The Principles of Contract Manufacturing

Contract Manufacturing involves a collaboration where one company produces goods on behalf of another. This partnership allows the hiring firm to outsource production, benefiting from the manufacturer’s expertise and resources. At Anco Precision, we have seen firsthand how this approach can reduce costs and increase efficiency in production, enabling companies to focus on innovation and sales.

For Anco Precision, specializing in CNC machining services, Contract Manufacturing is integral to our operations. We work closely with clients across various sectors, including marine, automotive, and aerospace, providing tailored manufacturing solutions. This allows organizations to gain access to high-quality products without the need for extensive investments in infrastructure or specialized skills.

Industries benefit from Contract Manufacturing as it allows them to maintain flexibility and adapt swiftly to market changes. By leveraging our expert capabilities, companies can enhance their product offerings and meet customer demands more effectively.

Key Advantages and Challenges of Contract Manufacturing

- Cost Efficiency: The hiring firm can save significantly on capital costs, avoiding the need for purchasing equipment or maintaining production facilities. This cost-saving aspect is particularly appealing in competitive markets.

- Access to Expertise: Anco Precision’s skilled machinists operate state-of-the-art equipment, providing clients with advanced manufacturing solutions they may not possess internally.

- Quality Assurance: Working with experienced manufacturers like Anco Precision ensures stringent quality control, vital for maintaining a brand’s reputation and customer satisfaction.

Despite these advantages, some challenges remain. Issues such as intellectual property risks and potential dependency on the manufacturer highlight the need for careful contract negotiations and continual relationship management.

Application of Contract Manufacturing in Various Industries

Across the diverse sectors served by Anco Precision, Contract Manufacturing is a key strategic component. In the medical industry, for example, precise manufacturing ensures that components meet stringent regulatory standards. Similarly, in aerospace, where precision is critical, our CNC machining services ensure products adhere to exact specifications, reflecting the trust companies place in our capabilities.

In the automotive sector, Contract Manufacturing offers scalable solutions, allowing companies to ramp up production in response to market demands. Anco Precision assists in producing everything from custom car parts to complex engines, illustrating the flexibility inherent in this business model.

Contract Manufacturing plays a crucial role in supporting innovation within the electronics sector. By handling the production of intricate components, manufacturers enable tech companies to focus on research and development, driving industry advancements.

Personal Experiences and Insights from Anco Precision

At Anco Precision, we understand that the success of Contract Manufacturing relies heavily on strong partnerships and clear communication. From our experience, fostering a collaborative atmosphere ensures that both parties benefit and can adapt to evolving needs. During one memorable project, a client’s urgent requirement led to a compressed timeline. By leveraging our efficient processes and teamwork, we met the deadline, reinforcing the trust and reliability expected in such partnerships.

Our expertise in Contract Manufacturing has also highlighted the importance of maintaining cutting-edge technology. As the industry evolves, we continually invest in advanced machinery, ensuring we deliver competitive and high-quality solutions to our clients. This commitment to excellence positions Anco Precision as a leader in the machining industry, consistently meeting the diverse manufacturing needs of our customers.

Ultimately, the insights gained through decades of experience emphasize the transformative potential of Contract Manufacturing. By aligning with the right partners and focusing on core strengths, companies can unlock new opportunities and achieve sustainable growth.

Advantages of Contract Manufacturing Services

Cost Efficiency and Resource Management

Contract Manufacturing Services can significantly reduce production costs for companies, allowing them to allocate resources more effectively. Through strategic partnerships with expert manufacturers like Anco Precision Inc., businesses can cut down on the need for expensive machinery and labor, while benefiting from economies of scale.

Anco Precision Inc. offers CNC machining services that are both cost-effective and high-precision, making it an attractive option for companies across various industries. This partnership not only lowers overhead costs but also enhances production quality through the use of advanced technology.

Access to Expertise and Advanced Technology

When engaging with Contract Manufacturing Services, companies gain access to specialized expertise and state-of-the-art technology. Anco Precision’s team, for instance, is highly trained in operating CNC machines, ensuring that every product meets rigorous standards.

