have you thought about checking reviews and testimonials? These can provide an unbiased look at customer satisfaction and service quality, guiding your decision-making process.

What are the Benefits of Using a Local Machine Shop?

Utilizing a local machine shop offers numerous benefits, including convenience, expertise, and support for local businesses. When working with a nearby shop like Anco Precision, you benefit from face-to-face interactions, which can clarify project specifications and timelines. Additionally, local shops tend to offer faster turnaround times due to reduced shipping needs. There’s also the aspect of supporting your local economy, which can have far-reaching community benefits. So if you’re embarking on a new project, why not consider visiting a local machine shop and discussing your needs directly? You might find that the personalized service adds significant value to your manufacturing operations.

What Does the Future Hold for Screw Machine Shops in Florida?

The future of screw machine shops in Florida looks promising, thanks to continuous technological advancements and an ever-growing demand for precision machining. As industries such as aerospace and medical technology progress, the need for highly precise components will increase. Anco Precision is poised to embrace trends like AI integration and machine learning, which can optimize machining processes and predictive maintenance. Are you following the trends in CNC advancements? Keeping abreast of these developments could provide a significant edge in selecting partners for your machining needs.

Resources

- National Institute of Standards and Technology – Official website of NIST providing resources on standards, technology, and innovation.

- NASA Procurement Data System – Access NASA’s procurement data system for information on contracts and vendors.

- Engineering Toolbox – A comprehensive resource for engineering professionals with tools, information, and resources.

- MadeHow – Learn how everyday products are made through detailed explanations and illustrations.

- National Association of Wholesaler-Distributors – Resources and advocacy for wholesaler-distributors in various industries.