Precision in CNC Services

At Anco Precision Inc., our commitment to accuracy defines our approach to CNC Services. Each machined part is produced with meticulous attention to detail, a trait honed over four decades of experience. This dedication to precision ensures that no matter how complex the task, whether crafting custom car parts or medical instruments, we achieve unparalleled results.

Our machinists are continuously trained to operate state-of-the-art CNC equipment, which allows us to maintain the highest standards in the industry. This training empowers our team to execute projects with tight deadlines, ensuring reliability and satisfaction for clients across multiple sectors including marine, aerospace, and automotive industries.

Client testimonials frequently highlight the precision of our CNC Services. Our ability to maintain stringent quality standards while delivering on time and within budget is a testament to our finely-tuned processes and the expertise of our team. Partnering with Anco Precision means partnering with excellence.

Diverse Applications of CNC Services

One of the strengths of our CNC Services is their broad applicability. We cater to a diverse range of industries, providing solutions for aerospace companies, government agencies, and more. This breadth is supported by our capabilities in CNC milling, CNC turning, rapid prototyping, and screw machining, enabling us to tackle projects of varied scope and complexity.

In the automotive sector, for instance, custom engine components and enclosures are a regular part of our workload. Similarly, in the medical field, we craft precise instruments and devices that meet rigorous industry standards. Anco Precision also supports creative endeavors, equipping product designers and inventors with the tools to bring their visions to life.

Our online platform simplifies the process of acquiring CNC Services. By submitting a drawing file, clients can receive instant, detailed quotes, allowing projects to commence without delay. This efficiency is crucial in today’s fast-paced market.

Innovations and Efficiencies in CNC Services

Innovation is at the core of our CNC Services, driven by the needs of our clients and the evolution of technology. We integrate cutting-edge techniques and processes to enhance our machining capabilities, ensuring that we remain at the forefront of the industry. This drive for innovation leads us to continually refine our methods, reducing lead times and delivering superior results.

A significant advancement in our operations is the adoption of rapid prototyping techniques. This approach not only expedites the development of prototypes but also allows for iterative improvements, crucial for sectors that demand precision in prototypes and production parts alike.

Furthermore, our commitment to competitive pricing without compromising quality is a testament to our efficient operations. By optimizing every stage of the manufacturing process, we deliver cost-effective CNC Services that are accessible to businesses of all sizes, from small startups to large corporations.

Understanding the unique needs of each client is vital in our approach. By aligning our expert resources with client goals, we provide CNC Services that are not only precise but also innovative and efficient.

Advantages of Choosing Anco for CNC Services

Choosing Anco Precision for CNC Services offers numerous benefits, primarily rooted in our extensive industry experience and craftsmanship. We deliver exceptional quality products that consistently meet client specifications, backed by our ISO-certified processes. This assurance of quality makes us a preferred choice for industries with stringent standards, like aerospace and medical sectors.

Our facility in Deerfield Beach, FL, is equipped with advanced technology to handle a wide array of CNC machining tasks. This enables us to offer services that are both versatile and capable of addressing unique challenges, whether it’s creating components for cutting-edge technologies or manufacturing precision parts for everyday products.

Finally, our dedication to customer service sets us apart. From the initial inquiry to the final delivery, our team is committed to ensuring a smooth and satisfactory experience for all our clients. This client-focused approach, combined with our technical expertise, positions Anco Precision as a leader in CNC Services.

The Importance of High-Precision Services

In the realm of CNC Services Florida, precision is not just a requirement but an art form. At Anco Precision Inc., we have been mastering this art for over 40 years, delivering unmatched precision in every project we undertake. Whether the project involves manufacturing custom car parts or intricate aerospace components, the demand for exacting standards is paramount. Working with a team that values meticulous attention to detail, like ours, ensures that components align perfectly, reducing errors and improving efficiency in the final product.

Precision in machining is crucial for industries that rely on high-performance outputs. The medical sector, for example, benefits significantly from our expertise in producing devices that meet stringent health and safety regulations. By leveraging state-of-the-art equipment and a team of highly trained machinists, we are able to satisfy the diverse needs of our clients, maintaining the highest standards in the field of CNC Services Florida.

