Exploring the Essentials of CNC Turning Services

At Anco Precision Inc., CNC Turning Services are an integral part of our commitment to delivering precision and quality. CNC turning utilizes computer-controlled lathes to shape materials into precise cylindrical parts. This process is particularly valuable in industries like aerospace and automotive, where precision is paramount. CNC Turning Services ensure that each component meets exact specifications, reducing human error and enhancing accuracy.

Our seasoned machinists at Anco Precision are trained extensively to handle a variety of materials, from metals like aluminum and titanium to durable plastics. This versatility allows us to cater to a broad range of industries, providing custom solutions for unique manufacturing needs. By mastering CNC Turning Services, our team effectively contributes to advancements in fields ranging from medical to maritime.

Industries and Insights into CNC Turning Services

The versatility of CNC Turning Services proves indispensable across diverse sectors. In the automotive industry, for instance, precise parts such as engine components and transmission shafts benefit from this meticulous process. Anco Precision’s reputation for quick turnaround and consistent quality has made us a preferred partner for automotive manufacturers seeking reliability in their supply chain.

Meanwhile, in the aerospace sector, CNC Turning Services are critical in crafting components that must withstand extreme conditions and adhere to strict safety standards. Our experience at Anco Precision ensures that we deliver components that exceed expectations in both accuracy and durability, contributing to safer and more efficient air travel.

Personal anecdotes from our team highlight the nuances of working with different materials and the challenges of maintaining precision under tight deadlines. Whether it’s a complex project for a defense contractor or a small batch of prototypes for a startup, our experience equips us to handle it all with the highest level of expertise.

Precision and Process in CNC Turning Services

CNC Turning Services at Anco Precision Inc. are underpinned by a rigorous process that emphasizes precision every step of the way. From initial CAD designs to the final machining process, every detail is scrutinized to ensure top-notch results. Our state-of-the-art equipment allows us to achieve exceptional tolerances, vital for industries where even the smallest discrepancies can impact performance.

My colleagues and I often discuss the fascinating interplay between technology and craftsmanship in CNC Turning Services. While machines handle the bulk of precision work, the human touch in understanding material behaviors and making on-the-fly adjustments remains irreplaceable. This blend of automation with artisanal skill sets Anco Precision apart in the machining world.

Beyond machining, the process includes secondary finishing options to enhance the surface quality and functional properties of turned parts. Whether it’s anodizing for corrosion resistance or polishing for enhanced aesthetic appeal, our finishing services complement the inherent precision of CNC Turning Services.

Selecting a CNC Turning Services Provider

When selecting a provider for CNC Turning Services, the decision should factor in expertise, technology, and customer service. At Anco Precision, we pride ourselves on our long-standing reputation for delivering excellence in all these areas. Our clients have consistently praised our attention to detail and dedication to meeting tight deadlines without compromising quality.

One often-overlooked aspect is the provider’s capability to innovate and offer solutions for complex challenges. At Anco Precision, we routinely push the boundaries of conventional manufacturing approaches, developing new methods to optimize the efficiency and precision of CNC Turning Services. This innovation is crucial for clients who require not just a part, but a partner in developing groundbreaking products.

Lastly, understanding the provider’s engagement process, from quoting to delivery, can give insight into their operational efficiency and reliability. Anco Precision leverages an efficient quoting system that provides instant quotes, allowing clients to kickstart projects without delay. This streamlined approach reflects our overall commitment to customer satisfaction and excellence in CNC Turning Services.

CNC Turning: In-Depth Exploration

What Is CNC Turning?

CNC Turning is a fascinating and intricate machining process that revolves around transforming raw materials into precision components. By rotating the workpiece rather than the cutting tool, CNC Turning essentially chisels away the material with a stationary tool to achieve the desired shape. At Anco Precision Inc., where I’ve had the pleasure of working, this process is an art form mastered through decades of experience. We pride ourselves on crafting components that are not only precise but also reliable across various industries.

What sets CNC Turning apart is its versatility in creating complex shapes. Whether it’s crafting components for aerospace designs or producing specialized medical instruments, CNC Turning is the go-to technique for fine details and precision. The ability to combine different operations like drilling and threading within the same setup is a game changer in efficiency and quality.

