The Unique Process of Wire Edm Services

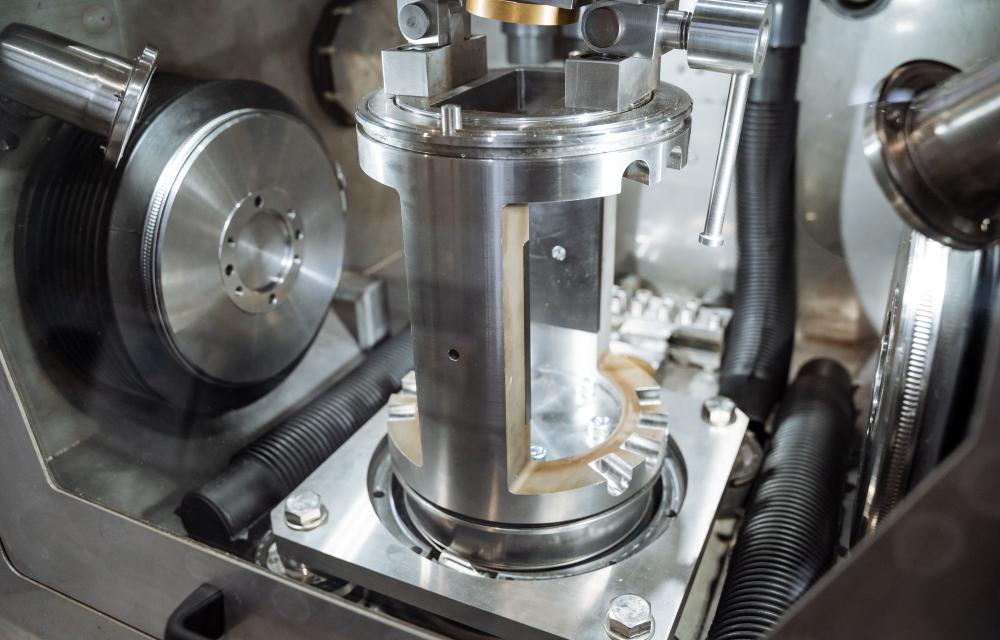

Wire Edm Services offer a distinct method of cutting and shaping metals through a process called Electrical Discharge Machining (EDM). This technology diverges from traditional cutting techniques by using a thin, electrically charged wire to erode metal along a programmed path. This approach results in precise, contact-free cuts, making it particularly suitable for intricate geometries and materials that are sensitive to mechanical stress.

With over 40 years of experience, Anco Precision Inc., a family-owned CNC machine shop located in Deerfield Beach, FL, has mastered this technique, offering unparalleled precision for various industries such as marine, automotive, medical, and aerospace. The precision achieved by wire EDM is indispensable for producing components like medical instruments, aerospace parts, and even custom car components.

Benefits and Precision of Wire Edm Services

One of the primary advantages of Wire Edm Services is the ability to cut hard or exotic alloys without inducing physical stress or deformation. Materials like titanium, hardened steels, and carbides pose challenges for conventional machining methods but are handled efficiently by wire EDM. Anco Precision Inc. utilizes state-of-the-art equipment to ensure that their Wire Edm Services meet the most rigorous industry standards, delivering high-quality results at competitive prices.

Moreover, the accuracy and finishing quality of wire EDM are unmatched, making it the preferred choice for projects that require tight tolerances and superior surface finishes. This precision is achieved through the generation of controlled electrical discharges, which precisely remove material without causing burrs or requiring secondary finishing.

Clients who have collaborated with Anco Precision frequently commend the company’s commitment to detail and prompt delivery of parts. This dedication to excellence is a testament to the specialized training undergone by their machinists and their investment in cutting-edge technology.

Applications and Use Cases for Wire Edm Services

Wire Edm Services find versatile applications across a multitude of industries, catering to diverse needs from prototype creation to mass production. In the medical field, wire EDM is invaluable for crafting components that demand biocompatibility and precision, such as surgical tools and implants.

