What is EDM Machining?

EDM Machining, or Electrical Discharge Machining, is a cutting-edge technique used primarily for precision engineering tasks that traditional methods cannot handle. At Anco Precision Inc., with over four decades of experience, I’ve personally witnessed how EDM can transform raw materials into meticulously crafted components. This process is a non-contact method that employs thermal energy to remove material from a workpiece, allowing for intricate designs and complex shapes without compromising on accuracy.

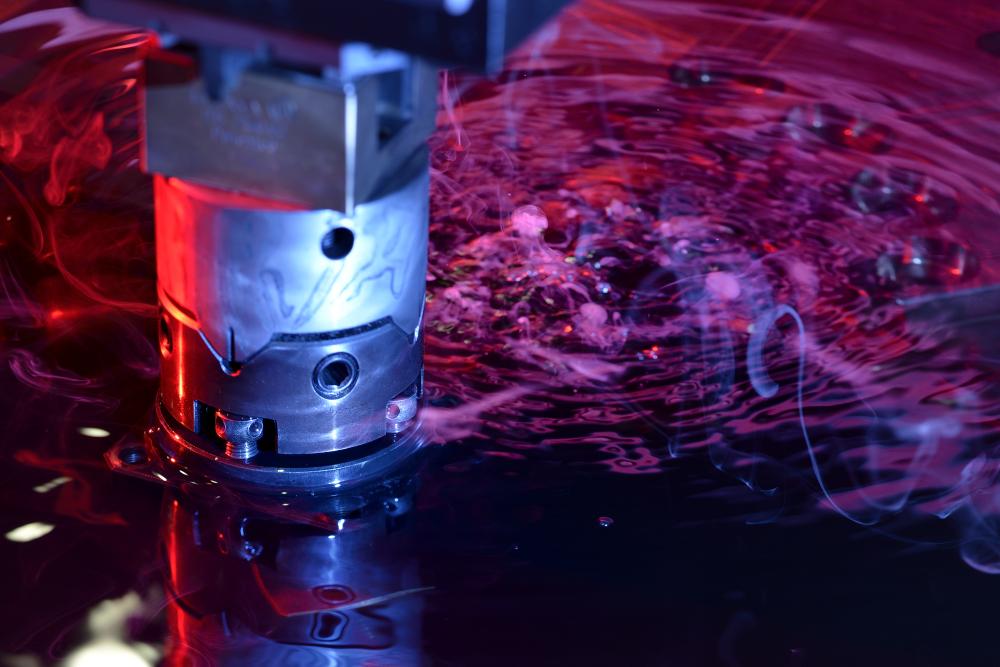

The technology behind EDM Machining is fascinating. It involves an electrical discharge between an electrode and the workpiece, which is submerged in a dielectric fluid. This creates a series of rapid, controlled sparks that erode the material. The beauty of this method is that it allows for extremely precise work on hard materials such as steel, tungsten, and titanium, which are often used in the aerospace and medical industries. The precision and capability to machine such materials make EDM a preferred choice for projects that demand high accuracy and fine details.

Types and Techniques of EDM Machining

Die-Sinking EDM

I recall a project where we utilized die-sinking EDM to produce complex mold cavities at Anco Precision Inc. Die-sinking EDM, also known as ram EDM, involves an electrode shaped as the negative of the desired geometry. The electrode is gradually lowered into the workpiece, removing material through electrical discharges. This process is ideal for creating intricate details in molds and dies, offering unrivaled precision.

Wire EDM

Wire EDM provides a unique advantage in machining delicate, intricate parts without any physical contact. It’s akin to using a wire cheese cutter, where a thin, electrically charged wire cuts through the material. This technique was pivotal in one of our projects for the marine industry, where we needed to ensure the flawless production of components with very tight tolerances. The wire EDM process allowed us to achieve these requirements effortlessly, thanks to its ability to cut complex shapes with high accuracy.

