Exploring the World of CNC Milling

CNC Milling Services have revolutionized the manufacturing industry, providing precision and efficiency like never before. At the heart of this transformation is Anco Precision Inc., a family-owned CNC machine shop located in Deerfield Beach, FL. With over four decades of experience, they have mastered the art of CNC milling, catering to a variety of industries such as marine, automotive, medical, and aerospace. Their dedication to precision ensures that every customer’s needs are met with exceptional attention to detail.

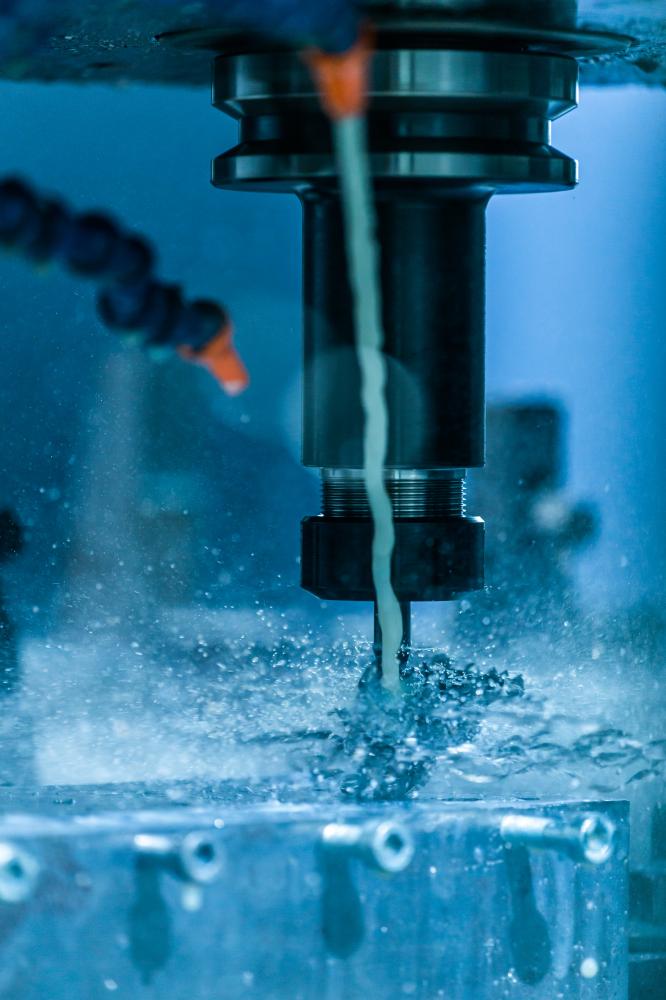

One of the standout features of CNC milling, especially at Anco Precision, is the ability to fabricate complex 3D shapes using computer numerical control. This process involves intricate tool movements that can create everything from simple components to complex geometrical structures. Machinists at Anco Precision undergo extensive training to operate state-of-the-art equipment, resulting in products that meet the highest standards of quality.

The Diverse Applications of CNC Milling

The applications of CNC Milling Services are as diverse as they are significant. Anco Precision Inc. specializes in manufacturing custom car parts, medical instruments, and even components for aircraft and watercraft. Such versatility speaks to the adaptability of CNC milling in addressing varied industrial needs. Their ability to serve sectors ranging from government agencies to universities highlights their expansive reach and expertise.

The rapid prototyping capabilities offered by CNC milling play a pivotal role in product development cycles. Anco Precision ensures quick turnaround times, which is crucial for industries operating on tight schedules. The instant quoting service provided by their online platform streamlines the process even further, allowing clients to initiate projects with ease and efficiency.

In the automotive industry, CNC milling is often used to manufacture engine components and gearbox casings, where precision is paramount. The aerospace sector benefits from the production of high-strength, lightweight parts, while the medical industry relies on CNC-milled instruments for their accuracy and reliability.