A Broad Spectrum of Services

When exploring CNC Services Florida, one must acknowledge the extensive array of services offered by Anco Precision Inc. Our offerings range from CNC milling and turning to rapid prototyping and screw machining. This versatility allows us to cater to a wide array of industries, from automotive and marine to electronics and beyond. Each service we provide is tailored to fit the specific requirements of our clients, ensuring that every project is handled with the utmost care and expertise.

Our rapid prototyping capabilities enable customers to visualize their designs quickly and efficiently, providing a crucial step in the product development process. By utilizing cutting-edge technology, we streamline the transition from design to finished product, offering a seamless experience for our clients. This flexibility in services is a testament to our commitment to being a one-stop shop for CNC Services Florida.

The attention to quality throughout our diverse services has garnered Anco Precision a reputation for reliability and excellence. Our clientele spans from government agencies to individual inventors, showcasing the wide-reaching applicability of our machining solutions. By offering such a broad spectrum of services, we maintain our position as leaders in the CNC industry.

Insights from Customer Experiences

A significant part of what makes CNC Services Florida exceptional is the customer experience we provide at Anco Precision Inc. Clients frequently highlight the professionalism and swift turnaround times they experience when working with us. One client, an aerospace engineer, praised the team’s ability to meet challenging deadlines without sacrificing quality. This dedication to service excellence ensures that every partnership we form is built on trust and mutual respect.

Our instant quotes service exemplifies our commitment to efficiency and customer satisfaction. By allowing customers to submit drawings for immediate detailed quotes, we facilitate a smoother start to their projects. This streamlined process not only saves time but also empowers clients with the information they need to make informed decisions swiftly.

In addition to our technical prowess, the human element of our service cannot be overstated. As a family-owned business, Anco Precision Inc. fosters a relationship-driven approach, where the needs and expectations of each client are prioritized. This personal touch adds an invaluable layer of trust and communication, ensuring that every aspect of our CNC Services Florida meets and often exceeds client expectations.

Our open-door policy invites clients to visit our facility, giving them the opportunity to witness firsthand the precision and care that goes into each project. By offering this transparency, we build lasting relationships grounded in trust and shared success, making our services not only a transaction but a collaborative journey.

What is Aluminum CNC Service?

