Versatility and Importance of EDM Wire Cutting

Electrically Discharge Machining (EDM) Wire Cutting is an advanced machining process that uses electrical discharges to cut through conductive materials with remarkable precision. Utilized across various industries, this method is particularly effective for complex shapes and fine details that are difficult to achieve with traditional cutting methods. Its ability to maintain tight tolerances makes it invaluable in fields requiring high precision, such as aerospace, automotive, and medical manufacturing.

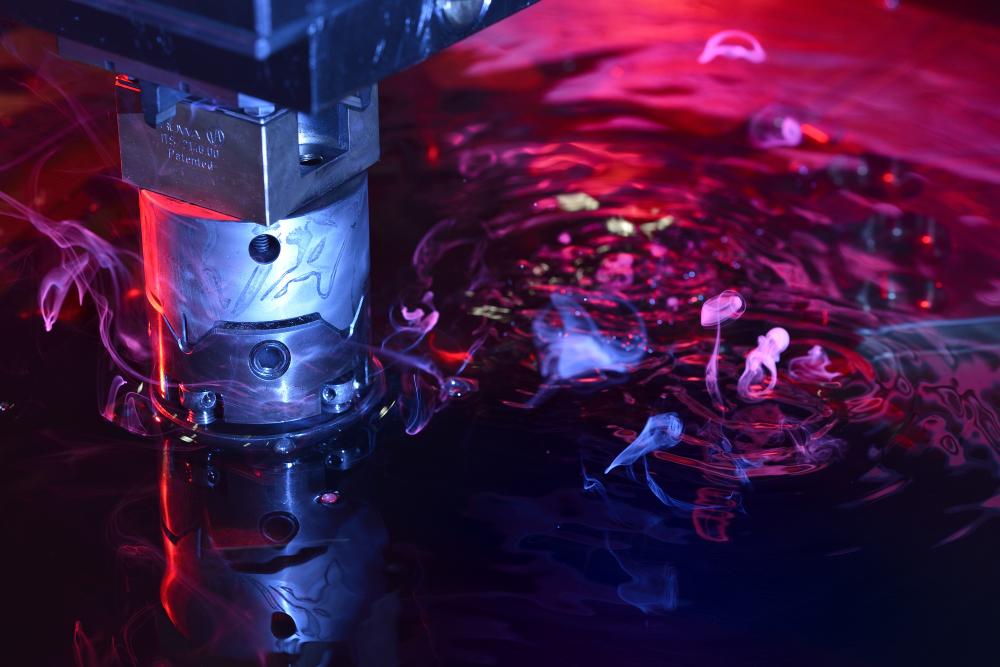

At Anco Precision Inc., the expertise in EDM Wire Cutting is backed by over four decades of experience. The company’s state-of-the-art equipment and highly trained machinists ensure that even the most intricate designs are realized to perfection. The process involves a thin wire, usually made of brass, which acts as an electrode. The wire passes through the workpiece, cutting it while submerged in a dielectric fluid that controls sparking and flushes away debris.

How EDM Wire Cutting Benefits Different Industries

EDM Wire Cutting serves a broad spectrum of industries due to its unparalleled precision. In the aerospace sector, it facilitates the production of components with intricate geometries and high-strength materials, ensuring safe and efficient aircraft operation. For the automotive industry, EDM Wire Cutting allows for the creation of detailed parts required in engine components and intricate gears.

The medical industry also greatly benefits from the accuracy of EDM Wire Cutting. It is essential in manufacturing complex surgical instruments and implants where precision is non-negotiable. Anco Precision Inc.’s use of this technology ensures that each part adheres to strict medical standards, contributing to the safety and efficacy of medical devices.

Anco Precision’s reputation for quality and precision extends to the marine and electronic device sectors, where the ability to produce finely detailed parts is crucial. By employing EDM Wire Cutting, Anco Precision helps clients overcome manufacturing challenges, enabling them to innovate with confidence.

Experiences and Insights from the Shop Floor

In the words of a seasoned machinist at Anco Precision, “EDM Wire Cutting is as much an art as it is a science. Every project teaches us something new, and this continuous learning keeps us ahead in the industry.” This hands-on perspective underscores the skill and dedication required to master the intricacies of EDM Wire Cutting.

Customer testimonials often highlight the transformative role that EDM Wire Cutting plays in their projects. One satisfied client noted, “The precision we achieved with EDM Wire Cutting was beyond our expectations. Anco Precision delivered parts that fit perfectly, which was crucial for our project’s success.” Such feedback is a testament to the process’s reliability and precision.

For those navigating the complexities of manufacturing, the insights and experiences shared by Anco Precision staff provide invaluable knowledge. These stories not only highlight the technical aspects of EDM Wire Cutting but also the commitment to excellence that drives Anco Precision forward, ensuring their status as industry leaders.