This expertise allows businesses to focus on their core competencies, such as innovation and market development, while the manufacturing partner handles the technical aspects of production. The result is a streamlined production process that supports business growth without compromising on quality.

Applications of Contract Manufacturing Services

Diverse Industry Applications

Contract Manufacturing Services are utilized by a wide array of industries, ranging from aerospace and automotive to medical and consumer electronics. Anco Precision Inc. serves clients in these sectors by providing tailored machining solutions that meet specific industry requirements.

Whether it’s producing aerospace components or medical instruments, contract manufacturers use their expertise to cater to unique industry demands. Anco Precision’s capability to handle diverse projects showcases the versatility of these services, making them indispensable in today’s competitive market.

Rapid Prototyping and Development

For businesses looking to innovate and bring new products to market quickly, Contract Manufacturing Services offer an excellent avenue for rapid prototyping. By collaborating with skilled partners like Anco Precision Inc., companies can accelerate the development phase, gaining a competitive edge.

This capability is particularly beneficial for startups and small businesses that may lack the resources to establish a full-scale production facility. Such partnerships provide the agility needed to adapt swiftly to changing market needs.

Key Considerations in Choosing Contract Manufacturing Services

Evaluating Technical Capabilities

One of the most critical factors when selecting a contract manufacturer is evaluating their technical capabilities and industry experience. Anco Precision Inc.’s decades-long presence in the industry and their expertise in CNC machining make them a preferred choice for many businesses.

Companies should assess potential partners by examining their track record, available technologies, and the scale of their operations to ensure they align with the project’s requirements. A well-matched partner can substantially enhance the overall production process and outcome.

Ensuring Quality Assurance and IP Protection

Quality assurance and intellectual property protection are crucial when working with Contract Manufacturing Services. Reliable manufacturers like Anco Precision prioritize rigorous quality checks, ensuring that products meet required standards.

Additionally, safeguarding intellectual property through robust legal agreements and selecting partners with a reputation for confidentiality are essential steps in mitigating risks. Anco Precision’s commitment to customer satisfaction underscores the importance of trust and transparency in these partnerships.

Precision and Excellence in Contract Manufacturing

The vibrant landscape of Contract Manufacturing Florida is one rich in diversity and expertise. As someone who has collaborated closely with Anco Precision Inc., a family-owned CNC machine shop with over 40 years of experience, I have witnessed firsthand the meticulous precision and unparalleled quality required in this industry. Operating out of Deerfield Beach, Anco Precision stands out, not just for its cutting-edge CNC machining capabilities but also for its commitment to customer satisfaction. This dedication resonates with their clients, who often praise their professionalism, prompt service, and competitive pricing.

It’s no wonder that Florida is a flourishing hub for contract manufacturing. The state hosts a multitude of firms that cater to various sectors, from aerospace and automotive to medical and marine. Each company, like Anco Precision, strives to meet the distinct and stringent requirements of their respective industries. This commitment ensures that they deliver products that not only meet but exceed customer expectations.