Hole-Drilling EDM

Hole-drilling EDM is indispensable for applications requiring small, precise holes. At Anco Precision, we used this method to drill holes for a medical device prototype. This approach allowed us to create burr-free, deep holes that were crucial for the device’s functionality. The precision and cleanliness of this EDM variant make it an excellent choice for such sensitive applications.

Challenges and Opportunities in EDM Machining

EDM Machining, while highly effective, presents certain challenges. One of the most significant hurdles is the energy intensity and the time it takes for the process. While working on large batches, such as automotive components, the energy consumption becomes noticeable. However, the precision and ability to work on hard materials make it worthwhile.

Another challenge lies in the technical expertise required to operate EDM equipment. At Anco Precision, we emphasize continuous training, ensuring our machinists are adept at handling this state-of-the-art technology. This approach not only enhances the quality of our output but also elevates the skill set of our workforce, preparing them for advanced machining tasks.

Despite these challenges, EDM Machining offers numerous opportunities. Its ability to machine hard materials makes it invaluable across various industries like aerospace and medical. Companies like ours can leverage this technology to carve a niche in the market for precise and complex parts, which traditional machining cannot achieve. The versatility and precision of EDM continue to push the boundaries of what is possible in manufacturing.

Personal Insights and Experiences with EDM Machining

Having worked at Anco Precision for several years, I’ve seen first-hand how EDM Machining can revolutionize the manufacturing process. There was an instance where we needed to create a precision component for an automotive client that required extremely tight tolerances. The client was initially skeptical, given their past experiences with other machining services. By employing EDM Machining, we not only met their tolerance requirements but delivered the parts ahead of schedule, showcasing the capability and efficiency of our processes.

Another memorable project was a collaboration with a medical technology firm, where we utilized EDM to produce components that were critical to the performance of biomedical devices. Each component had to meet rigorous standards for accuracy and surface finish. It’s experiences like these that highlight the profound impact EDM has on high-stakes industries, where precision is not just preferred but paramount.

In my personal view, EDM Machining is not just a tool, but a testament to human innovation and the relentless pursuit of perfection in manufacturing. It continues to challenge us, pushing our skills and capabilities to new heights, and providing opportunities to deliver products that are nothing short of remarkable.

Precision in EDM Wire Cutting

At Anco Precision Inc., we take pride in our mastery of EDM Wire Cutting, a quintessential process in the CNC machining landscape. With over four decades of experience, our team has honed the techniques necessary to achieve 100% precision, a standard we uphold across all our projects. Though primarily used in the aerospace, automotive, and medical industries, EDM Wire Cutting has proven invaluable for custom solutions in an array of sectors, thanks to its capability to produce intricately detailed parts with minimal material wastage.

The process of EDM Wire Cutting involves the use of a thin, electrically conductive wire to erode material from the workpiece. This is achieved through a series of rapidly recurring electrical discharges between the wire and the workpiece, which are akin to small sparks. Our machinists, trained rigorously, operate state-of-the-art equipment to manage this delicate balance effectively. The result is an unparalleled precision that meets the meticulous demands of high-quality production machining.

Innovative Approaches and Benefits

The versatility of EDM Wire Cutting is highlighted by its inclusive application across diverse materials, from hardened steel to superalloys. This adaptability makes it an indispensable tool at Anco Precision Inc., where we cater to the specific needs of each client. Our innovative approaches have allowed us to overcome traditional limitations, expanding the scope of what is achievable in complex part production.

One of the pivotal advantages of EDM Wire Cutting is its ability to create precise cuts in hard materials where traditional machining would falter. This opens new avenues for design and functionality in parts that require exceptional accuracy. With minimal thermal effects, there is a reduced risk of altering the material’s properties, ensuring the integrity of the finished product. Our clients often engage us for projects demanding exactitude, such as creating intricate surgical instruments or components for aerospace applications.

