Mastering CNC Turning Florida

At Anco Precision Inc., CNC Turning Florida is more than just a service–it’s an art form perfected over decades. In Deerfield Beach, our family-owned shop has been crafting precision machined components for more than 40 years, earning a trusted reputation across diverse industries. Our expertise extends to marine, automotive, medical, and aerospace sectors, where precision cannot be compromised. Having worked with a myriad of materials and designs, we know that each project presents its own challenges, but our commitment to customer satisfaction remains unwavering. Clients often commend our team’s ability to adapt and innovate, ensuring their visions come to life with exacting accuracy.

What sets our CNC Turning Florida services apart is the human touch behind our machines. Every technician at Anco Precision undergoes extensive training, allowing them to operate the latest machinery with ease. We balance precision and creativity, translating complex technical drawings into tangible components that meet rigorous industry standards. Our customers appreciate knowing their projects are handled by experienced hands who understand the intricacies of each sector we serve. This personalized approach not only guarantees exceptional results but also fosters lasting partnerships.

The Anatomy of Precision in CNC Turning

State-of-the-Art Equipment

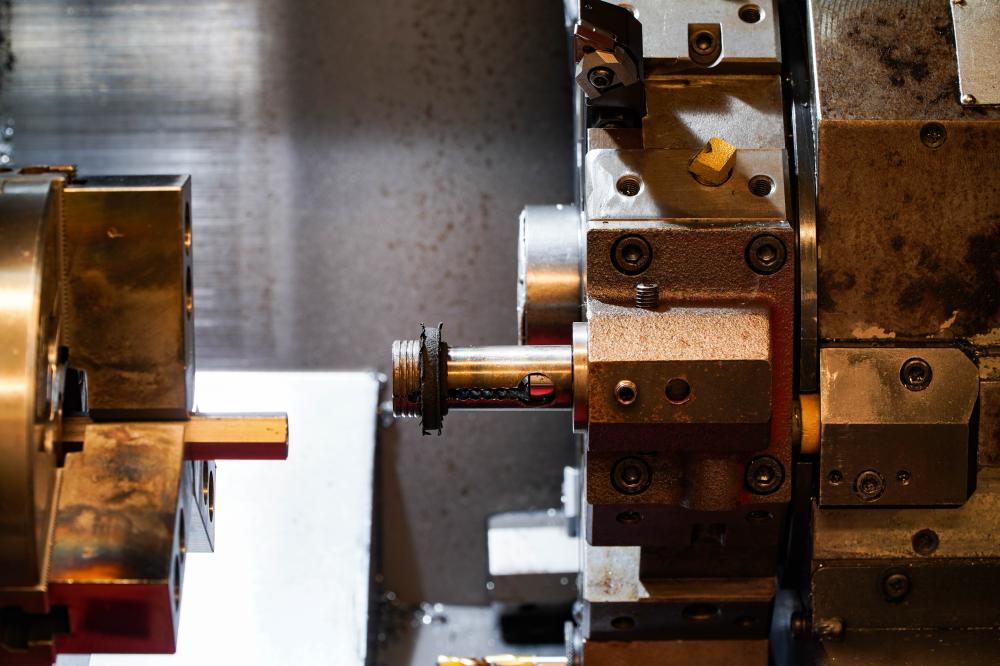

The heart of CNC Turning Florida at Anco Precision lies in our state-of-the-art equipment. Our machinery is designed to handle intricate geometries and perform rapid prototyping with remarkable precision. Imagine crafting custom car parts or intricate medical instruments that must adhere to unforgiving tolerances. Our advanced CNC turning machines are configured to meet these challenges head-on, ensuring each part adheres to stringent specifications.

Our machine shop is equipped with the latest technology, enabling us to maintain the highest standards of precision and efficiency. By leveraging cutting-edge tools, we can deliver high-quality products with quick turnaround times, an aspect highly appreciated by our clientele. Whether you require bulk orders or single prototypes, our equipment ensures consistent quality, time after time.

Commitment to Quality

At Anco Precision, quality is not just a standard–it’s a promise. Our machinists are dedicated to continuous improvement, always seeking new ways to enhance our CNC Turning Florida offerings. This commitment involves regular training sessions to keep abreast of emerging technologies and techniques. It is this dedication to staying ahead of the curve that enables us to deliver unparalleled precision, even as industry demands evolve.

Tailored CNC Solutions in Florida

Every client and project is unique, demanding solutions that are equally distinct. For those seeking CNC Turning Florida services, Anco Precision offers an array of options to suit diverse manufacturing needs. From crafting components for NASA telescopes to producing critical medical devices, our range of services is as varied as our clientele. Our experienced machinists bring creative problem-solving to the fore, ensuring every project is executed flawlessly.

