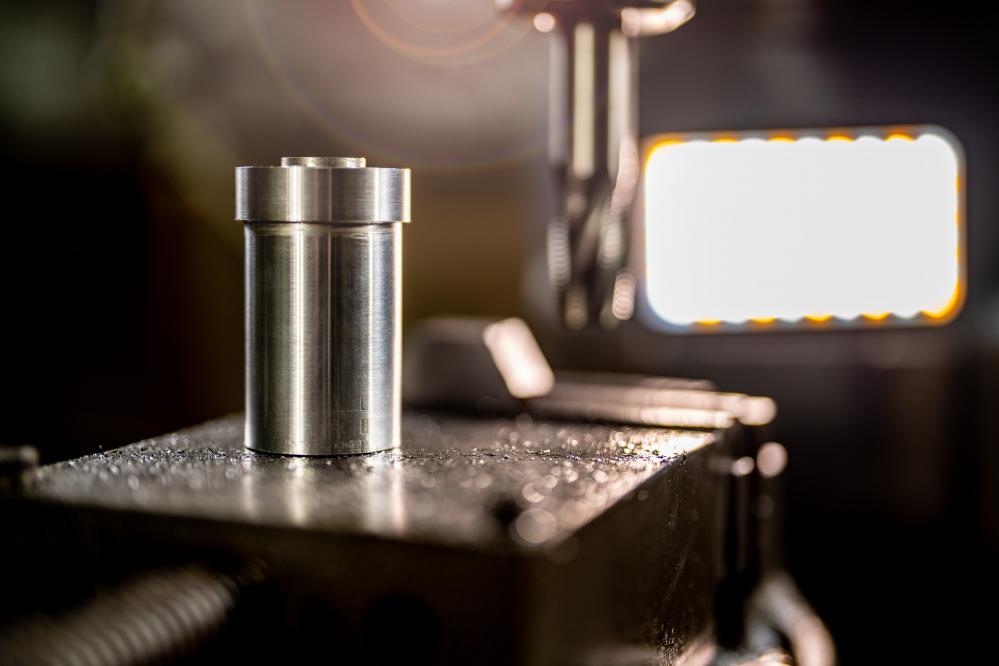

The Importance of Custom Machining

At our core, we understand the pivotal role that custom machining plays in the modern world. It’s the backbone of innovation across industries, turning abstract ideas into tangible solutions that drive progress. From aerospace to medical devices, the demand for precisely machined parts is unending. Our dedication to this craft stems from a commitment to quality and a passion for meeting the complex needs of our clients with unparalleled accuracy.

Our Services and Capabilities

In the realm of custom machining, versatility and precision are key. We pride ourselves on our ability to offer a wide range of services, including CNC milling, CNC turning, rapid prototyping, and screw machining. This versatility allows us to accommodate projects of various sizes and complexities, ensuring that every part we produce meets the highest standards of precision and quality.

Specialized Projects and Industries Served

Our expertise in custom machining is not limited to a single industry. Over the years, we’ve had the privilege of serving clients from aerospace, automotive, marine, and medical fields. Each project brings its own set of challenges and requirements, pushing us to continually hone our skills and expand our capabilities. It’s through this diversity of experience that we’ve grown to become a trusted partner for innovative solutions in custom machining.

Client Testimonials and Experiences

Feedback from our clients is a testament to our commitment to excellence. We’ve been described as not just a service provider, but a partner in innovation. Clients appreciate our attention to detail, quick deliveries, competitive pricing, and, most importantly, our consistency in quality. These testimonials are not just words of praise but a reflection of the trust and reliability we strive to build with every project.

Building Lasting Relationships

Our approach to custom machining goes beyond just manufacturing parts. We aim to build lasting relationships with our clients, understanding their needs and challenges as if they were our own. This client-centric mindset has been central to our success, fostering collaboration and ensuring that we always deliver solutions that truly meet our clients’ needs.