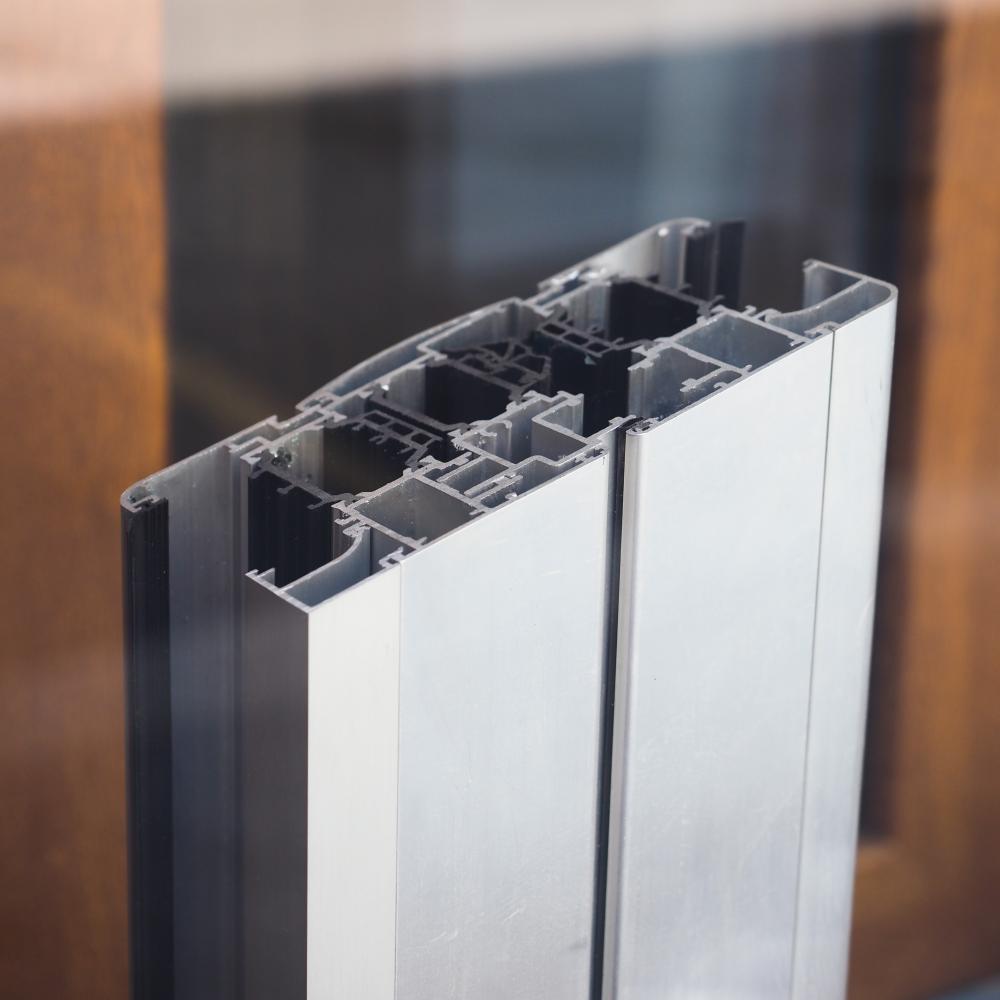

Aluminum CNC Service is a specialized manufacturing process that utilizes computer numerical control to shape aluminum alloys into various parts and components. This precision-driven method is a cornerstone of modern manufacturing, with its applications spanning multiple industries ranging from aerospace to consumer electronics. At Anco Precision Inc., located in Deerfield Beach, FL, we bring over 40 years of industry expertise to the table, ensuring each project is executed with meticulous attention to detail and unwavering quality.

Our customers often marvel at the versatility of aluminum CNC machining. Aluminum’s unique strength-to-weight ratio makes it the material of choice for projects that require durability without the heft. From creating intricate marine components to robust automotive parts, our Aluminum CNC Service is adept at accommodating diverse production needs. The processes we employ, including CNC milling and turning, enable us to achieve the high tolerances necessary for today’s demanding product applications.

Benefits of Aluminum CNC Service

Precision and Quality

When it comes to producing aluminum parts, precision is paramount. At Anco Precision, we pride ourselves on our commitment to delivering 100% precision for every product we manufacture. Our machinists are extensively trained to operate cutting-edge equipment, allowing us to deliver not only precision but also consistent quality. For those requiring rapid prototyping, our Aluminum CNC Service provides quick turnaround times without sacrificing accuracy, garnering trust and satisfaction from our clients.

Diverse Applications

Aluminum CNC Service is not a one-size-fits-all solution. The versatility of aluminum alloys makes them suitable for a wide range of applications. Whether clients need custom car parts, medical instruments, or aerospace components, our CNC machining services can meet these varied requirements. Each project presents its unique challenges, and we take pride in our ability to offer tailored solutions that meet our clients’ precise specifications.

Cost-effectiveness and Innovation

One of the often-overlooked advantages of utilizing Aluminum CNC Service is its cost-effectiveness. Through our online quoting system, we streamline the process, providing instant quotes based on detailed client specifications. This not only saves time but also ensures transparency in pricing, making it easier for businesses to plan their budgets effectively. Our innovative approach to machining also allows us to offer competitive pricing without compromising on quality, an aspect highly appreciated by both returning and new clients alike.

Personal Experiences with Aluminum CNC Service

Reflecting on my own experience with Aluminum CNC Service at Anco Precision, I can attest to the transformative power of cutting-edge technology in manufacturing. I recall working on a project for a major aerospace client where the precision required was daunting. Through collaboration and leveraging our CNC capabilities, we delivered components that not only met but exceeded client expectations. It’s rewarding to be part of a team that consistently pushes the boundaries of what’s possible in manufacturing.

Clients frequently share their satisfaction with our aluminum CNC projects, expressing appreciation for the swift service and exceptional quality they receive. Whether it’s producing a prototype for a startup or fulfilling a complex order for a large corporation, our Aluminum CNC Service ensures we deliver excellence, time and again. Our commitment to customer satisfaction is reflected in the testimonials we receive, solidifying our reputation as a trusted partner in the manufacturing community.

What are the common misconceptions about CNC Services?