Personal Experiences and Insights from Anco Precision

Working at Anco Precision offers unparalleled insights into the world of CNC Milling Services. Employees often share anecdotes about complex projects that posed unique challenges yet led to significant learning and growth. One machinist recalled a particularly challenging project involving prototype enclosures for electronics that required tight tolerances and exceptional finish quality. Their success in this venture was attributed to a combination of advanced machinery and the collective expertise of the team.

Regular clients of Anco Precision frequently commend the organization’s commitment to maintaining a seamless balance between cost-effectiveness and high-quality output. By utilizing CNC milling, they manage to keep production costs low, while ensuring that the products manufactured meet the stringent standards set by their diverse clientele.

The family-owned aspect of Anco Precision adds a personalized touch to their services. This is reflected in their approach to customer service, where every inquiry and quote request is handled with a level of care and attention rare in the industry. Their dedication has not gone unnoticed, with numerous testimonials praising their professionalism and consistent quality.

Innovative Aspects and Future Trends of CNC Milling

The landscape of CNC Milling Services is continually evolving, with technological advancements pushing boundaries further. Anco Precision is at the forefront of these changes, constantly upgrading their machinery and techniques to adapt to new industry standards. Innovations such as multi-axis CNC machining allow for even greater complexity in parts, opening new avenues for applications.

Looking to the future, the integration of smart manufacturing processes and artificial intelligence in CNC milling could further enhance production capabilities. Such advancements promise to streamline workflows, reduce waste, and improve overall efficiency. Anco Precision is committed to staying ahead of the curve, ensuring they continue to deliver cutting-edge solutions to their clients.

Precision Engineering in CNC Milling

CNC Milling is a cornerstone of modern manufacturing, renowned for its precision and ability to create intricate designs with high accuracy. At Anco Precision Inc., the use of state-of-the-art CNC milling machines allows for the meticulous crafting of parts required in industries ranging from aerospace to medical. With over 40 years in the industry, the machinists at Anco have honed their skills to ensure that every part meets exact specifications, demonstrating a commitment to quality that their clients expect.

One unique aspect of CNC Milling is its versatility. The process can accommodate a wide variety of materials, including metals, plastics, and composites. Anco Precision Inc. leverages this flexibility to serve diverse sectors, offering solutions for custom car parts, optical devices, and much more. The technology behind CNC Milling is constantly evolving, and Anco stays ahead by investing in training and innovative technology, ensuring that they meet the most demanding production requirements.

CNC Milling Processes and Techniques

The CNC Milling process involves several essential stages, beginning with the creation of a CAD model. At Anco Precision Inc., machinists use advanced CAD software to design precise components that fulfill specific client requirements. This model is then transformed into a language the milling machine understands, known as G-code, which dictates the toolpaths and machining processes.

During machining, the material block is secured on the machine bed, and cutting tools remove material based on the programmed instructions. Anco’s machinists are adept at setting up and operating these machines to maintain the tight tolerances required for critical applications. The type of machine used can vary, including 3-axis, 4-axis, and 5-axis machines, each offering different advantages in terms of complexity and capability.

Importance of CNC Milling in Varied Industries

Within the aerospace industry, precision is paramount, and CNC Milling plays a crucial role in producing reliable components such as landing gear and airframe elements. Anco Precision Inc. contributes to the aerospace field by delivering parts that adhere to strict safety and performance standards. Their reputation for precision extends to the medical sector, where components like surgical instruments must meet stringent quality controls.

Additionally, CNC Milling is indispensable in the automotive industry, where it is used to manufacture engine components and custom parts. Anco Precision Inc. offers competitive pricing and quick turnaround times, making them a preferred partner for businesses seeking reliable manufacturing solutions. Their ability to provide instant quotes through an online platform further streamlines the production process for clients.

For Anco Precision Inc., customer satisfaction is as crucial as the milling process itself. By combining technical expertise and a customer-centric approach, they maintain strong relationships with their clients, ensuring that each project is completed to the highest standards. Whether it’s a university needing prototype development or a government agency requiring specialized parts, Anco’s dedication to CNC Milling ensures exceptional results.

