Precision Machining Unveiled: A Closer Look at the Craft

Having spent several decades in the precision machining industry, the team at Anco Precision Inc. understands the intricate craft behind turning raw materials into meticulously engineered components. Production Machining is not just about cutting and shaping; it’s an art form that combines technical prowess with an eye for detail.

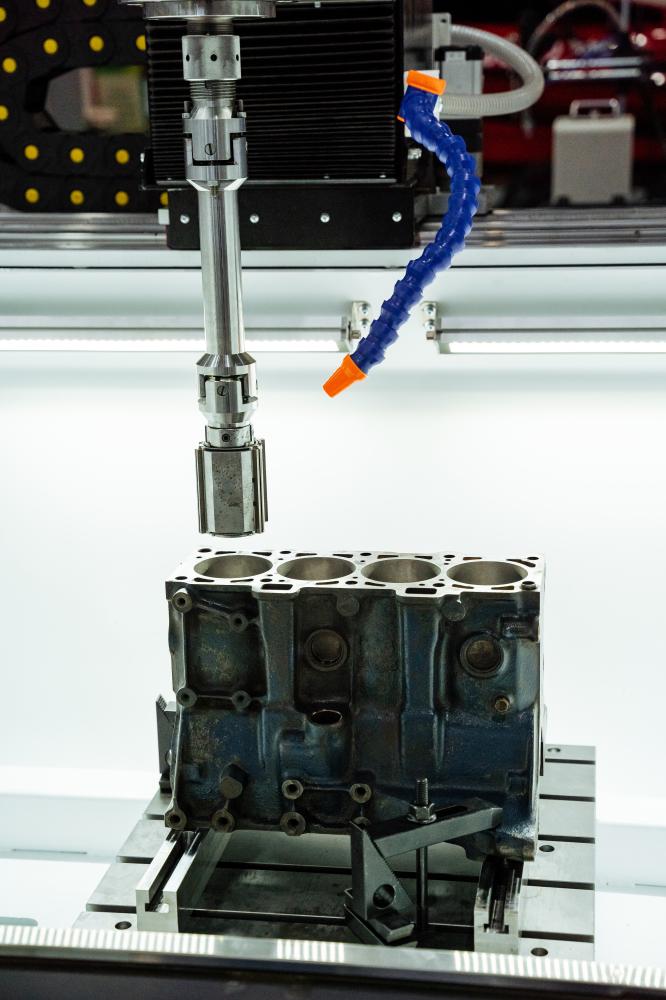

In the bustling world of CNC machining, perfection is not an aspiration–it’s a requirement. Every piece we create, from automotive engine components to intricate medical instruments, demands a harmonized blend of precision and efficiency. Our machinists, thoroughly trained in operating cutting-edge equipment, epitomize this ethos with every project they undertake.

What makes Production Machining fascinating is the diverse range of industries it caters to, spanning marine, automotive, aerospace, and more. Each sector brings its own unique set of challenges and opportunities, allowing us to continuously innovate and refine our craft.

How Advanced Technologies are Shaping Production Machining

The evolution of CNC technology has revolutionized Production Machining, transforming traditional processes with state-of-the-art advancements. At Anco Precision, we embrace these changes, leveraging CNC milling, CNC turning, rapid prototyping, and screw machining to exceed the demands of modern manufacturing.

Key technological advancements include:

- Automation: Streamlines operations, reduces human error, and enhances productivity across the board.

- 3D Modeling: Allows for precise visualization and prototyping, minimizing waste and optimizing resource use.

- AI Integration: Enhances machine efficiency and aids in predictive maintenance, significantly reducing downtime.

These technologies are not just tools; they’re transformative forces that have redefined what’s possible in the realm of Production Machining. Our team continually adapts and upgrades to remain at the forefront, ensuring every part we produce meets our high standards of excellence.

Anecdotes from the Shop Floor: Real-World Lessons

Working at Anco Precision offers endless opportunities to witness firsthand the impact of top-notch Production Machining. I recall one project where a last-minute design change necessitated rapid adaptation. Our machinists swiftly recalibrated the CNC equipment, turning potential disaster into triumph, all within an afternoon. This adaptability and resourcefulness are hallmarks of our operations.

Another memorable instance involved a bespoke medical device where precision was non-negotiable. The client provided specifications with micron-level tolerances, presenting a formidable challenge. However, our meticulous approach and attention to detail ensured we delivered a flawless product, winning the client’s trust and establishing a long-term partnership.

These stories underscore the human element inherent in Production Machining at Anco Precision. Beyond the machines and technology, it’s our people–our skilled machinists and engineers–who drive our success. Their dedication and ingenuity breathe life into every component we produce, setting Anco Precision apart as a leader in the industry.

The Human Element: Skill and Dedication

In the world of Production Machining, technology is only as effective as the people who wield it. At Anco Precision, our team is our greatest asset, bringing a wealth of experience and an unwavering commitment to quality to every project. Our machinists are not just operators; they are craftsmen, passionate about their work and dedicated to continuous improvement.