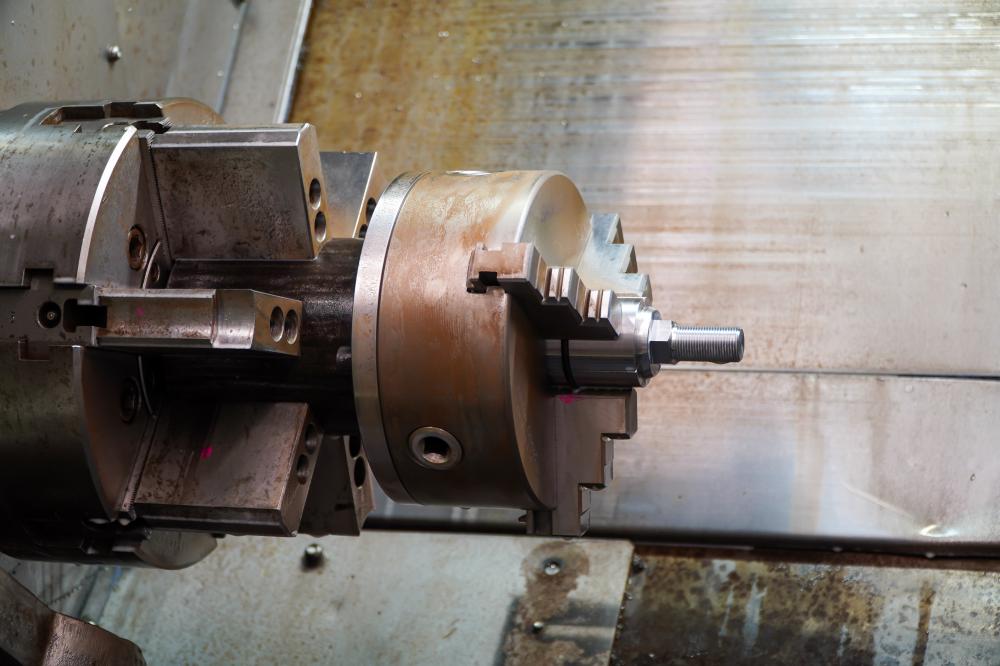

The Machinery Behind CNC Turning

The magic begins with the CNC lathe or turning center, a powerhouse of modern engineering. These machines are equipped with multiple turrets and spindles, allowing them to perform various operations simultaneously. At Anco Precision, our cutting-edge equipment ensures that we can push the boundaries of what’s possible, delivering impeccable components with unparalleled precision.

Our machinists are the unsung heroes who breathe life into these machines. Their expertise transforms raw stock into intricate designs. The training and precision at our shop ensure every cut, every groove, and every thread is executed flawlessly. It’s this commitment to quality that keeps our clients coming back for more.

Heat management is another crucial aspect of CNC Turning. Temperature control is vital to maintain tool durability and workpiece integrity. Advanced cooling systems and quality materials ensure that even under intense conditions, the machine maintains optimal performance.

Versatility, Precision, and Safety in CNC Turning

Precision as a Cornerstone

At the core of CNC Turning is precision, which is not merely a goal but a standard upheld at Anco Precision. This technology allows for extremely tight tolerances, making it indispensable in industries where precision is paramount. From marine to automotive applications, the consistency achieved through CNC Turning ensures parts fit perfectly and function reliably.

Versatility of Applications

One of the remarkable attributes of CNC Turning is its flexibility across materials and applications. Whether dealing with metals, plastics, or composites, CNC Turning processes can be tailored to the specific requirements of the material. This adaptability is a cornerstone at our shop, enabling us to meet diverse needs from prototyping to full-scale production.

Moreover, the ability to integrate milling and drilling operations within CNC Turning centers provides unparalleled versatility. This integration reduces setup times, streamlines production, and enhances the complexity of parts that can be produced without needing additional operations.

Prioritizing Safety

Safety is inherently woven into every aspect of CNC Turning. The process encloses the machining area, minimizing risk to operators and keeping potential hazards at bay. At Anco Precision, we’ve cultivated a culture where safety practices are second nature, and our machinery reflects this commitment to protecting our team.