In the aerospace sector, where precision and reliability are paramount, Wire Edm Services are used for manufacturing turbine components and other mission-critical parts. Anco Precision Inc.’s expertise in this area ensures that aerospace manufacturers receive parts that adhere to the highest standards of safety and performance.

The automotive industry also benefits from wire EDM, utilizing it for creating intricate powertrain components and custom vehicle parts. The ability to handle complex designs and tight tolerances makes wire EDM an essential tool for automotive prototyping and production.

Expert Perspectives and Industry Insights on Wire Edm Services

The team at Anco Precision Inc. shares valuable insights into the world of Wire Edm Services, emphasizing the importance of precision and attention to detail in every project. One experienced machinist explains how the exacting nature of wire EDM allows for the creation of complex patterns that were once deemed impossible.

Anco Precision also highlights the role of continuous innovation in their operations, showcasing how their adoption of advanced technologies enhances customer satisfaction. Real-world stories from satisfied clients illustrate how precise and timely delivery of parts has helped streamline their production processes, allowing for the creation of high-quality products at reduced costs.

Overall, the commitment of Anco Precision Inc. to excellence in Wire Edm Services is evident in their ability to meet the diverse needs of their clients, providing solutions tailored to specific project requirements. Their long-standing reputation as a leader in CNC machining underlines their dedication to pushing the boundaries of what is achievable through wire EDM technology.

The Intricacies of Wire EDM

In the world of modern machining, Wire EDM, or Electrical Discharge Machining, stands as a pivotal technology, especially in precision-driven industries. Anco Precision Inc., a family-owned CNC machine shop in Deerfield Beach, FL, uses Wire EDM to enhance its precision machining capabilities. This non-traditional machining process uses a thin wire to cut intricate shapes from conductive materials, providing unparalleled accuracy and intricate detailing.

Wire EDM is especially valuable in industries where micro-precision is crucial, such as aerospace and medical device manufacturing. It allows for the creation of complex geometries that would be challenging to achieve with conventional machining techniques. Despite its intricate nature, the Wire EDM process remains efficient, reducing the need for complex tooling and significantly cutting production times.

How Wire EDM Improves Manufacturing

Unmatched Precision

One of the key advantages of Wire EDM is its unrivaled precision. Anco Precision specializes in delivering machining solutions with tight tolerances, a demand that Wire EDM fulfills effortlessly. The technology facilitates the creation of parts with complex shapes and fine details, essential in industries like electronics and automotive. This precision is achieved without applying any mechanical force, which can distort delicate components.

Versatility in Materials

Wire EDM’s versatility with materials is another significant benefit. It’s capable of cutting through various conductive materials, including hard metals like titanium and hardened tool steel. This versatility enables Anco Precision to serve a broad array of sectors, from the production of custom car parts to the crafting of intricate aerospace components. The absence of physical cutting forces makes Wire EDM suitable for delicate materials that may otherwise be prone to damage.

Personal Insights on Wire EDM

From a machinist’s perspective, working with Wire EDM is both an art and a science. The process requires not just technical proficiency but also creativity in solving unique machining challenges. At Anco Precision, machinists leverage their extensive training and experience to maximize the potential of Wire EDM. Their commitment to innovation and excellence ensures that each project, whether it’s an auto engine component or a medical device, is crafted to perfection.

A machinist at Anco once shared his experience about crafting a complex component for an aerospace client. Using Wire EDM, he was able to achieve precision cuts that traditional methods couldn’t offer, underscoring the process’s critical role in advancing aerospace technology. Such anecdotes highlight how Wire EDM not only meets but often exceeds the high standards of quality and innovation demanded in today’s engineering landscapes.

Wire EDM is more than a machining process; it’s a gateway to innovation. For companies like Anco Precision, it opens up new possibilities for creating intricate designs with unmatched accuracy. As industries continue to evolve, embracing advanced technologies like Wire EDM will remain key to maintaining a competitive edge.

What makes the process of Wire EDM unique compared to traditional machining techniques?