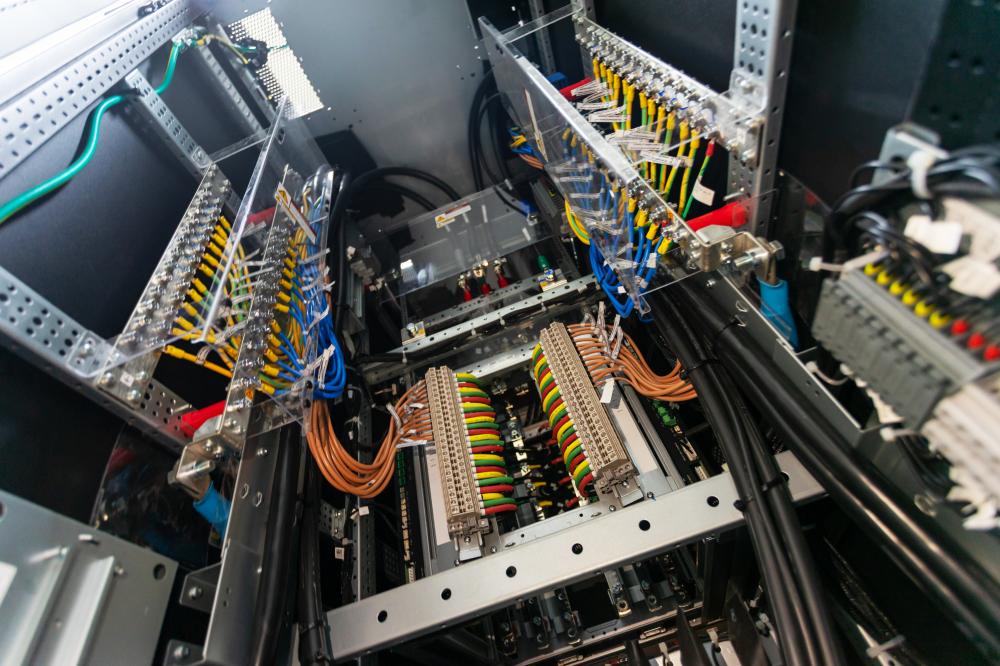

Innovation and Continuous Improvement

In the ever-evolving field of custom machining, staying ahead means being committed to continuous improvement. We invest in the latest technologies and training for our machinists, ensuring that we’re not just keeping up with the industry standards but setting them. Our in-house capabilities allow us to take on projects that others might find too challenging, pushing the boundaries of what’s possible in custom machining.

Why Choose Us for Your Custom Machining Needs

Choosing a custom machining partner is a decision that can significantly impact the success of your project. At Anco Precision Inc., we offer not just services, but solutions tailored to your specific needs. With our extensive experience, state-of-the-art equipment, and dedication to quality, we’re equipped to handle projects of any complexity. Whether you need a prototype or production parts, we’re here to ensure your project’s success.

Instant Quotes and Quick Turnaround

Understanding the importance of time in project development, we offer instant quotes through our online machine shop. This streamlined process ensures that you can quickly get your project off the ground without unnecessary delays. Our commitment to quick turnaround times, without compromising on quality, sets us apart in the custom machining industry.

Conclusion

Custom machining is more than just a service we offer; it’s a passion that drives us to excel. At Anco Precision Inc., we’re committed to delivering the highest quality machining solutions, tailored to the specific needs of our clients. With over 40 years of experience, a dedication to innovation, and a focus on building lasting relationships, we’re not just a machining shop; we’re a partner in your project’s success. Let us bring our expertise to your next project and experience the difference that precision and passion can make.

What is custom machining and why is it essential?

Custom machining is essentially the process of designing and manufacturing specific components that meet unique specifications and requirements. At Anco Precision Inc., we believe it plays a crucial role in innovation across various industries. Imagine needing a part for a vintage car or a specialized medical device; off-the-shelf options may not suffice. Custom machining steps in to fill this gap, turning unique designs into reality, ensuring that industries can continue to push the boundaries of what’s possible, be it in aerospace, automotive, or healthcare. It’s not just about making parts; it’s about bringing visions to life with precision and quality.

How do you ensure quality in custom machining?

Quality in custom machining is non-negotiable. At Anco Precision Inc., our dedication to manufacturing products at 100% precision underpins our operations. This commitment starts from the moment we review a client’s specifications to the final quality check before delivery. Our machinists are extensively trained and utilize state-of-the-art equipment to maintain high standards. Moreover, we engage in continuous improvement, investing in the latest technologies and training to not just meet but exceed industry standards. Imagine crafting a component that forms the heart of a groundbreaking medical device; its flawless execution could be life-saving. That’s the level of quality we aim for every single project.

What sets your services apart in the custom machining industry?

What truly sets Anco Precision Inc. apart is our holistic approach. We’re not just a machine shop; we see ourselves as your partner in innovation. This partnership perspective means we dive deep into understanding your needs and challenges as if they were our own. Combine this with our over 40 years of experience, state-of-the-art equipment, and a team passionate about precision, and you get a service tailored to your specific needs. Our capability to offer instant quotes and ensure quick turnaround times, without compromising on quality, further distinguishes us. It’s like having a trusted friend in the industry who’s ready to jump hurdles with you, ensuring your project’s success.

Can custom machining be cost-effective for small businesses or startups?

Yes, absolutely. Custom machining is often perceived as expensive, primarily suited for large enterprises. However, at Anco Precision Inc., we’ve tailored our services to be inclusive, offering competitive pricing and scalability that can accommodate the dynamic needs of small businesses and startups. The key is in our efficiency and the ability to provide rapid prototyping that can significantly reduce the time and cost of developing new products. Imagine a startup aiming to launch an innovative product; our custom machining services can accelerate their market entry while controlling costs, turning potential barriers into pathways for growth and innovation.

How does custom machining support innovation in various industries?

Custom machining is the silent engine driving innovation in numerous fields. By providing the capability to create precise and bespoke components, it allows industries to venture into new territories. For instance, in the aerospace industry, the ability to machine parts that meet stringent standards can lead to the development of safer, more efficient aircraft. Similarly, in healthcare, custom machined parts are critical for the evolution of medical devices that can save lives or improve patient care. At Anco Precision Inc., we’ve seen firsthand how our work supports not just the operational goals of our clients but also their ambitions to innovate and redefine what’s possible in their domains.

What is your approach to client relationships and project management?

At Anco Precision Inc., we believe in building lasting relationships with our clients. This means understanding their projects as deeply as they do and managing each project with utmost care and precision. Our approach is hands-on, involving regular communication, transparent processes, and a flexible attitude to adapt to changing requirements. Every client, regardless of the project size, is given personalized attention. This nurturing of relationships not only ensures successful project outcomes but also builds a foundation of trust and collaboration, making every project a smooth and enjoyable journey.

Resources

- Aerospace Manufacturing and Design – Explore the latest news and trends in the aerospace industry.

- Society of Automotive Engineers (SAE) – Access resources and information on automotive engineering.

- Marine Technology News – Stay informed about the latest developments in marine technology.

- American Heart Association Journals – Discover research and articles related to medical devices and healthcare.