Working with Anco Precision means gaining access to tailor-made solutions crafted specifically for your requirements. Our ability to customize processes allows us to accommodate special requests and integrate specific features seamlessly into the design. This flexibility is a testament to our adaptability and resourcefulness, qualities that have become hallmarks of our reputation.

One of the key advantages of choosing Anco Precision for CNC Turning Florida is our personalized service, which extends from the initial consultation through to the final product. Our online tool enables clients to receive instant quotes, simplifying project initiation. By offering direct communication channels, we ensure that every customer feels valued and informed throughout the creation process, making each collaboration a partnership based on trust and transparency.

Precision Partnerships: Our Impact Across Industries

Our expertise in CNC Turning Florida has ripple effects beyond our workshop doors and into the industries we serve. For example, aerospace companies depend on our precision to ensure safety and performance in aircraft parts. Likewise, medical device manufacturers trust us to produce components that are both reliable and life-enhancing. Our work in the automotive and marine sectors similarly demonstrates how precision machining can lead to significant improvements in product performance and longevity.

It’s not just large industries that benefit from our expertise. Inventors, product designers, and educational institutions also find our CNC turning services indispensable. Whether it’s developing new prototypes or refining existing designs, our clients know they can rely on our knowledge and craftsmanship to bring their creations to life. This diversity in our client base is a testament to the versatility and reliability of Anco Precision’s services in CNC Turning Florida.

Our family-owned business is built on strong values: integrity, trust, and excellence. As we continue to expand our capabilities and reach, our goal remains to provide unparalleled precision and service in every project we undertake, regardless of scale. This commitment has cemented Anco Precision as a leader in the CNC machining industry, a reputation we proudly uphold with every part we produce.

CNC Turning Explained

CNC Turning, a pivotal process in the realm of precision machining, revolves around the art of crafting cylindrical parts with meticulous accuracy. At Anco Precision Inc., located in Deerfield Beach, FL, our seasoned team exemplifies proficiency in this craft. CNC Turning involves rotating a workpiece while a cutting tool remains stationary, delicately sculpting the desired shape with unrivaled precision. This subtractive manufacturing process is invaluable for producing automotive and medical components where every millimeter counts.

What sets CNC Turning apart is its versatility. Anco Precision Inc. employs advanced CNC turning centers that not only turn but also integrate milling capabilities. This amalgamation allows us to tackle complex geometries, crafting components that seamlessly blend form and function. I recall working on a project where we transformed a simple metal bar into an intricate aerospace part, thanks to our multi-axis CNC Turning capabilities.

Operational Advantages

In my experience at Anco Precision Inc., the advantages of CNC Turning are profound, transcending mere accuracy. The automated nature of CNC technology minimizes human error, ensuring each part is identical to the last–a critical aspect for industries such as aerospace and medical where consistency is non-negotiable. Moreover, the flexibility of CNC Turning machines enables us to easily switch between various materials and part designs, thus catering to diverse client needs.

