The Evolution of Automotive Machining

Automotive Machining has undergone significant transformations since its inception, driven by technological advancements and industry demands. The roots of this evolution trace back to the early 20th century when traditional manual processes were the norm. Fast forward to today, and the landscape has been dramatically reshaped by CNC (Computer Numerical Control) technology, offering precision and repeatability unheard of in previous generations.

The ability of modern CNC machines to handle complex geometrical designs has opened new horizons for auto manufacturers. This technology has become indispensable in producing custom car parts, intricate engine components, and even the most delicate automotive electronics. At Anco Precision Inc., located in Deerfield Beach, FL, the focus is on meeting the diverse needs of industries, showcasing how commitment to advancement keeps businesses ahead of the curve.

Beyond technological enhancements, the shift towards eco-friendly processes is yet another notable development in Automotive Machining. Companies across the globe, including Anco Precision, are adopting sustainable practices by optimizing materials and energy usage without compromising on quality.

Precision and Efficiency in Modern Machining

In today’s competitive automotive sector, precision is paramount, and efficiency is key. Automotive Machining, specifically through CNC technology, embodies these principles by delivering products with exact specifications and minimal errors. Anco Precision exemplifies this with its commitment to 100% precision in every project, whether it involves rapid prototyping or production machining.

The use of CNC milling and turning capabilities ensures that every auto part meets stringent quality standards. This precision not only enhances the performance of automotive components but also ensures they fit perfectly within the larger assembly, reducing time spent on adjustments and reworks. Efficiency further manifests in Anco Precision’s ability to offer quick turnarounds, facilitating faster deliveries to customers eager to hit the road with their innovations.

Diverse Applications and Customer Satisfaction

The versatility of Automotive Machining is evident in its wide-ranging applications, encompassing everything from custom car parts to complex aerospace components. At Anco Precision, this diversity is matched by an equally diverse clientele, including government agencies, universities, and individual inventors. The broad scope of services–encompassing CNC turning, screw machining, and more–means that no project is too niche or too large.

Customer satisfaction is a cornerstone of Anco Precision’s operations. Testimonials frequently highlight the company’s dedication to quality, competitive pricing, and professional service. The family-owned business takes pride in its long-standing relationships with clients, built on trust and consistent delivery of excellently machined parts. The ability to provide instant online quotes further enhances customer experience by simplifying project initiation.

A critical aspect of maintaining customer satisfaction lies in constant communication and feedback loops, ensuring that client expectations are not just met, but exceeded. Anco Precision’s team is always ready to engage, whether it’s refining a design or advising on the best machining approach for a given part.

In summary, the varied applications of Automotive Machining demonstrate the adaptability and innovation within the industry. This versatility, combined with a focus on customer-centric service, underscores the enduring relevance and impact of companies like Anco Precision in the modern machining landscape.

