Introduction to CNC Manufacturing

At the heart of modern manufacturing is CNC (Computer Numerical Control) technology. This revolutionary method has transformed the way we create everything from simple tools to complex components across various industries. By automating the machining process through computer-programmed sequences, CNC manufacturing shops like ours in Deerfield Beach, FL, can produce parts with unparalleled precision and efficiency.

Our Expertise in CNC Manufacturing

Decades of Precision Machining

With over 40 years of experience in the industry, our family-owned CNC manufacturing shop has honed its skills to provide top-tier services in CNC milling, CNC turning, rapid prototyping, and screw machining. Our commitment to precision and quality has earned us a reputation as a trusted partner in a diverse range of sectors, including the marine, automotive, medical, and aerospace industries.

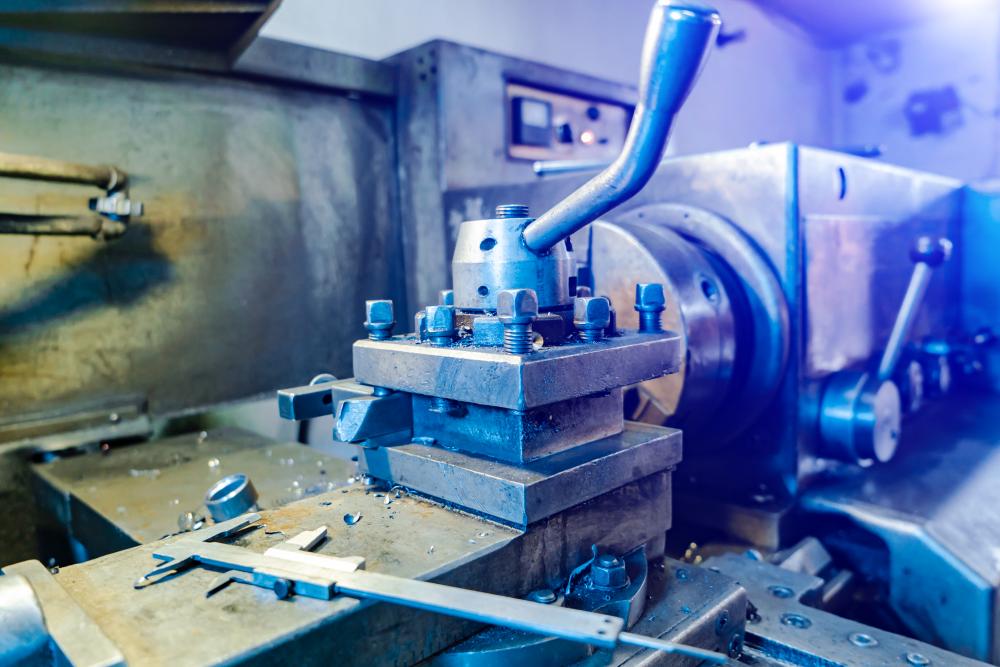

State-of-the-Art Equipment and Skilled Machinists

Our machinists undergo rigorous training to master the latest in CNC technology, ensuring that every project we undertake meets our high standards for precision and excellence. This dedication to quality and detail is what sets us apart and ensures that our customers’ needs are met with precision.

Advantages of Choosing Our CNC Manufacturing Shop

When you partner with us for your CNC machining needs, you’re not just getting a service provider; you’re gaining a partner dedicated to bringing your vision to life with precision and efficiency. Here are just a few reasons why customers choose us:

- Exceptional attention to detail

- Quick deliveries and competitive pricing

- Experienced in handling diverse and complex projects

- Excellent customer service from design to delivery

Industries We Serve

Our experience spans across various fields, making us the go-to CNC manufacturing shop for many industries. From government agencies and large aerospace companies to individual entrepreneurs and small businesses, our capacity to meet a wide range of manufacturing needs is unparalleled.

Custom Manufacturing Capabilities

Every project is unique, and our CNC manufacturing shop is equipped to handle bespoke requirements, whether it’s custom car parts, medical instruments, or aerospace components. Our ability to adapt and innovate ensures that no matter the project, we can deliver with the highest levels of precision and quality.

Getting Started with Our Services

Finding a CNC manufacturing shop that understands your project’s specific needs can be challenging, but we strive to make the process as seamless as possible. Begin by submitting a drawing file through our online platform for an instant quote. This streamlined process helps kickstart your project without delay, ensuring quick turnaround times from design to production.

Why Precision Matters

The Importance of Precision in CNC Manufacturing

Precision in CNC machining is not just about adhering to specifications; it’s about ensuring the longevity, functionality, and reliability of the manufactured components. Our commitment to achieving 100% precision in every project not only meets but exceeds customer expectations, underscoring the quality and dedication we bring to the table.