Another remarkable benefit is the optimization of material use, as the process is non-contact and removes material with minimal waste. This efficiency not only reduces costs but also aligns with the growing emphasis on sustainable manufacturing practices, something we strive to incorporate at Anco Precision Inc.

Personal Experiences and Insights

Having witnessed the evolution of EDM Wire Cutting firsthand, I am continually impressed by its transformative impact on manufacturing. When I started at Anco Precision Inc., I was particularly fascinated by how this technology could replicate the precision of hand-crafted parts at scale. Each project brought new challenges and insights, demonstrating the incredible potential of EDM Wire Cutting to revolutionize production methods.

One memorable project involved crafting a series of miniaturized, intricate components for a robotics prototype. Each component required unmatched precision to ensure flawless interaction within the device. The success of this project reinforced my belief in the capabilities of EDM Wire Cutting to push the boundaries of what we can achieve in precision machining.

Working with clients from diverse industries has also provided opportunities to explore unique applications of EDM Wire Cutting. From assisting small inventors seeking to bring their creations to life, to partnering with large aerospace firms needing cutting-edge solutions, the experience has been both rewarding and enlightening. Every new undertaking is an opportunity to apply our knowledge and push the limits of this remarkable machining process.

Exploring EDM Services

When seeking EDM Services Near Me, it’s crucial to comprehend the vast landscape of electrical discharge machining options. Typically, these services span various techniques, including wire EDM, sinker EDM, and hole drilling EDM. Each method serves a specific role, tailored to distinct industrial needs. For instance, wire EDM is perfect for crafting intricate components with extreme precision, while sinker EDM is favored for mold-making and complex cavities in hard materials.

The flexibility and precision offered by EDM make it an invaluable tool for sectors ranging from aerospace to automotive and beyond. Companies like Anco Precision Inc., with their deep expertise in CNC machining, also provide superb electrical discharge machining services, ensuring meticulous attention to detail and quality. This amalgamation of traditional machining with EDM techniques ensures that all aspects of a project are executed with unmatched precision.

Tailoring Solutions to Industries

EDM Services Near Me caters to a myriad of industries, each with unique requirements and challenges. For instance, the medical field often demands components with micro-level precision, something EDM can deliver effortlessly. Aerospace applications, on the other hand, focus on durability and exact alignment, where EDM’s precision cutting plays a pivotal role.

Understanding these industry-specific demands allows service providers like Anco Precision to customize their approach. The expertise in handling diverse materials–from metals to specialized alloys–enables the delivery of components that meet stringent quality standards. In automotive and marine sectors, rapid prototyping via EDM can significantly reduce time to market, enhancing competitive advantage.

Manufacturers specializing in EDM Services Near Me are also adept at offering a consultative approach, advising clients on optimum methods and materials to use for their specific projects. This tailored guidance not only improves output quality but also optimizes cost efficiency and production timelines.

Personalized Experiences in EDM

Working with EDM Services Near Me involves more than just technical precision; it’s about building relationships and trust. The close-knit team at Anco Precision brings not only technical prowess but also a personal touch to the machining process. For example, clients have shared how proactive communication and quick adaptation to changing needs resulted in successful project outcomes, highlighting the human element in precision machining.

Collaboration is key, and Anco Precision exemplifies this by welcoming feedback and being flexible in operations. This ensures that each client’s vision is realized to its fullest potential. The combination of advanced technology and personal engagement fosters a productive environment, essential for tackling complex machinist challenges.

For businesses and individuals seeking reliable partners in machining, the availability of EDM Services Near Me brings a sense of assurance and convenience. The ability to discuss intricate project details in person and see firsthand the capabilities of state-of-the-art equipment makes a significant difference in choosing the right service provider.

- Customization in design and execution.

- Expert guidance on material and method selection.

- Continuity of service through personal engagement.

Understanding EDM Machining

How does Electrical Discharge Machining (EDM) differ from traditional machining methods?