Precision in CNC Machining

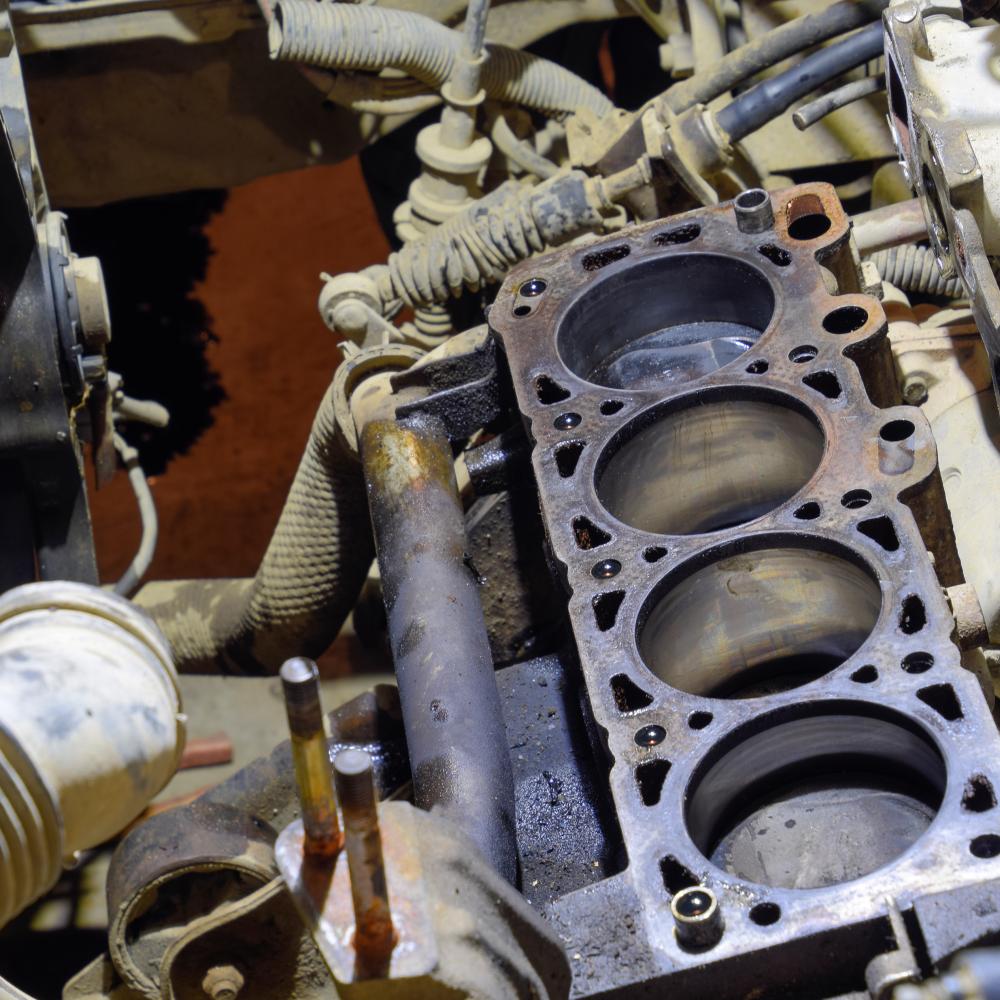

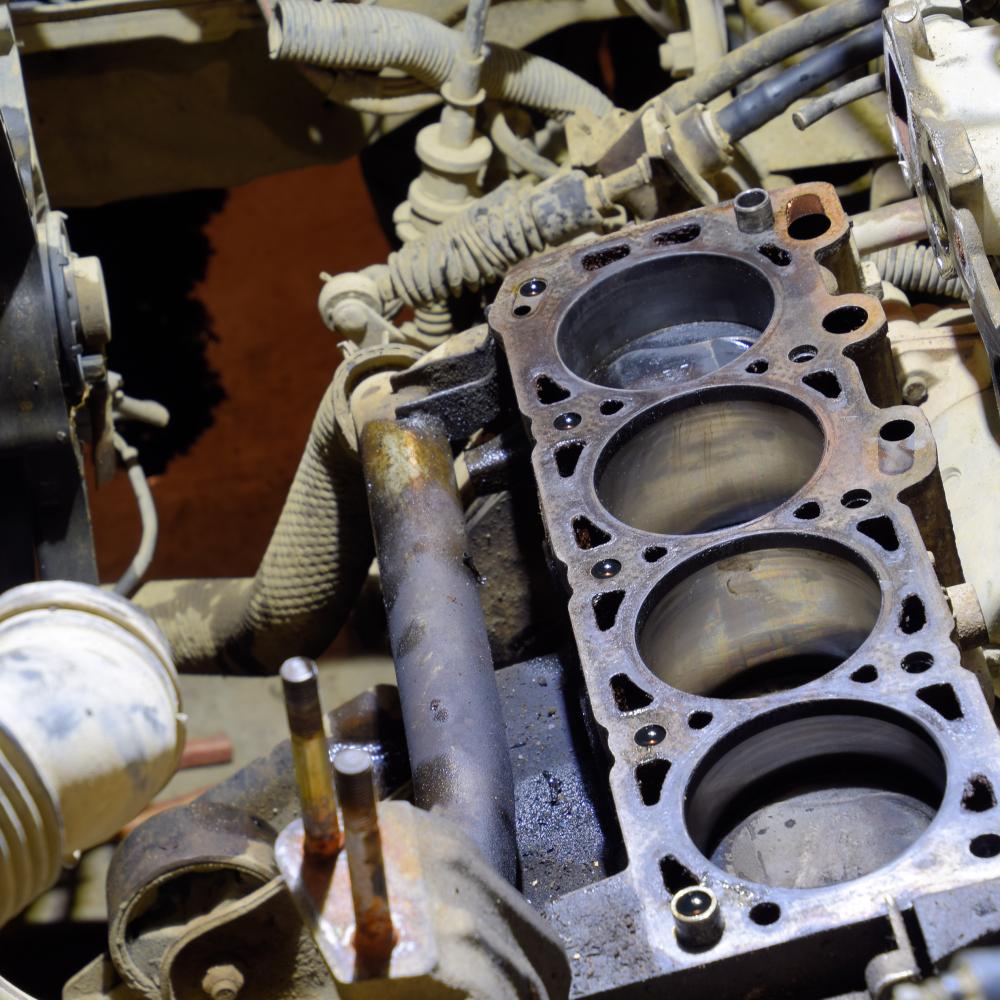

As a trusted name in the world of machining, Anco Precision Inc. exemplifies the art of precision in CNC machining. With over four decades of experience, this family-owned business has been at the forefront of technological advancements in the industry. Specializing in CNC milling and turning, their cutting-edge techniques ensure that every product meets exact specifications. Their capability to produce custom car parts, enclosures, and auto engines with such remarkable accuracy is a testament to their dedication to quality. The machinists at Anco Precision undergo rigorous training to ensure they operate the latest equipment with unparalleled efficiency.