- Operators are trained to address machine errors swiftly and safely.

- Routine maintenance is conducted to ensure all safety mechanisms function correctly.

- Workspaces are organized to prevent accidents and ensure a safe working environment.

It’s this unwavering focus on safety that allows us to maintain productivity without compromising on quality or the well-being of our staff.

Unique Insights into CNC Turning

Anecdotal Insights

I remember when we worked on a project for a small aerospace company needing customized components on a tight schedule. The agility of our CNC Turning capabilities allowed us to deliver high-precision parts quickly, earning us not just satisfied customers, but partners. This project exemplified how our expertise can turn the impossible into achievable feats.

There’s an undeniable artistry in watching a raw piece of metal evolve into a polished component. Every step is meticulously planned, every cut carefully calibrated. It’s a dance between precision and innovation, one that we at Anco Precision are proud to perform daily.

Innovative Approaches

Innovation is at the heart of CNC Turning. Embracing new materials, exploring novel tool designs, and continuously enhancing our methodologies are integral to keeping ahead in the industry. At Anco Precision, we explore cutting-edge software enhancements and collaborate with researchers to push the limits of what CNC Turning can accomplish.

This spirit of innovation is reflected in our commitment to continuous improvement. By leveraging the latest technologies, we not only meet but exceed industry standards, providing solutions that are both forward-thinking and practical.

Precision in CNC Turning Florida

Having worked closely with Anco Precision Inc., a family-owned CNC machine shop located in Deerfield Beach, Florida, I can attest to the unparalleled attention to detail that the company brings to every project. With over 40 years of expertise, Anco’s commitment to delivering 100% precision ensures that every piece is crafted to exact customer specifications. This attention to detail is not merely about adhering to measurements but about understanding the unique requirements of each client and delivering products that consistently exceed expectations.

In the realm of CNC Turning Florida, the services offered by Anco Precision stand out because of the team’s dedication to continuous improvement through regular training and investment in modern technology. Whether it’s crafting custom car parts or components for aerospace applications, the team’s use of state-of-the-art equipment guarantees high precision and exceptional quality. The machinists at Anco are not just operators but craftsmen, melding technology with creativity to transform complex designs into high-functioning parts.

Diverse Industrial Applications

Anco Precision Inc. serves a wide variety of industries, making it a key player in CNC Turning Florida. Their facility is equipped to handle projects ranging from automotive to aerospace, demonstrating a versatility that is rare in the industry. The ability to pivot between such varied production needs is supported by the comprehensive training of Anco’s staff and their deep understanding of each industry’s unique requirements. For many clients, Anco’s capacity to deliver rapid prototyping as well as full-scale production runs is a game-changer, enabling them to bring products to market in a more efficient manner.

Beyond just the technical capabilities, what I find truly remarkable is the personalized service each client receives. From government agencies to solo inventors, Anco adapts its services to meet very specific project needs. This customer-centric approach ensures not only satisfaction but also lasting partnerships, as evidenced by the glowing testimonials from diverse sectors including medical and marine. Clients repeatedly praise Anco’s quick turnaround times and competitive pricing, elements that are crucial in today’s fast-paced manufacturing environment.

Streamlined Client Communication

A critical component of Anco Precision’s success in CNC Turning Florida is their streamlined communication with clients. The company offers an innovative approach to project kickoffs–clients can simply submit their designs online and receive instant quotes. This immediacy in initiating projects doesn’t just save time; it empowers clients to move forward with confidence, knowing exactly what to expect in terms of cost and timeframes. This level of transparency builds trust and fosters stronger client relationships.

Anco Precision goes beyond just making parts; they are partners in problem-solving, often collaborating with clients to refine designs for manufacturability and cost-efficiency. This collaborative spirit, coupled with a robust online presence, ensures that Anco remains accessible and responsive, making them a preferred choice for CNC Turning Florida. Their commitment to customer satisfaction is evident not just in their finished products but in the seamless experience they create for each client.