EDM is a non-contact thermal process that uses electrical discharges to remove material from a workpiece. Unlike traditional machining, which involves direct contact, EDM is highly effective for hard materials like steel and titanium. This is essential for industries requiring high precision, such as aerospace and medical. At Anco Precision Inc., we’ve used EDM to achieve intricate designs with unmatched accuracy, something traditional methods often struggle with.

What are the different types of EDM Machining, and what applications are they best suited for?

There are three primary types: Die-Sinking (or Ram) EDM, Wire EDM, and Hole-Drilling EDM. Die-Sinking is ideal for creating complex molds and cavities, Wire EDM excels in cutting intricate parts with high precision, and Hole-Drilling EDM is perfect for creating small, precise holes. At Anco Precision, we’ve leveraged each type to cater to specific project needs, such as crafting precise components for marine and medical industries.

What are some common challenges faced in EDM Machining?

One major challenge is the energy consumption and time required, especially for large batches like automotive parts. Another is the technical expertise needed to operate EDM equipment effectively. At Anco Precision, continual training ensures our machinists are equipped to handle these challenges, maintaining quality and precision in our output.

EDM Wire Cutting Insights

What makes EDM Wire Cutting stand out in CNC machining?

EDM Wire Cutting uses a thin wire to erode material with high precision, making it invaluable for producing intricate parts with minimal material waste. This is particularly beneficial in aerospace, automotive, and medical fields. At Anco Precision, we pride ourselves on using wire cutting to deliver parts that meet tight tolerances while optimizing material use, thereby supporting sustainable practices.

How does EDM Wire Cutting benefit industries like aerospace and medical?

The precision and ability to cut hard materials without altering their properties make EDM Wire Cutting highly advantageous. For aerospace, it ensures exact component alignment, while in the medical field, it delivers micro-level precision necessary for devices. These capabilities give Anco Precision a competitive edge when crafting components that require exceptional accuracy and performance.

Exploring Local EDM Services

What should I consider when selecting EDM services near me?

When looking for EDM services nearby, consider the provider’s expertise, equipment, and their ability to tailor solutions to your industry needs. Providers like Anco Precision offer consultation on the best methods and materials to use, ensuring that each project is executed with precision and efficiency. Their experience in diverse fields, from automotive to aerospace, means they’re adept at meeting various specifications.

How can local EDM services enhance project timelines and quality?

Working with a local service can streamline communication and shorten lead times, which is crucial for time-sensitive projects. At Anco Precision, our team’s ability to adapt quickly to project changes and communicate effectively with clients has consistently resulted in successful outcomes. This collaboration not only enhances quality but also fosters trust and reliability in our services.

Advanced EDM Machining Insights

What are some misconceptions about EDM Machining?

A common misconception is that EDM is slow and inefficient. While it may take longer than some traditional methods, the precision and capability to machine complex parts without damaging the material outweigh the time factor. At Anco Precision, we’ve demonstrated that the end quality and durability of EDM components justify the investment in time and resources.

How is technology shaping the future of EDM Machining?

Advancements in EDM technology, such as automation and AI integration, are enhancing precision and reducing production times. These technologies allow for greater complexity in designs and improved efficiency. At Anco Precision, we continuously incorporate these advancements to stay ahead in the industry and ensure our clients receive the most innovative solutions.

Resources

- NASA – Official website of the National Aeronautics and Space Administration, providing valuable information on aerospace technology and innovation.

- National Institutes of Health (NIH) – The NIH is a leading source of medical research and information, offering insights into the medical industry’s demands for precision machining.

- National Institute of Standards and Technology (NIST) – NIST sets standards for various industries, including manufacturing, where precision machining techniques like EDM are crucial.

- American Society of Mechanical Engineers (ASME) – ASME provides resources and guidelines for mechanical engineers, including information on advanced machining technologies.

- Engineering Toolbox – A comprehensive resource for engineers, offering tools and information on various engineering topics, including machining processes.