The Automotive Machine Shop services offered by Anco Precision cover a broad spectrum, including rapid prototyping and screw machining. Such diversity in service provision allows them to cater to an array of industries like marine, medical, and aerospace, besides automotive. This wide-ranging expertise is not merely academic; it is reflected in the consistently high standards maintained across all projects, big or small. Clients from various sectors have praised Anco Precision for their unmatched attention to detail and swift turnaround times.

- Custom car parts

- Auto engines

- Enclosures

- Robots and models

Dedication to Customer Satisfaction

At the heart of Anco Precision’s operations is a steadfast commitment to customer satisfaction. Each project is a collaboration between the client and the team, ensuring that specific needs are fully understood and met with careful execution. This collaboration often involves instant quotes available through their online portal, allowing customers to submit drawings and receive detailed assessments almost immediately. This service is particularly beneficial for those in prototype or production part manufacturing, where time efficiency is crucial.

Communication is key, and Anco Precision excels in maintaining transparency throughout the machining process. Clients can rest easy knowing they are kept in the loop from the initial quote to the project’s completion. This approach to customer service not only builds trust but also reinforces Anco Precision’s reputation as a reliable partner in the Automotive Machine Shop landscape.

Anecdotal evidence from long-term clients reveals that Anco Precision is not just a machine shop but a cornerstone in their businesses’ success. Many have lauded the quick delivery times and competitive prices, attributing their satisfaction to the shop’s relentless pursuit of excellence.

Expanding Horizons in the Machining Industry

Innovation is at the core of Anco Precision’s operations. They are constantly adapting to the ever-changing needs of the machining industry, which includes staying abreast of new technologies and methodologies. As a leader in providing Automotive Machine Shop services, Anco Precision is not content with just maintaining industry standards; they are continually pushing boundaries to redefine them. This forward-thinking mindset translates into an expanded suite of services, allowing them to accommodate complex projects across various industries, from aerospace to medical devices.

For businesses and individuals alike, partnering with Anco Precision means accessing a wealth of knowledge and an unwavering dedication to precision. Their commitment to excellence and industry leadership ensures that clients receive not only the highest quality products but also invaluable insights into the world of machining.

- Aerospace innovation

- Medical device precision

- Custom project solutions

In a world where precision and reliability are non-negotiable, Anco Precision stands as a beacon of quality in the Automotive Machine Shop sector. Their relentless drive for perfection makes them an indispensable partner for any machining needs.

Exceptional Precision Services

At Anco Precision Inc., a trusted name in the CNC machining sector, quality and precision are not just promises but practices embedded deep within the company’s ethos. Situated in Deerfield Beach, FL, Anco Precision stands out as a beacon of excellence in the engine machine shop Florida industry. With a rich legacy spanning over four decades, the company provides impeccable services to industries as diverse as marine, automotive, and aerospace.

The team at Anco Precision prides itself on the meticulous training undergone by its machinists, ensuring each product is manufactured with 100% precision. Their expertise, combined with state-of-the-art equipment, allows the production of custom car parts, auto engines, and various other components faster and with unparalleled accuracy. Customers often highlight the company’s competitive pricing and rapid turnaround times, making Anco Precision a cornerstone in the engine machine shop Florida community.

Diverse Industrial Applications

What sets Anco Precision apart in the bustling engine machine shop Florida arena is its ability to cater to a wide array of sectors, offering tailored solutions to meet specific client requirements. Whether it’s CNC milling, CNC turning, or rapid prototyping, Anco has the capability to serve government agencies, product designers, and educational institutions with equal proficiency.

The company excels in handling complex projects that involve diverse applications, such as medical instruments, aircraft components, and electronic devices. Customers appreciate the unique opportunity to receive instant quotes via Anco’s online machine shop by simply submitting drawing files, a feature that streamlines the project initiation process significantly.

Operating from Monday to Friday, Anco Precision extends its services to a varied clientele, from individual inventors to large-scale businesses. This adaptability underlines their commitment to fulfilling the diverse manufacturing needs across the engine machine shop Florida landscape.

Customer-Centric Approach

At the heart of Anco Precision’s operation is a steadfast dedication to customer satisfaction. Testimonials abound with praise for the company’s attention to detail, exceptional service quality, and a keen focus on meeting deadlines with precision. The machine shop’s reputation for being a reliable partner is further strengthened by its commitment to delivering consistent quality at competitive rates.