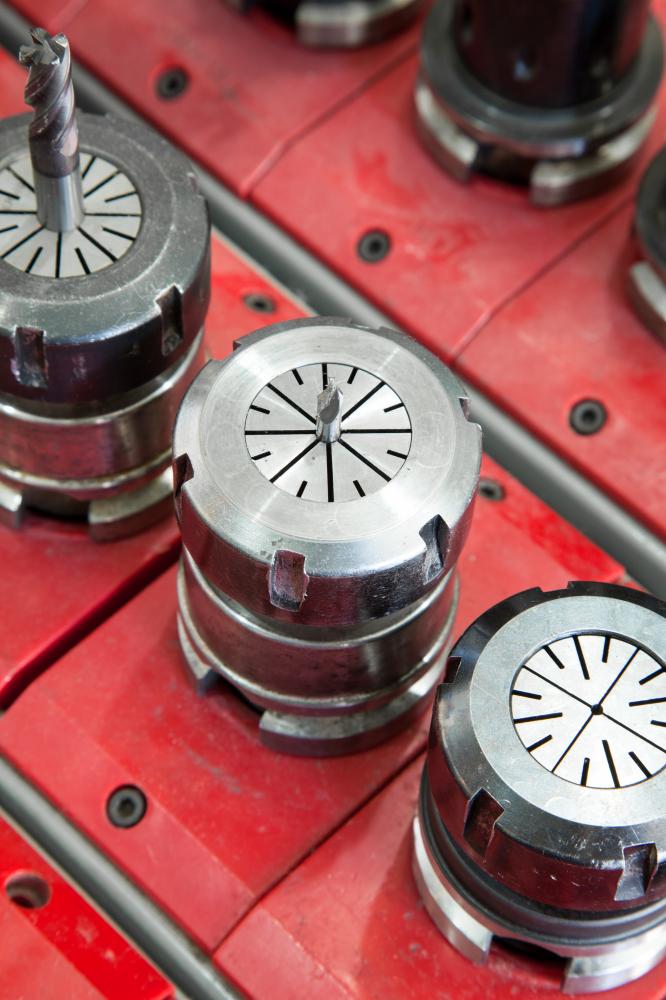

Additionally, safety is a paramount advantage. Traditional turning methods exposed operators to potential risks, but CNC Turning operates behind secure enclosures. Witnessing this firsthand, I can attest to how this advancement has reshaped our workspace, enhancing safety measures. This operational efficiency also translates into faster production times, allowing us to meet tight deadlines without compromising on quality. The seamless transition between tooling options further underscores the efficiency we achieve at Anco Precision, ensuring a swift response to pressing client demands.

At Anco Precision, the precision achieved through CNC Turning is undeniable, transforming raw materials into finely machined parts with speed and precision. Watching a raw metal bar evolve into a component ready for a marine engine, for instance, is a testament to the capabilities of CNC Turning when directed by skilled hands.

Personal Perspectives on CNC Turning

Having worked closely with CNC Turning at Anco Precision Inc., I’ve seen how it fosters innovation and opens doors to possibilities previously unattainable. Our ability to experiment with different materials and designs has been pivotal in developing customized solutions for our clients. These moments of innovation are often driven by the insights shared within our team, where seasoned machinists and engineers collaborate to push the boundaries of what CNC Turning can achieve.

Beyond the technical aspects, there’s a certain artistry involved in CNC Turning. Each piece tells a story of precision, dedication, and expertise. Every groove, thread, and angle is meticulously planned and executed, reflecting a commitment to excellence that we uphold at Anco Precision. It’s this blend of art and science that continues to inspire me and my colleagues as we tackle ambitious projects across industries, from automotive to aerospace.

At Anco Precision, we pride ourselves on our state-of-the-art CNC Turning capabilities and our ability to consistently deliver high-quality parts. This commitment to precision and quality has solidified our reputation as a trusted partner in the machining industry, allowing us to serve a diverse clientele with distinct needs.

The Role of CNC Turning in Modern Manufacturing

CNC Turning Services play an essential role in modern manufacturing, facilitating the production of high-precision parts across numerous industries. At Anco Precision Inc., we’ve seen firsthand how CNC turning transforms raw materials into intricately machined components that meet rigorous industry standards. Whether for the aerospace, automotive, or medical sectors, the precision of CNC Turning Services ensures each piece is manufactured with unparalleled accuracy, a critical factor when dealing with mission-critical components.

The craftsmanship involved in CNC Turning Services goes beyond just the technical execution. At Anco Precision Inc., every task is approached with an artisan mindset, treating each project as a testament to our expertise and dedication. Having worked with an array of materials, from aluminum and brass to specialized plastics, our team understands that the material’s characteristics often dictate the turning strategies employed. By tailoring our approach to the specific requirements of each project, we consistently deliver results that exceed expectations.

Advantages and Innovations in CNC Turning

One of the incredible advantages of CNC Turning Services is its adaptability in handling both small and large production runs. This flexibility is crucial for industries requiring rapid prototyping as well as mass production. As a family-owned business with 40 years of experience, Anco Precision Inc. has embraced the integration of state-of-the-art technology to enhance our CNC turning capabilities, ensuring high-quality output while maintaining competitive pricing. Our customers frequently praise our commitment to quick delivery times, a direct result of our efficient and innovative processes.

In addition to its efficiency, CNC Turning Services offer precise control over the manufacturing process, resulting in uniform products with minimal variation. This control is facilitated by advanced software that guides the turning operations, ensuring adherence to the tightest of tolerances. Additionally, CNC Turning allows for the production of complex geometries that would be challenging to achieve manually, pushing the boundaries of design possibilities for engineers and product developers. This capacity for complexity is often cited by our clients as a significant benefit of partnering with Anco Precision Inc., as it opens doors to new product innovations.

A distinctive feature of CNC Turning Services is its ability to combine both turning and milling operations, allowing for sophisticated machining capabilities. This integration is a game-changer for creating intricate parts that require both rotational and linear machining, enhancing the versatility of the production process. Anco Precision Inc. leverages this dual capability to meet the diverse needs of our clientele, ensuring that we can adapt to any design challenge presented.