Training is a cornerstone of our operations, ensuring our team remains at the leading edge of industry developments. By fostering a culture of learning and innovation, we empower our employees to take ownership of their work, leading to exceptional results.

The personal insights and stories shared by our team members provide a glimpse into the day-to-day realities of Production Machining. They highlight the challenges and triumphs that define our journey, reinforcing the intricate dance between man and machine that lies at the heart of our success.

Precision Machining in Practice

At Anco Precision, a family-owned Production Machine Shop in Deerfield Beach, FL, precision is not just a promise; it’s a practice honed over 40 years. Our commitment to quality in CNC machining reflects in every product, whether it’s crafted for marine, automotive, or medical use. Our machinists, who undergo extensive training, are adept at operating sophisticated equipment, ensuring that each part meets stringent industry standards. This dedication to excellence is evident in our reputation for delivering products with impeccable accuracy.

Our Production Machine Shop is a versatile hub of innovation. We specialize in CNC milling, CNC turning, and rapid prototyping, offering services tailored to meet diverse production needs. Customers commend our ability to handle an array of projects, from custom car parts and medical instruments to aerospace components. The agility of our processes allows us to serve a broad clientele, including government agencies, universities, and small enterprises, underlining our capacity to adapt and excel.

Customer-Focused Approach

The heart of Anco Precision’s Production Machine Shop lies in its customer-centric philosophy. Our team is dedicated to delivering products that not only meet but exceed client expectations. Testimonials from our wide-ranging clientele highlight our swift delivery times and competitive pricing, attributes that are crucial in today’s dynamic market. Our seamless service is further enhanced by offering instant online quotes, streamlining project initiation for our clients, and making precision manufacturing more accessible.

Partnerships at Anco Precision are built on trust and reliability. Our clients appreciate the personalized attention and the depth of expertise we bring to each project. Whether manipulating complex designs or executing straightforward tasks, our Production Machine Shop remains a beacon of consistency and quality. Our facility is equipped to tackle projects of any scale, from prototyping to full-scale production, reinforcing our reputation as a trusted partner in the machining industry.

We ensure transparency and foster long-term relationships by engaging closely with our clients through the entire manufacturing process. By doing so, we are able to anticipate and meet the precise demands of each project, ensuring customer satisfaction at every step.

Innovative Solutions and Sustainability

In the evolving landscape of machining, innovation is key. Our Production Machine Shop constantly seeks out new methods and technologies to enhance efficiency and precision. Embracing the latest advancements in CNC technology and robotics ensures that we remain at the forefront of industry trends. However, it’s not just about technology; our team’s creativity and problem-solving abilities allow us to devise unique solutions tailored to complex challenges.

Environmental responsibility is another cornerstone of our operations. Anco Precision implements sustainable practices across our Production Machine Shop, such as recycling materials and optimizing resource use. By prioritizing sustainability, we align our operational goals with environmental stewardship, contributing positively to both our community and the broader global ecosystem.

Our journey in the world of precision machining is guided by a passion for innovation and a steadfast commitment to quality and sustainability. Anco Precision stands as a testament to the impact a dedicated Production Machine Shop can have–not only in terms of exceptional products but also in shaping a better future for the industry and the environment alike.

Unique Challenges in Low Volume Production

In the intricate world of machining, Low Volume Production Machining is a realm where expertise truly shines. Unlike mass manufacturing, it demands an unrivaled focus on precision and customization, tailored to proffer unparalleled quality. At Anco Precision Inc., we understand these nuances because, in our four-decade journey, we’ve learned to blend craftsmanship with engineering excellence.

The key challenge in Low Volume Production Machining lies in adapting to frequent design changes and stringent quality requirements. Our machinists are adept at using state-of-the-art equipment to tackle these obstacles. By ensuring meticulous attention to detail, we craft parts that meet the bespoke needs of industries ranging from aerospace to medical devices.

Personal experiences have taught us that a hands-on approach is vital. For instance, in our work with the marine industry, customizing components that can withstand harsh environments is a frequent demand. This testing ground has honed our skills in balancing precision and durability in every project we undertake.

Solutions with CNC Technologies

The quest for precision and customization often leads to the utilization of cutting-edge solutions like CNC machining. At Anco Precision Inc., Low Volume Production Machining benefits greatly from our investment in advanced CNC milling and turning. These technologies allow us to maintain high accuracy while efficiently managing smaller production runs.

Experience has taught us the importance of flexibility in CNC operations. Whether it’s crafting a batch of custom enclosures for an electronics project or producing intricately detailed parts for optical devices, our team leverages CNC technology to ensure both quality and adaptability. This dual benefit makes CNC a preferred choice for many clients.

Additionally, rapid prototyping plays a pivotal role in refining designs and speeding up the product development cycle. We’ve seen how integrating rapid prototyping into our projects can turn ideas into tangible results swiftly, aligning perfectly with the dynamic needs of today’s market.

Our commitment to Low Volume Production Machining extends to offering instant quotes via our online platform. This service empowers clients to plan and budget effectively, ensuring their projects move from concept to creation without delays.