This commitment is evident in the seamless communication channels Anco Precision maintains with its clients, fostering relationships built on trust and transparency. Clients seeking engine machine shop Florida services continually find value in the expert guidance and professional advice offered by Anco’s seasoned team.

The ability to cater to both niche and broad-scale manufacturing requirements without compromising on quality is what makes Anco Precision a standout choice. Their dedication to excellence ensures they remain at the forefront of the engine machine shop Florida industry, providing innovative solutions that are as effective as they are efficient.

What are the common misconceptions about precision in CNC machining?

Many individuals believe that CNC machining is purely automated and doesn’t require skilled operators, but this isn’t entirely accurate. While CNC machines are incredibly precise, human expertise is essential in setting up, programming, and maintaining these machines to ensure optimal performance. Experienced machinists like those at Anco Precision bring a wealth of knowledge to the table, fine-tuning each process to achieve the highest quality output. People often overlook the importance of this human element, assuming machines alone handle everything. In reality, it’s the synergy of technology and human skill that defines success in CNC machining. Have you ever considered what aspects of a project require human insight over automation?

How does CNC machining enhance efficiency in the automotive sector?

CNC machining offers remarkable efficiency by drastically reducing the time required for manufacturing complex parts compared to traditional methods. The ability to quickly switch between different product designs and maintain precision ensures that manufacturers like Anco Precision can meet tight deadlines and changing demands without sacrificing quality. For example, imagine needing a custom engine component; CNC technology allows for rapid prototyping and production, getting you back on the road faster. This efficiency supports not only individual projects but also large-scale automotive productions where time is of the essence. What efficiencies do you think could further revolutionize the automotive industry?

Why is customer satisfaction a key focus for automotive machine shops?

Customer satisfaction is crucial because it builds trust and fosters long-term relationships, which are vital for the sustained success of machine shops. At Anco Precision, the emphasis on customer satisfaction translates into personalized service, transparent communication, and a commitment to quality. This ensures that clients receive the value they expect, reinforcing trust and loyalty. An anecdote from our experience involves a client needing an urgent repair for a racing car component. The swift response and precise work we provided ensured their participation in the event, showcasing how our customer-focused approach makes a real difference. How has customer satisfaction played a role in your interactions with service providers?

What are the key benefits of sustainable practices in automotive machining?

Sustainable practices in automotive machining lead to reduced environmental impact and cost savings in the long run. By optimizing material usage and energy consumption without sacrificing quality, companies like Anco Precision contribute to a greener future while maintaining competitive pricing. For instance, using recycling practices and energy-efficient equipment helps lower production costs, benefiting both the environment and the business. These practices align with the growing demand for sustainable solutions in all industries. Considering the global shift towards sustainability, how do you think these practices could transform other sectors?

How do automotive machine shops handle diverse industrial applications?

Automotive machine shops excel in handling diverse applications by leveraging advanced technology and skilled personnel. Anco Precision, for example, utilizes CNC milling, turning, and rapid prototyping to accommodate a variety of industries such as aerospace, medical, and marine, alongside automotive. This adaptability is powered by our expertise in crafting everything from custom car parts to intricate aerospace components. By continuously evolving our methods and technologies, we’re able to cater to unique client needs across different sectors. Have you considered how such versatility could benefit your industry’s manufacturing needs?

What should customers consider when choosing an engine machine shop in Florida?

When selecting an engine machine shop in Florida, customers should evaluate the shop’s experience, range of services, and commitment to precision. Anco Precision stands out with over 40 years of experience and a broad spectrum of services, from CNC machining to screw machining. Checking references and testimonials can also provide insights into a shop’s reliability and quality of service. For instance, our clients continually commend us for our quick delivery times and competitive pricing, underscoring our dedication to excellence. What factors do you value most when selecting a service partner for your projects?

How is the machining industry expected to evolve in the coming years?

The machining industry is set to evolve with advancements in automation, AI integration, and sustainability. Shops like Anco Precision are at the forefront, embracing new technologies that promise greater efficiency and precision. The future will likely see more environmentally friendly processes and smarter machines that require less intervention, leading to faster turnarounds and improved quality. Additionally, the industry’s shift towards more customized solutions will drive innovation in service offerings. In light of these changes, how do you envision the role of traditional skills adapting to new technologies?

Resources

- National Institute of Standards and Technology (NIST) – Official website of NIST, a leading organization in developing and promoting measurement standards.

- Society of Manufacturing Engineers (SME) – SME’s website provides valuable resources and information for professionals in the manufacturing industry.

- American Society of Mechanical Engineers (ASME) – ASME’s website offers insights and standards related to mechanical engineering and related fields.

- National Academies Press – The official site for publications by the National Academies of Sciences, Engineering, and Medicine.