Cutting-Edge Technology and Diverse Services

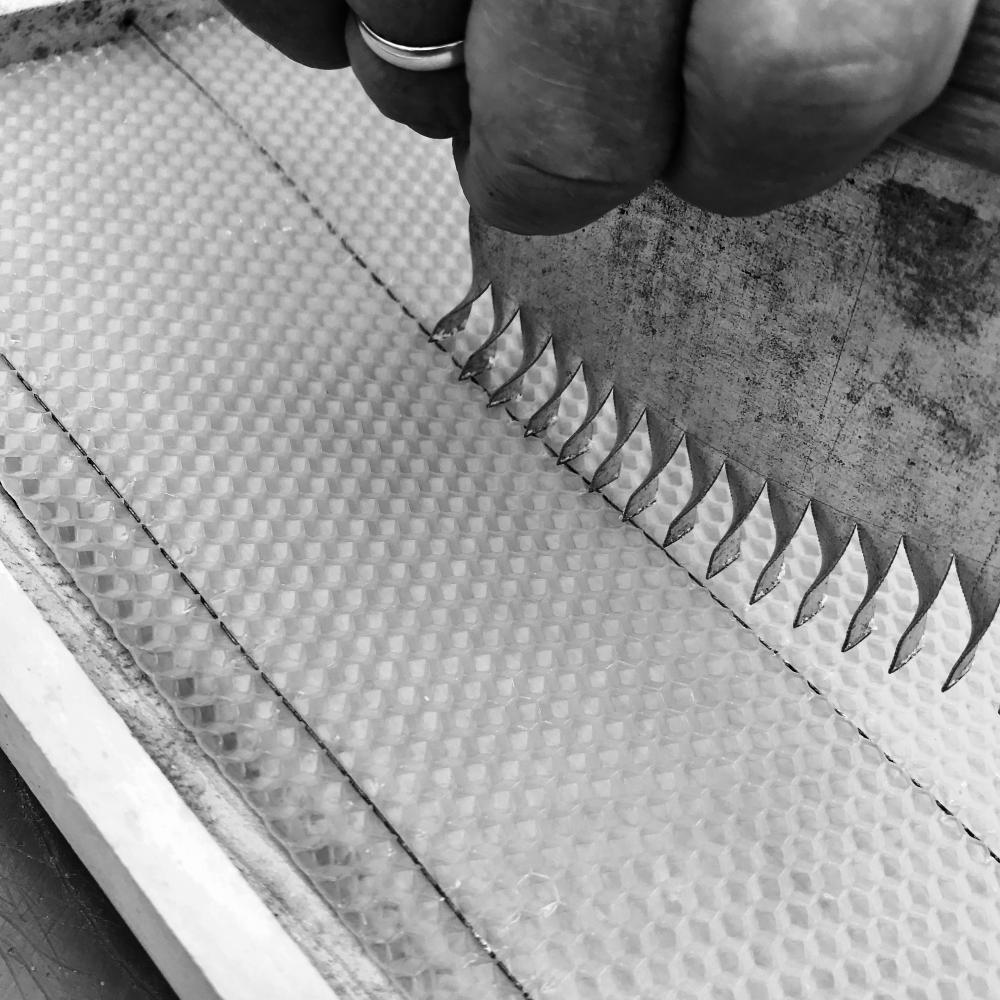

In Contract Manufacturing Florida, variety is more than a hallmark–it’s a necessity. Firms like Anco Precision employ state-of-the-art CNC milling and turning equipment to deliver precision parts for a wide array of applications. Their services include rapid prototyping and screw machining, which are vital for developing custom parts like enclosures, auto engines, and medical instruments. They cater to an extensive client base, including government entities and educational institutions. This diversity in clientele underscores the versatile nature of contract manufacturing in Florida.

From personal experience, the ability to submit a drawing file and receive an immediate quote is an invaluable feature that many manufacturers offer. It streamlines the production process, helping clients move from concept to execution swiftly. Anco Precision, in particular, shines in this area, ensuring that their services remain accessible and efficient for all types of projects. Their skilled machinists are adept at harnessing the latest technology to bring intricate designs to fruition.

Meanwhile, the Florida contract manufacturing sector is underpinned by a commitment to innovation and continuous improvement. Companies constantly seek to refine their techniques and processes, ensuring they remain at the forefront of technological advancements. This focus on progress fosters an environment where quality and performance are paramount.

The Human Touch in Contract Manufacturing

One of the less highlighted aspects of Contract Manufacturing Florida is the human element. While technology and precision are cornerstones of the industry, it’s the personal relationships and trust built over time that truly enhance the business. At Anco Precision, the team fosters a welcoming atmosphere, which is essential when developing long-term partnerships. Their clients often commend the reliability and attentiveness they receive, indicative of the family-run ethos that permeates the company.