Embracing Innovation with EDM Wire Cutting

Anco Precision Inc. continuously embraces innovation by integrating EDM Wire Cutting into its suite of services, reflecting the company’s commitment to meeting diverse client needs. This innovative spirit ensures that Anco Precision can offer solutions that extend beyond conventional boundaries, whether it’s creating complex geometries or achieving the highest precision standards.

The adaptability of EDM Wire Cutting has positioned it as a cornerstone technology at Anco Precision, enabling the company to tackle challenging projects with finesse. The ability to offer rapid prototyping while maintaining exact specifications provides a competitive edge, allowing customers to bring their most ambitious projects to life efficiently and cost-effectively.

Being at the forefront of technology means continuously seeking improvements, and Anco Precision’s openness to exploring new techniques within EDM Wire Cutting exemplifies its growing expertise. The commitment to perfection, supported by cutting-edge technology, underlines why Anco Precision remains a trusted partner for customers across multiple sectors.

EDM Machining: A Deep Dive

Electrical Discharge Machining, known in the industry as EDM Machining, is a sophisticated process that utilizes electrical discharges to shape metal with high precision. At Anco Precision Inc., we’ve seen this technology evolve and have integrated it into our services to address complex machining challenges. This method excels in crafting intricate shapes on electrically conductive materials without the physical contact typical in traditional machining. Our team has found EDM Machining indispensable when producing delicate components for industries such as aerospace and medical, where precision and tolerances are not just desired but essential.

The process works by generating a series of electric sparks between an electrode and the workpiece. This erodes the material, allowing for the creation of detailed and complex shapes. It’s especially beneficial when dealing with hard metals or when the design demands intricate detailing like sharp internal corners or deep cavities. EDM Machining also leaves an impressively smooth surface finish, an aspect our clients in the automotive sector have particularly appreciated.

Applications and Advantages of EDM Machining

At Anco Precision Inc., we utilize EDM Machining for its numerous advantages, which make it a preferred choice in scenarios where conventional machining might fall short. This technique is well-suited for creating complex geometries and operates without exerting mechanical stress on the material, preserving the integrity of delicate parts. We’ve leveraged this in manufacturing sophisticated medical devices and intricate aerospace components.

Some of the standout benefits of EDM Machining include its ability to handle hard materials and produce smooth finishes with minute tolerances, often unattainable through other methods. This precision is particularly valuable in creating burr-free components, which are crucial in crafting implants and other medical instruments. At Anco Precision, our ability to deliver such high-quality outcomes has garnered us praise across different sectors, reinforcing our reputation as a leader in precision machining.

Although it’s an energy-intensive process, the added precision, and finish achieved with EDM Machining can justify the costs, especially when dealing with difficult-to-machine materials. Our clients often find that the benefits outweigh the negatives, particularly when the parts are critical components of larger assemblies where performance and reliability cannot be compromised.

Challenges and Personal Insights

While EDM Machining offers significant benefits, it does come with certain challenges. Energy consumption is a primary concern, especially as industries strive towards sustainability. At Anco Precision, we’ve addressed this by optimizing our processes and exploring alternative energy options to mitigate this impact. The size limitations inherent to EDM machines can also be a hurdle; however, we creatively leverage our CNC capabilities to complement EDM, enabling us to handle a variety of project sizes seamlessly.

Our experienced technicians, trained meticulously to harness the full potential of EDM Machining, navigate these challenges with ease. Their expertise, combined with our investment in cutting-edge technology, ensures that even the most complex projects are executed flawlessly. Anecdotally, a memorable project involved machining a series of micro-holes for a client’s prototype, where traditional methods failed to deliver, but EDM rose to the occasion, affirming its value in precision manufacturing.

These challenges notwithstanding, EDM Machining remains a core part of our service offering at Anco Precision. We continually invest in updating our technology and training our staff to ensure we are at the forefront of machining innovation, ready to tackle even the most demanding projects our clients entrust to us. Our commitment to quality and precision ensures that we consistently meet and exceed industry standards.

Precision EDM Services

The ever-evolving field of Electrical Discharge Machining (EDM) has carved a niche for itself in industries requiring intricate precision and efficient production processes. When searching for ” EDM Services Near Me,” it’s not just about proximity but also the quality and reliability of service providers. As a leader in the machining industry, Anco Precision Inc. embodies these qualities, offering tailored solutions that accommodate the most complex needs. Their family-owned ethos guarantees personalized attention, ensuring each project receives the meticulous care it deserves.

Recognizing the diverse demands of sectors like aerospace, medical, and automotive, Anco Precision leverages state-of-the-art technology to deliver unmatched precision. Their dedicated team of machinists is adept at employing cutting-edge equipment to produce high-quality components, ensuring clients receive the best ” EDM Services Near Me” despite geographical distances.

Diverse Industrial Applications

EDM technology empowers industries by providing solutions that mechanical machining cannot achieve. When exploring options for “EDM Services Near Me,” consider Anco Precision’s comprehensive approach to meeting the diverse needs of modern industries. From aerospace companies requiring precision parts to medical devices demanding intricate detail, their expertise spans numerous sectors.