Choosing the Right CNC Turning Partner

When selecting a partner for CNC Turning Services, it’s crucial to evaluate several factors to ensure the best fit for your project’s requirements. At Anco Precision Inc., we pride ourselves on not only the quality of our machined parts but also the customer experience we provide. Our clients range from individual inventors to large-scale industrial operations, each requiring a unique approach tailored to their specific needs. Maintaining open communication with our clients is key, assisting them in making informed decisions about their materials, designs, and overall project direction.

The strategic choice of a CNC turning partner should also consider the range of materials and secondary processes offered. Anco Precision Inc. provides an extensive list of materials including metals and engineered plastics, alongside secondary surface finishing options such as anodizing and polishing. This comprehensive service offering ensures that your project can be handled from start to finish under one roof, streamlining the production process and reducing lead times.

Ultimately, the decision to engage with a CNC Turning Services provider should rest on their track record of delivering precise, reliable, and innovative machining solutions. With over four decades of industry experience, Anco Precision Inc. has established itself as a leader in providing CNC Turning Services that meet and often exceed the exacting standards of our clients. Our commitment to precision and quality makes us a trusted partner in the ever-evolving landscape of manufacturing technology.

Understanding CNC Turning Florida: Key Aspects and Considerations

What makes CNC Turning services in Florida distinct from other regions in the U.S.?

Our CNC Turning services in Florida, especially at Anco Precision, are tailored to meet the diverse needs of local industries like marine, aerospace, and automotive, which are prevalent in this region. Florida’s industry mix demands high precision and quick turnaround, and our location in Deerfield Beach allows us to efficiently serve these sectors with our state-of-the-art equipment and experienced team. The local demand for innovation and customization has driven us to develop unique solutions that are highly appreciated by our clientele. If you’re considering CNC Turning services in Florida, think about the potential for developing tailored solutions that meet both local and national standards.

How do misconceptions about CNC Turning affect client expectations and how do we address them?

One common misconception is that CNC Turning is limited to simple cylindrical parts. In reality, our services at Anco Precision go beyond this, involving complex geometries and integrating milling operations for more intricate designs. We often take time during consultations to educate our clients, explaining that our capabilities extend to creating sophisticated parts for advanced applications in sectors like aerospace and medical. By addressing these misconceptions early, we set accurate expectations and ensure clients understand the full potential of what CNC Turning can offer. Are there any specific expectations you have about CNC Turning that you’d like clarified?

What role does CNC Turning play in the advancement of the aerospace industry in Florida?

In Florida, a state known for its aerospace activities, CNC Turning is crucial in delivering precision-engineered parts that meet stringent safety and performance standards. At Anco Precision, we manufacture components such as turbine blades and airframes with tight tolerances necessary for safe and efficient flight. Our experience with different materials and the ability to produce both prototypes and large-scale productions provide aerospace companies the reliability they need. As the aerospace industry evolves, the need for lightweight, high-performance components will only increase. How have you seen technology like CNC Turning impact your industry’s advancements?

How does Anco Precision ensure quality and precision in every CNC Turning project?

Quality is at the core of our operations at Anco Precision. Each CNC Turning project is handled by highly trained machinists who understand the subtleties of different materials and designs. We use state-of-the-art machinery that guarantees accuracy and consistency, and our commitment to continuous improvement keeps us ahead in adopting the latest machining technologies. Quality assurance measures, such as regular inspections and testing, ensure that every part meets our high standards before delivery. If quality and precision are your top priorities, why not consider working with a CNC Turning partner who values the same?

What are the operational advantages of CNC Turning over traditional machining methods?

CNC Turning offers remarkable advantages over traditional machining, particularly in terms of efficiency, precision, and safety. For example, our automated CNC systems at Anco Precision minimize human error and allow for high-volume production with uniform quality. The ability to quickly switch between projects and materials is another operational advantage, enhancing flexibility and responsiveness to client demands. Moreover, CNC Turning’s precision reduces material waste, contributing to cost efficiency and sustainability. Have you experienced the benefits of CNC Turning in streamlining your production processes?

Why is choosing the right CNC Turning partner critical for project success?

Selecting the right CNC Turning partner, such as Anco Precision, ensures that your project’s specific needs are met with professionalism and expertise. Our extensive experience across various industries allows us to offer insightful guidance on design and material choices. We provide comprehensive services from initial concept to final product, incorporating any required secondary processes. Our commitment to strong communication ensures you are kept informed and confident in the project’s progress. When choosing a partner, consider their track record, industry experience, and the range of services they offer. What factors are most important to you when selecting a CNC Turning partner?

Resources

- NASA – The official homepage of the National Aeronautics and Space Administration, providing information on space exploration, research, and innovation.

- American Society for Engineering Education – The website of the ASEE, offering resources and support for engineering educators and students.

- National Institute of Standards and Technology – The NIST website, providing information on standards, technology, and research to support industry and innovation.