Operating from Monday to Friday and welcoming inquiries throughout the workweek, Anco’s team is always ready to engage with both current and potential clients. This open-door policy promotes a sense of community and partnership that is essential in maintaining long-term business relationships. Whether you’re in need of complex aerospace components or bespoke automotive parts, Anco Precision Inc. stands ready to deliver with precision, reliability, and outstanding service.

What makes CNC Turning an essential process for precision manufacturing?

CNC Turning is crucial in precision manufacturing because it transforms raw materials into highly accurate cylindrical components. This process is indispensable for industries like aerospace and automotive, where even slight deviations can lead to significant performance issues. The computer-controlled nature of CNC Turning minimizes human error, ensuring each part meets exact specifications. At Anco Precision, we’ve seen first-hand how this technology allows us to deliver components with exceptional tolerances, often outperforming manual techniques. For instance, when producing engine components, CNC Turning’s precision ensures that each part fits seamlessly, reducing wear and tear over time. Are there any specific components or industries you’re curious about in terms of CNC Turning applications?

How does Anco Precision Inc. ensure safety while maintaining high precision in CNC Turning operations?

Safety and precision go hand in hand at Anco Precision. We’ve integrated numerous safety protocols into our CNC Turning operations to protect both our team and our clients’ projects. Our machinery encloses the machining area, drastically minimizing operator risk. For example, during a high-stakes aerospace project, our enclosed setups allowed us to perform intricate tasks without compromising safety. Additionally, our machinists receive extensive training to swiftly address potential errors, ensuring uninterrupted precision. Regular maintenance checks keep our equipment in top condition, allowing us to maintain the highest safety standards without sacrificing the quality of our outputs. What specific safety measures do you consider most important in manufacturing processes?

Why is versatility a key advantage of CNC Turning, and how does Anco Precision adapt this to various materials?

The versatility of CNC Turning is truly one of its standout advantages, as it adeptly handles a wide array of materials–from metals like aluminum and titanium to robust plastics. This adaptability allows us to cater to the unique demands of different industries, from crafting light yet durable aerospace parts to creating intricate medical instruments. At Anco Precision, our machinists’ expertise is key to optimizing the process for each material type. For instance, we adjust parameters like cutting speed and tool choice based on the material’s properties, ensuring efficient and precise results. This level of customization is a game-changer, especially when dealing with novel material challenges. Have you encountered specific materials that present unique challenges or opportunities in your field?

How does Anco Precision ensure efficient communication with clients throughout the CNC Turning process?

Efficient communication is the backbone of our operations at Anco Precision. We leverage a streamlined approach that begins with our online quote system, offering instant feedback once designs are submitted. This immediacy builds confidence and clarity from the project’s outset. For example, during a time-sensitive project for a medical client, the ability to receive instant quotes allowed us to start production swiftly, meeting tight deadlines without compromising quality. Furthermore, we maintain open lines of communication throughout the process, engaging clients in collaborative problem-solving to refine designs and enhance manufacturability. Our commitment to transparency not only fosters trust but transforms our clients into partners. How do you prefer to communicate with your manufacturing partners to ensure smooth project execution?

What unique insights can Anco Precision offer about CNC Turning in Florida specifically?

Operating in Florida provides us at Anco Precision with unique insights into the regional demands and opportunities of CNC Turning. Florida’s diverse industrial landscape means we work with a wide array of sectors, from aerospace companies to marine manufacturers. The state’s proximity to key shipping routes also offers logistical advantages, enabling us to deliver parts quickly and efficiently to both domestic and international clients. Our 40 years of experience in this region have allowed us to develop a keen understanding of local market needs and preferences, ensuring we remain a preferred partner for entities seeking reliability and excellence in CNC Turning. Whether you’re interested in regional manufacturing trends or specific industry applications, feel free to reach out for a deeper conversation about CNC Turning’s impact in Florida.

Resources

- National Institute of Standards and Technology (NIST) – Official website of NIST providing standards, measurements, and technology information.

- NASA – Homepage of the National Aeronautics and Space Administration, offering insights into aerospace technology and exploration.

- Columbia University – School of Engineering – Access to academic resources and research in engineering disciplines.

- Automotive Fleet – Resource for automotive industry updates and insights into fleet management.

- Federal Aviation Administration (FAA) – Official site of the FAA providing information on aviation safety and regulations.