- Automotive: Precision components and parts customization.

- Medical: Intricate devices and high-precision instruments.

- Aerospace: Complex parts manufacturing for high-performance applications.

- Marine: Durable and accurate components for watercraft.

By offering specialized services like CNC milling, turning, and rapid prototyping, Anco Precision ensures that their clients have a one-stop solution for any machining requirement. This versatility positions them as a go-to provider for any search related to “EDM Services Near Me.”

Commitment to Customer Satisfaction

A reputation for excellence hinges on more than just delivering quality products; it thrives on fostering relationships built on trust and reliability. At Anco Precision, customer satisfaction is not a mere promise but a steadfast commitment. Clients have consistently lauded their quick turnaround times and competitive pricing, making Anco Precision a preferred choice for “EDM Services Near Me.”

Feedback from customers highlights the professionalism and attention to detail that Anco Precision brings to every project. Their ability to provide instant quotes via their online platform further streamlines the client experience, ensuring transparency and efficiency from the outset. By merging technical prowess with customer-centric practices, Anco Precision exemplifies the ideal choice for those seeking reliable “EDM Services Near Me.”

What are common misconceptions about EDM Wire Cutting?

One common misconception about EDM Wire Cutting is that it’s a slow process compared to traditional machining. While it’s true that EDM can take longer for certain cuts, the precision it offers often offsets this time difference. At Anco Precision Inc., we’ve found that the ability to achieve complex shapes and maintain tight tolerances often reduces the need for additional finishing processes, ultimately saving time and expense in the long run. Another myth is that EDM is only suitable for large-scale industrial applications. In reality, its precision makes it equally valuable for custom, small-scale projects, like medical implants or fine electronic components. Are there any specific applications you’re curious about, or perhaps a misconception you’ve encountered?

How does EDM Wire Cutting benefit the medical industry?

EDM Wire Cutting is a game-changer for the medical industry, where precision is paramount. At Anco Precision Inc., we’ve used this technique to create intricate surgical instruments and components for medical devices that demand exact specifications. For example, the creation of stents or microsurgical tools often requires the kind of detail and accuracy that only EDM can provide. The process is particularly advantageous because it works on hard materials like titanium, common in medical applications. This translates to higher-quality, reliable products that ensure patient safety and effective treatments. Does this align with your understanding of medical manufacturing needs?

What challenges does EDM Machining present?

Despite its advantages, EDM Machining does present challenges, primarily related to energy consumption and size limitations. Energy costs can be high, given the process’s reliance on electrical discharges. At Anco Precision, we’ve worked to mitigate this through process optimization and exploring sustainable energy options. The size limitation is another factor; our EDM machines have constraints on the dimensions of workpieces they can handle. By integrating CNC capabilities, we’re able to address varying project sizes and complement the strengths of EDM. Have you encountered specific constraints in your projects when considering EDM Machining?

How can EDM Services “Near Me” benefit local industries?

By seeking out EDM Services “Near Me,” local industries can benefit from quick turnarounds, reduced shipping costs, and the ability to collaborate closely with service providers. At Anco Precision, our location in Deerfield Beach, Florida, allows us to work directly with clients in the region to tailor solutions to their unique needs. Whether it’s for prototyping or production runs, proximity can lead to more efficient communication and customization, benefiting industries like marine, automotive, and aerospace. If you’re considering local EDM services, what specific advantages are most important to you?

What advanced insights can you share about embracing EDM innovations?

Embracing EDM innovations means staying at the cutting edge of technology to tackle increasingly complex manufacturing challenges. At Anco Precision, we’ve integrated EDM Wire Cutting into our suite of services to meet diverse client needs. This includes rapid prototyping and achieving exacting specifications, giving us a competitive edge. The key is not just in having advanced equipment but also in continuously training our machinists to adapt and innovate. This approach allows us to turn our clients’ most ambitious projects into reality. What innovations are you most interested in seeing or currently exploring in your field?

Why is commitment to customer satisfaction crucial in EDM services?

Customer satisfaction in EDM services is crucial because it builds trust and fosters long-term partnerships, which are vital in a field that requires precision and reliability. At Anco Precision, we’ve found that our focus on customer service — from providing instant, detailed quotes to ensuring quick turnaround times — sets us apart. Happy clients are more likely to return and recommend our services, helping to sustain and grow our business. Additionally, addressing any issues promptly and effectively shows clients they can rely on us for all their needs. What aspects of customer service do you find most important when choosing a machining partner?

Resources

- National Institute of Standards and Technology (NIST) – Learn about standards and technology advancements in various industries.

- NASA – Explore cutting-edge research and innovations in aerospace technology.

- Medical News Today – Stay updated on medical advancements and industry news.

- SAE International – Access resources on automotive engineering and industry standards.

- Marine Insight – Discover insights and news related to the marine industry.