As someone who has engaged with Anco Precision, the mutual understanding between client and manufacturer cannot be overstated. This relationship, often built on years of collaboration, allows for a seamless transition between design and production, reducing potential errors and ensuring that the finished product aligns perfectly with initial expectations. Such a dynamic is a testament to the significant role that human interaction plays in the manufacturing process.

In a world that increasingly values automation and efficiency, the personal touch within the industry holds profound importance. Whether you’re a product designer, scientist, or mechanic, knowing that there is a skilled team ready to translate your vision into reality makes a significant difference. This balance of cutting-edge technology with personal expertise is what makes Contract Manufacturing Florida a leader in the field.

Understanding the Benefits and Drawbacks of Contract Manufacturing

When considering contract manufacturing, companies often weigh the benefits against the potential drawbacks. From my experience at Anco Precision, the advantages include cost efficiency, access to advanced technology, and scalability, which can help businesses focus on core competencies such as innovation and marketing. However, challenges like intellectual property concerns and quality control issues can arise. For instance, during my time at Anco, a client was initially worried about maintaining quality standards, but with clear communication and rigorous quality checks, we alleviated their concerns. These situations demonstrate the importance of choosing the right partner who prioritizes transparency and trust. What additional considerations do you think companies should keep in mind when selecting a contract manufacturer?

Applications and Flexibility of Contract Manufacturing Services

Contract manufacturing services offer remarkable flexibility, adapting to the unique demands of varied industries. For example, at Anco Precision, we serve sectors from automotive to medical, each with distinct needs. Our CNC machining capabilities allow us to provide precise, customized solutions quickly. A memorable project involved creating bespoke medical components that required exceptional precision. These experiences highlight how contract manufacturing can drive innovation by allowing companies to quickly prototype and refine their ideas. How do you see contract manufacturing impacting innovation in other fields?

How to Choose the Right Contract Manufacturer in Florida

Selecting a contract manufacturer in Florida involves evaluating their technical expertise, industry reputation, and customer service. At Anco Precision, we emphasize our proven track record and dedication to quality assurance. A potential client might first review feedback from past customers or request a portfolio of previous projects. During a visit, they could observe our state-of-the-art CNC machinery and discuss their specific needs with our team. For instance, a client involved in aerospace was impressed by our commitment to precision and reliability, crucial factors in their decision-making. What factors do you think are most important when building trust with a manufacturing partner?

The Role of Technology in Contract Manufacturing Success

Technology plays a pivotal role in the success of contract manufacturing. At Anco Precision, investing in cutting-edge CNC machinery has allowed us to deliver products with unparalleled accuracy. This investment reflects our commitment to staying ahead of industry advancements. In one instance, the adoption of new technology enabled us to significantly reduce production time for a client’s automotive components, considerably enhancing their market competitiveness. Such improvements underscore the importance of ongoing technological updates in maintaining a competitive edge. How do you think technology influences the relationship between manufacturers and their clients?

Navigating the Human Element in Contract Manufacturing

While technology is critical, the human element in contract manufacturing is equally vital. At Anco Precision, our team’s ability to foster strong client relationships ensures project success. This was evident in a project where early-stage collaboration and constant communication led to the successful delivery of complex aerospace components. Balancing technological prowess with personal interaction allows us to cater to client needs more effectively. I’ve found that understanding the client’s vision and maintaining open dialogue often leads to the most successful outcomes. In your opinion, what role does communication play in manufacturing partnerships, and how can it be improved?

Resources

- Food and Drug Administration (FDA) – The FDA is responsible for protecting the public health by ensuring the safety, efficacy, and security of human and veterinary drugs, biological products, and medical devices.

- National Aeronautics and Space Administration (NASA) – NASA is responsible for the nation’s civilian space program and for aeronautics and aerospace research.

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory federal agency that promotes innovation and industrial competitiveness by advancing measurement science, standards, and technology.

- National Institutes of Health (NIH) – The NIH is the primary agency of the United States government responsible for biomedical and public health research.

- American Society of Mechanical Engineers (ASME) – ASME is a professional association that promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe.