Understanding CNC Machining

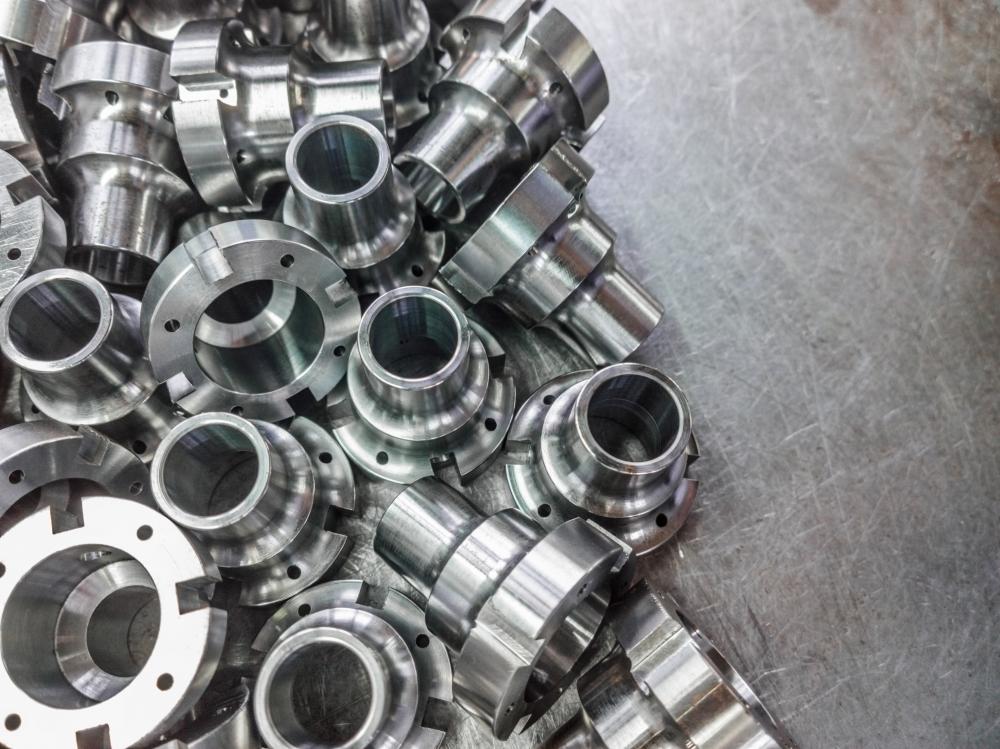

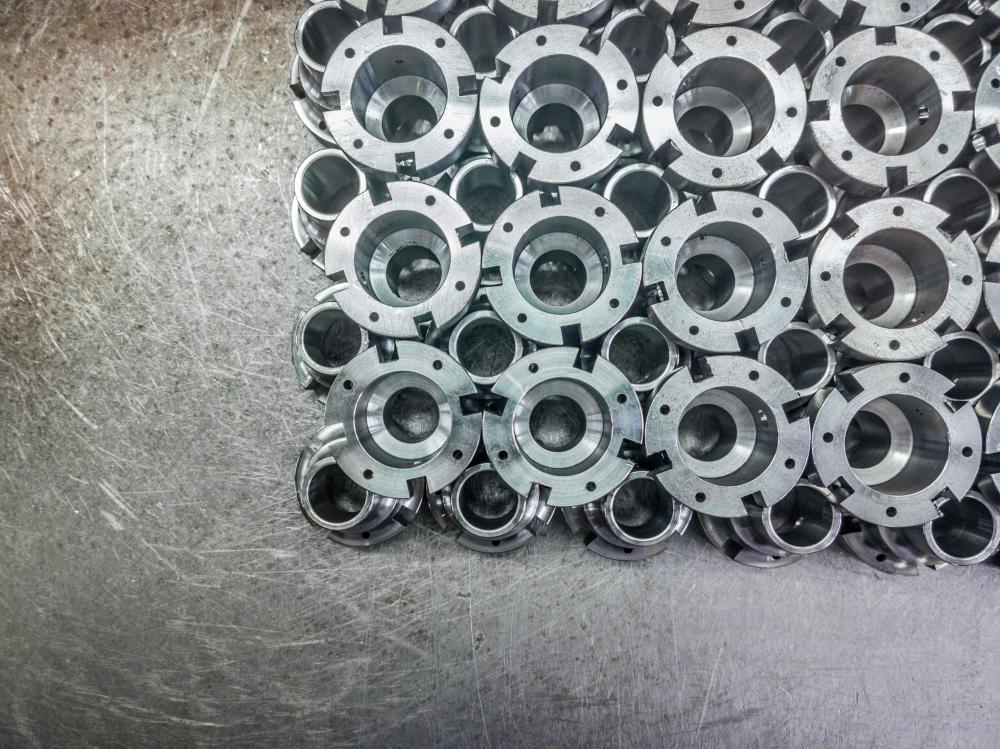

When it comes to precision manufacturing, a CNC machining shop is at the forefront of technology, blending speed and accuracy to produce parts that are integral to a myriad of industries. At the heart of Anco Precision Inc., CNC machining isn’t just about cutting metal; it’s about crafting solutions that bolster innovation across the marine, automotive, medical, and aerospace sectors. Our team, armed with extensive experience and a passion for perfection, takes pride in manufacturing products with 100% precision.

Benefits of CNC Machining

Delving into the world of CNC machining opens up a universe of possibilities. By eliminating manual intervention, CNC machining offers unparalleled accuracy and repeatability. This is especially critical in industries where a micron’s difference can determine the success or failure of a product. Furthermore, the ability to work with a diverse range of materials – from metals to plastics – makes CNC machining a versatile choice for any project.

Why Choose Us?

Choosing Anco Precision Inc. for your CNC machining needs means entrusting your project to a family-owned enterprise that values quality over quantity. Our dedication to delivering exceptional service is reflected in our quick deliveries, competitive pricing, and the glowing testimonials from our diverse clientele. Our machinists undergo rigorous training, ensuring that your projects are in capable hands.

Our Specialties

Specializing in CNC milling, CNC turning, rapid prototyping, and screw machining, we cater to a wide array of manufacturing requirements. Whether it’s creating custom car parts or intricate medical instruments, our expertise is unparalleled. Our state-of-the-art equipment and seasoned professionals make us a leading CNC machining shop, capable of handling projects of any complexity.

Personal Experience

In one memorable project, we were approached by an aerospace company facing a critical deadline for a part essential to their next launch. The complexity of the piece, coupled with the tight timeline, presented a formidable challenge. Leveraging our expertise in rapid prototyping and CNC machining, we not only met the deadline but also exceeded the client’s expectations in terms of precision and quality. This experience epitomizes our commitment to facing challenges head-on and delivering solutions that matter.

Customer Focus

At Anco Precision Inc., we understand that every project is unique. That’s why we offer instant quotes through our online machine shop, simplifying the process of getting your project off the ground. Our team is dedicated to providing personalized service, ensuring that your needs are met with the utmost attention to detail.

We welcome inquiries and quote requests either through our website or by contacting us directly. Our operating hours, Monday to Friday from 8:00 am to 4:30 pm ET, are designed to accommodate our clients’ busy schedules.

Industry Applications

The versatility of CNC machining allows us to serve a broad spectrum of industries. From government agencies to small businesses, and from universities to product designers, our services are sought after for their precision and reliability. The ability to manufacture parts that are integral to products across different sectors underscores the importance of a skilled CNC machining shop.

- Marine

- Automotive

- Medical

- Aerospace

- Consumer Electronics

Choosing the Right CNC Shop

Choosing the right CNC machining shop can make all the difference in your project’s success. Here at Anco Precision Inc., we not only offer the technical expertise and state-of-the-art equipment necessary for high-quality manufacturing but also a partnership that values your project’s success as much as you do. Our team is ready to tackle challenges, exceed expectations, and deliver the precision you need.

Commitment to Quality

Our commitment to quality is not just a motto; it’s the foundation of everything we do. This is demonstrated by our adherence to the highest industry standards, including ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certifications. These certifications are not mere accolades but a testament to our dedication to maintaining the highest levels of quality and precision in each project we undertake.

At Anco Precision Inc., we understand that quality extends beyond the manufacturing process. It encompasses every interaction with our clients, from the initial inquiry to the final delivery of the project. This holistic approach ensures that working with us is not just a transaction, but a collaborative experience that adds value to your projects and drives innovation.

Embrace the Future

As we look to the future, Anco Precision Inc. is poised to continue leading the way in CNC machining services. Our ongoing investment in technology, training, and process improvement positions us to meet the evolving needs of our clients. We invite you to join us on this journey, leveraging the full potential of CNC machining to bring your projects to life.

Visit Anco Precision Inc. at our Deerfield Beach, FL location to learn more about our services and how we can assist with your machining needs. Whether it’s a prototype or a full production run, our team is ready to deliver the precision and quality your projects deserve.

What is CNC Machining?

At Anco Precision Inc., CNC machining is our pride and joy. It’s a process where computers control machine tools to manufacture parts with precision and efficiency. Imagine designing a complex part in a CAD program and then, with the magic of technology, watching as that design becomes a physical part with dimensions accurate to a thousandth of an inch. This isn’t just about cutting metal; it’s about crafting solutions for industries like aerospace, medical, and automotive. CNC machining allows for unparalleled accuracy and repeatability, which is crucial when even a micron’s difference can mean the success or failure of a product.

Why Choose CNC Machining for Your Project?

Choosing CNC machining for your project means opting for a solution that offers versatility, precision, and speed. At Anco Precision Inc., we’ve embraced CNC machining because it eliminates manual errors and ensures products are manufactured with 100% precision. Whether you’re working with metals, plastics, or composites, CNC machining provides the flexibility to bring your diverse project requirements to life. Plus, opting for a family-owned business like ours means you’re choosing a partner dedicated to quality, evidenced by our quick deliveries, competitive pricing, and glowing testimonials.

How Does CNC Machining Contribute to Industry Innovation?

CNC machining is at the heart of innovation across several industries. By allowing for rapid prototyping, businesses can iterate design changes quickly and bring products to market faster than ever before. For example, in a project we did for an aerospace company, we leveraged our rapid prototyping expertise to meet a critical deadline, showcasing how CNC machining not only supports but accelerates the innovation process. This capability ensures that industries ranging from medical to consumer electronics can depend on high-quality, precision parts that meet their evolving needs.

What Makes Anco Precision Stand Out in CNC Machining?

What sets Anco Precision Inc. apart in the realm of CNC machining is our unwavering commitment to quality and our dedication to our clients’ success. Our team of seasoned professionals is equipped with state-of-the-art equipment, allowing us to tackle projects of any complexity. This, combined with our strict adherence to industry standards like ISO 9001:2015 and AS9100D, ensures that each project we undertake meets the highest quality thresholds. Our personalized approach means we closely collaborate with you, offering instant quotes through our online machine shop and ensuring your unique needs are met with precision and care.

How Can CNC Machining Impact the Future of Manufacturing?

The future of manufacturing is bright with CNC machining playing a pivotal role. As we continue to invest in technology, training, and process improvements, Anco Precision Inc. is ready to meet the evolving needs of our clients. CNC machining’s ability to produce complex parts with high precision and speed means that industries can innovate faster, creating products that meet the changing demands of the market. By embracing these advancements, we are not just participating in the future of manufacturing; we are actively shaping it, one precision part at a time.

What Are the Challenges in CNC Machining and How Does Anco Precision Address Them?

One of the challenges in CNC machining is maintaining precision in complex parts or when working with difficult materials. At Anco Precision Inc., we tackle these challenges head-on with our extensive experience and state-of-the-art equipment. Our machinists undergo rigorous training, ensuring they’re equipped to handle any project complexity. Additionally, staying up to date with the latest technology and machining techniques allows us to efficiently work with a wide range of materials, ensuring that even the most challenging projects are completed with the highest quality.

Have more questions or a project in mind? Feel free to reach out or leave your comments and questions below. We’re excited to bring your projects to life with the precision and quality you deserve.

Resources

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory federal agency that promotes innovation and industrial competitiveness by advancing measurement science, standards, and technology.

- International Organization for Standardization (ISO) – ISO is an independent, non-governmental international organization that develops and publishes international standards to ensure quality, safety, and efficiency of products, services, and systems.

- AS9100 Store – The AS9100 Store provides resources and information on the AS9100 standard, which defines quality management system requirements for the aerospace industry.

- IATF Global Oversight – IATF Global Oversight oversees the IATF 16949 standard, which specifies the quality management system requirements for organizations in the automotive industry.

- ISO 13485 – ISO 13485 is an international standard that specifies requirements for a quality management system in the medical devices industry.