Embracing Innovation and Efficiency

At Anco Precision, innovation and efficiency are not just buzzwords; they are the cornerstones of our approach to Low Volume Production Machining. By embracing new technologies, we continually enhance our capabilities, delivering superior results to industries such as automotive and aerospace where precision is paramount.

Our journey in Low Volume Production Machining has shown us that agility is crucial. As the demand for rapid response increases, our commitment to staying ahead of technological advances ensures we remain a leader in the field. This forward-thinking mindset allows us to help clients navigate the complexities of modern manufacturing with ease.

Drawing from our rich history, we understand that collaboration is key to achieving outstanding results. By maintaining open lines of communication with our clients, we ensure every element of their vision is captured and realized. This collaborative spirit is what makes Anco Precision an invaluable partner in Low Volume Production Machining.

What are the common misconceptions about Production Machining?

Many people assume that production machining is purely automated and devoid of the human touch. While advanced technologies like CNC and AI integration play a significant role, the skill and intuition of machinists are crucial to creating high-quality components. At Anco Precision, each machinist is integral to ensuring precision and addressing industry-specific challenges. Additionally, some believe machining is only suited for mass production. On the contrary, precision machining is highly effective for low-volume, custom, and high-complexity parts as well. Understanding the balance between technology and craftsmanship can be eye-opening for many.

How are advanced technologies reshaping Production Machining?

Advanced technologies such as automation, 3D modeling, and AI are transforming production machining by enhancing efficiency and precision. At Anco Precision, we’ve integrated these technologies to streamline operations and minimize errors. Automation, for instance, reduces manual intervention, allowing for safer and faster production processes. 3D modeling and rapid prototyping are indispensable for visualizing and testing components before full production, reducing waste. AI, on the other hand, aids in predictive maintenance, ensuring machines run optimally. These advancements not only boost productivity but also open doors to innovative design possibilities, consistently pushing the boundaries of what can be manufactured.

Why is the human element important in precision machining?

Despite the high level of automation in modern machining, the human element remains crucial. At Anco Precision, our machinists are not just operators; they are craftsmen whose experience and intuition play a pivotal role in quality control and problem-solving. Machines can follow instructions, but it’s the human touch that adapts to unforeseen challenges and makes critical decisions. For instance, making minute adjustments for a bespoke medical device requires expert judgment, which comes from years of hands-on experience. This human-machine synergy ensures that the final product meets stringent quality standards and client expectations.

How does a customer-focused approach benefit the Production Machine Shop?

At Anco Precision, adopting a customer-focused approach means building strong partnerships based on trust and communication. By understanding our clients’ needs and challenges, we tailor our services to deliver precise and timely solutions. This approach not only fosters loyalty but also encourages collaboration, leading to innovative outcomes. For example, by engaging closely with clients throughout the manufacturing process, we can anticipate potential hurdles and address them proactively. Our commitment to transparency and personalized service helps ensure that projects not only meet but often exceed expectations, strengthening our reputation as a reliable partner in machining.

What challenges are unique to Low Volume Production Machining?

In low-volume production machining, precision and customization take center stage. Unlike mass production, each part may require significant attention to detail and frequent adaptations to design changes. At Anco Precision, we’ve mastered this art by blending craftsmanship with advanced CNC technologies. For instance, creating custom components that withstand harsh marine environments involves balancing precision with durability–a task that demands both technical expertise and creative problem-solving. Embracing these challenges leads to high-quality, bespoke products that meet stringent industry standards.

How do CNC technologies support Low Volume Production Machining?

CNC technologies are vital in achieving the precision and flexibility required for low-volume production machining. At Anco Precision, CNC milling and turning allow us to maintain high accuracy even in smaller production runs. Such technologies are essential when producing custom enclosures for electronics or detailed parts for optical devices. The adaptability of CNC machinery supports complex designs and rapid prototyping, ensuring that ideas can be quickly brought to life and refined. This flexibility is particularly valuable when dealing with frequent design changes, characteristic of low-volume projects.

How does innovation impact efficiency in Production Machining?

Innovation in production machining leads to enhanced efficiency and productivity. By embracing cutting-edge technologies and methodologies, Anco Precision continually stays ahead of industry trends. This not only allows us to deliver superior results but also helps streamline operations, reducing lead times and costs. Innovations such as automated systems and advanced CNC technologies enable faster processing, while also maintaining high precision and quality. By fostering a culture of innovation, we empower our team to solve complex challenges creatively, ensuring our clients receive not only efficient but also top-quality products. This approach drives continuous improvement and competitive advantage.

Reflecting on these advancements, what other ways do you think innovation can influence your industry? Feel free to share your thoughts or questions in the comments below.

Resources

- Bureau of Labor Statistics – The Bureau of Labor Statistics provides data and analysis on various industries, including manufacturing and machining.

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory federal agency that promotes innovation and industrial competitiveness through advancements in technology.

- National Academies Press – The National Academies Press publishes reports and resources on a wide range of topics, including engineering and manufacturing.

- National Science Foundation (NSF) – The NSF funds research and education in various fields of science and engineering, including precision machining.