Wire EDM, or Electrical Discharge Machining, stands apart from traditional machining methods by using a thin, electrically charged wire to cut through metal. Unlike conventional methods that often apply physical stress or heat, Wire EDM provides a contact-free approach, allowing for highly precise cuts. This process is especially beneficial when working with intricate geometries or materials sensitive to mechanical stress, like titanium or hardened steels. At Anco Precision Inc., we’ve seen firsthand how this method revolutionizes the way we handle complex projects, pushing boundaries further than ever before. Just imagine creating aerospace components with minimal metal wastage and unparalleled accuracy! The non-contact nature ensures no deformation, making it a preferred choice for industries demanding precision and reliability.

Can you explain the main benefits of using Wire EDM over other machining processes?

There are several key advantages to using Wire EDM, particularly its ability to handle hard and exotic alloys without causing physical stress or deformation. For example, materials such as advanced composites used in medical or aerospace applications can be tricky for conventional machining but are handled efficiently with Wire EDM. At Anco Precision Inc., we pride ourselves on delivering products that require tight tolerances and superior surface finishes. Moreover, the elimination of burrs and the need for secondary finishing helps streamline production and reduce costs. Our clients often compliment our ability to meet their stringent requirements with precision and within tight timelines, a testament to our investment in cutting-edge technology and training.

In what industries do Wire EDM services find the most applications?

Wire EDM offers immense versatility and finds applications across multiple industries, notably in sectors where precision is paramount. Whether it’s crafting biocompatible surgical tools or manufacturing turbine components for aerospace, wire EDM proves its mettle time and again. At Anco Precision Inc., we’ve had the privilege of working on projects from diverse fields, including automotive powertrain components and custom parts for high-performance vehicles. Our capacity to work with intricate designs and maintain tight tolerances makes wire EDM invaluable, especially for prototyping and mass production. Picture creating a unique car part that fits perfectly every time–wire EDM makes this possible without the guesswork often involved with other methods.

How do innovations in Wire EDM technology contribute to manufacturing advancements?

Innovation in Wire EDM technology has played a pivotal role in advancing manufacturing processes. At Anco Precision Inc., we continuously explore new technologies to enhance our capabilities, whether through adopting advanced machinery or refining our techniques. Innovations have enabled us to offer improved precision and faster turnaround times, critical factors in meeting client expectations. For instance, our enhanced capabilities have helped aerospace clients streamline their production, achieving higher safety and performance standards. These advancements also reduce tooling costs and simplify the production of complex geometries, which was previously unimaginable. As we embrace these technologies, we invite you to consider how your manufacturing processes could benefit from such cutting-edge innovations.

What are some common misconceptions about Wire EDM, and how do you address them?

One common misconception is that Wire EDM is only suitable for large-scale industrial applications; however, it’s incredibly versatile and can be used for small-scale projects or prototyping as well. At Anco Precision Inc., we’ve worked on everything from medical device components to custom automotive parts, demonstrating the broad applicability of this technology. Another misconception is that Wire EDM is slow and costly. While the initial setup might be more involved, the precision and reduced need for secondary operations often make it more cost-effective in the long run. We’re always happy to discuss these aspects with our clients to emphasize how Wire EDM can be tailored to match specific needs and dispel any myths surrounding its usage.

Resources

- National Institute of Standards and Technology (NIST) – The NIST website provides valuable information on standards, measurements, and technology to support innovation and industrial competitiveness.

- American Society of Mechanical Engineers (ASME) – ASME offers resources and expertise in the field of mechanical engineering, providing a platform for collaboration and knowledge sharing.

- NASA – NASA’s website offers insights into aerospace technology and innovations, showcasing the latest advancements in the field.

- American National Standards Institute (ANSI) – ANSI is a leading authority in setting industry standards, promoting innovation, and enhancing global competitiveness.

- MachiningCloud – MachiningCloud provides a platform for accessing cutting tool data, simplifying the tool selection process for precision machining projects.