Case Studies and Success Stories

Our portfolio of successful projects speaks volumes about our capabilities and the trust our clients place in us. From intricate medical devices requiring stringent tolerances to robust components for the automotive industry, our CNC manufacturing shop has consistently delivered products that stand the test of time.

The Future of CNC Manufacturing

As technology evolves, so do the possibilities in CNC manufacturing. Our shop remains at the forefront of innovation, adopting new methodologies and equipment to meet the changing needs of our clients. By staying ahead of industry trends, we ensure that our services not only meet but anticipate the future demands of precision manufacturing.

In conclusion, our CNC manufacturing shop represents the pinnacle of precision machining, offering a comprehensive suite of services tailored to meet the diverse needs of our clients. Our dedication to quality, efficiency, and customer satisfaction has made us a leader in the CNC manufacturing industry. We invite you to experience the difference precision makes by starting your next project with us.

What Makes Precision in CNC Manufacturing So Critical?

Precision in CNC manufacturing isn’t just a buzzword; it’s the heartbeat of all we do at Anco Precision Inc. Imagine a world where the components of the devices you rely on, like your car’s braking system or a medical implant, were made with even the slightest inaccuracy. The results could range from minor inconveniences to critical failures. That’s why we’re committed to achieving 100% precision in every project. Using state-of-the-art equipment and rigorous quality control measures, we ensure that every part meets strict tolerances, guaranteeing its functionality, reliability, and longevity. Think of precision as the unsung hero in the manufacturing process – it might not always be visible, but its absence is definitely felt.

How Do You Choose the Right CNC Manufacturing Shop for Your Project?

Choosing the right CNC manufacturing shop can feel like searching for a needle in a haystack. You’ll want to look for a combination of experience, technology, and customer service. With over 40 years in the industry, our family-owned shop brings a wealth of knowledge to every project. Yet, it’s not just about how long we’ve been around. We continuously invest in the latest CNC technology and training for our machinists, ensuring we’re equipped to meet your project’s unique requirements. But, above all, customer service is key. We treat every project as a partnership, offering personalized service from design to delivery. So, when selecting a CNC shop, consider not just the technical capabilities but also the quality of the partnership they’re offering.

What Are Some Common Misconceptions About CNC Manufacturing?

One common misconception about CNC manufacturing is that it’s only for large-scale industrial applications. However, the truth couldn’t be further from this. At Anco Precision Inc., we cater to a wide range of clients, from individual entrepreneurs to large aerospace companies. Another myth is that custom CNC parts are prohibitively expensive. While price is dependent on the complexity and material of the part, CNC manufacturing can be highly cost-effective, especially for projects that require high precision or involve complex geometries that would be difficult to achieve with manual machining. Lastly, there’s a belief that CNC manufacturing lacks personal touch or customization. In reality, CNC machining offers immense flexibility, allowing for high levels of customization and innovation in projects.

What Does the Future Hold for CNC Manufacturing?

The future of CNC manufacturing is incredibly exciting and is fueled by continuous advancements in technology. At Anco Precision Inc., we are always on the lookout for new ways to push the boundaries of what’s possible in CNC machining. Innovations like 3D printing and AI integration are set to revolutionize the industry by improving precision, reducing waste, and cutting down production times. Additionally, as sustainability becomes more important, we’re exploring ways to make our processes more energy-efficient and to use materials that have a lower environmental impact. The future of CNC manufacturing will be characterized by smarter, faster, and greener production methods, and we’re excited to be at the forefront of this evolution.

What Are the Advantages of CNC Manufacturing Over Traditional Manufacturing Methods?

CNC manufacturing offers numerous advantages over traditional manufacturing methods. The precision and repeatability of CNC machines are unmatched, allowing for complex shapes and high-quality finishes that would be difficult, if not impossible, to achieve manually. Additionally, CNC machines can operate 24/7 with minimal supervision, significantly increasing production efficiency and reducing lead times. Another advantage is the versatility of CNC machines; with the right programming, the same equipment can produce a wide variety of parts, reducing the need for multiple setups and specialized machinery. This agility makes CNC manufacturing ideal for both prototype development and full-scale production, providing a blend of speed, accuracy, and flexibility that traditional methods simply can’t match.

Have you got any questions or thoughts about CNC manufacturing that you’d like to discuss further? Feel free to leave your comments or reach out to us directly. We’re here to help bring your precision machining projects to life.

CNC Manufacturing Resources

- National Institute of Standards and Technology (NIST) – NIST provides valuable resources and guidelines for precision manufacturing and CNC technology.

- Federal Aviation Administration (FAA) – The FAA offers insights into CNC manufacturing regulations and standards in the aerospace industry.

- NASA – NASA’s website includes information on cutting-edge manufacturing technologies used in aerospace applications.

- National Center for Biotechnology Information (NCBI) – NCBI provides resources on CNC manufacturing applications in the medical industry.

- American Society for Engineering Education (ASEE) – ASEE offers educational resources related to CNC technology and precision manufacturing.