One prevalent misconception about CNC Services is that they are prohibitively expensive for smaller businesses. In reality, advancements in technology and streamlined processes, such as those we have at Anco Precision, have made CNC machining more accessible and cost-effective. Additionally, people often think CNC Services are only suitable for large-scale production. However, the precision and customization offered by CNC machining make it ideal for small batch and prototype production as well.

It’s also worth noting that some believe CNC machining is limited to simple parts. On the contrary, the sophistication of CNC equipment allows for the creation of complex and intricate components across various industries, from aerospace to medical devices. Have you considered how CNC machining could address challenges in your current projects?

How do CNC Services enhance precision in manufacturing?

At Anco Precision, CNC Services are central to achieving high accuracy and consistency in manufacturing. The use of computer numerical control ensures that every cut and motion is meticulously calculated and executed, reducing the margin for human error. Our machinists receive extensive training in using state-of-the-art equipment, allowing us to maintain precision across even the most complex tasks.

CNC machining is particularly beneficial when producing components that require tight tolerances, ensuring each part fits perfectly within an assembly. This level of precision minimizes waste and reduces the need for rework, providing a more efficient production process. Consider the impact of precision on your project’s efficiency–how might it improve your final product quality or speed up your production timeline?

What are the key benefits of CNC Services in Florida?

In Florida, CNC Services offer several advantages, particularly with a provider like Anco Precision. The local access to high-quality machining reduces shipping times and costs, providing quicker turnaround for projects. Florida’s diverse industrial landscape means there’s a high demand for CNC Services across sectors such as aerospace, marine, and automotive, each benefiting from the precision and customization CNC provides.

Moreover, the competitive environment in Florida spurs innovation and cost-effectiveness, ensuring that clients receive exceptional value for their investments. Have you tapped into the local expertise available in Florida to enhance your project outcomes?

How does rapid prototyping integrate with CNC Services?

Rapid prototyping through CNC Services at Anco Precision allows for the quick transformation of designs into physical models. This capability enables clients to visualize and test their concepts faster than traditional methods. By using CNC machines for prototyping, modifications can be swiftly implemented, facilitating iterative design improvements.

As an example, in an aerospace project, rapid prototyping can reduce the time from design to testing, enabling faster innovation cycles. This integration ensures that any adjustments are made with high precision, maintaining consistency in the final product. How might shortening your prototype development timeline impact your project goals?

What is Aluminum CNC Service, and why is it important?

Aluminum CNC Service involves using CNC machines to precisely shape aluminum into required components, leveraging its unique properties such as strength-to-weight ratio. It’s crucial for industries where lightweight yet durable parts are necessary, such as in aerospace or automotive.

At Anco Precision, our expertise in aluminum CNC machining ensures that we can produce high-quality parts that meet rigorous industry standards. This service is adaptable for prototypes as well as large-scale production, making it an essential tool for manufacturers. What benefits do you see in using aluminum for your next project?

How does Anco Precision ensure quality in its CNC Services?

Quality is at the heart of Anco Precision’s CNC Services. We adhere to ISO-certified processes that set the benchmark for consistency and excellence. Our machinists undergo regular training to keep up with technological advancements, ensuring they can operate our state-of-the-art CNC equipment with precision.

Moreover, we incorporate rigorous quality control measures at every production stage, from initial design to final inspection. This thorough approach guarantees that every component we produce meets client specifications. How might reliable quality control impact your confidence in output quality?

How can businesses determine the right CNC Service provider?

Choosing the right CNC Service provider involves several considerations, including their expertise, equipment quality, and customer service. At Anco Precision, we recommend evaluating potential providers based on their experience in your specific industry, the range of services offered, and their track record for meeting deadlines and quality standards.

It’s also crucial to consider the technological capabilities and the provider’s commitment to innovation. Engaging with a provider that offers instant quotes and maintains a transparent communication process can signal a seamless experience. In your search, what specific criteria are you prioritizing to ensure the best partnership?

What role does customer experience play in choosing CNC Services?

Customer experience is a crucial factor in selecting CNC Services because it affects communication, project management, and satisfaction. At Anco Precision, we prioritize strong relationships with our clients, ensuring transparency and responsiveness throughout the project lifecycle. This personal approach helps build trust and ensures that projects run smoothly.

Positive testimonials and repeat business often indicate a provider’s reliability and commitment to customer satisfaction. In your experience, how has customer service influenced your project outcomes, and what aspects are most important to you?