The Essential Role of CNC Milling Florida in Multiple Industries

The realm of CNC Milling Florida is immensely diverse, touching numerous sectors from automotive to aerospace. Anco Precision Inc., a family-owned business in Deerfield Beach, FL, brings over 40 years of experience to the table, carving a niche for itself in the industry. Their unwavering commitment to precision ensures that every component they manufacture delivers on quality, no matter the complexity. Whether it’s producing custom parts for a classic car or crafting intricate components for spacecraft, the applications of CNC Milling Florida are vast. The team’s dedication to perfection is not just an operational mantra but a promise to their clientele, reinforced by the positive testimonials they receive.

In the bustling CNC Milling Florida landscape, the demands of the marine and medical sectors are just as significant. The marine industry, for example, requires precision-engineered components to withstand challenging conditions at sea. Anco Precision excels in this domain, ensuring that every piece not only meets but exceeds industry standards. Similarly, the medical field relies on precise parts for critical instruments, where even a minor deviation can have significant consequences. Anco’s expertise and meticulous attention to detail make them a preferred partner for many healthcare providers.

Innovations in CNC Services at Anco Precision

A key differentiator for Anco Precision in the CNC Milling Florida scene is their embrace of cutting-edge technology. By integrating the latest advancements into their processes, they remain at the forefront of innovation. The use of state-of-the-art CNC machines facilitates rapid prototyping, allowing them to bring ideas to reality swiftly. This capacity accelerates the development process, bridging the gap between concept and production.

Their adoption of advanced techniques also plays a pivotal role in the aviation sector, where precision and reliability are non-negotiable. Parts for aircraft require stringent tolerances and immaculate finishes, and Anco’s facility is equipped to meet these demands. By leveraging their expertise in CNC milling and turning, they provide essential components for aerospace applications, contributing to the success of numerous projects.

Moreover, Anco Precision’s dedication to quality extends beyond just technology. Their rigorous training for machinists ensures that the human element complements their technological capabilities. This synergy between skilled professionals and high-tech equipment results in a formidable output that has positioned Anco as a leader in CNC Milling Florida.

Customer-Centric Focus and Diverse Services

Customer satisfaction is at the heart of Anco Precision’s operations. Their approach to CNC Milling Florida is rooted in responsiveness and custom solutions, tailored to individual project needs. With a streamlined process for obtaining quotes, clients can easily plan their projects with financial clarity. By prioritizing open communication and flexibility, Anco ensures that their customers are always informed and satisfied with the progress and results.

Their comprehensive service offerings cater to various industrial requirements, be it automotive, medical, or aerospace. Anco’s capabilities in CNC turning and screw machining complement their milling services, enabling them to handle a wide array of manufacturing demands. This versatile approach to CNC Milling Florida demonstrates their commitment to being a one-stop solution for diverse machining needs.

Ultimately, Anco Precision’s standing in the CNC Milling Florida market is a testament to their unwavering dedication to quality, innovation, and customer satisfaction. Their continued focus on excellence ensures that they remain a trusted partner in the machining industry for years to come.

What are the key advantages of CNC Milling Services, especially in a family-owned setup like Anco Precision?

At Anco Precision, we truly believe that one of the standout benefits of CNC Milling Services is the precision and efficiency it offers. Being a family-owned business allows us to maintain a personal touch in our operations, which is reflected in our attention to detail and commitment to quality. I recall a project where a client needed intricate components for a medical device. Our state-of-the-art machinery, coupled with our team’s expertise, enabled us to deliver parts that met the highest industry standards. The ability to produce complex 3D shapes efficiently through computer numerical control is another significant advantage. Moreover, the family-owned aspect means we handle each project with care, ensuring every customer feels valued. Have you ever considered how this personal touch might affect the quality and reliability of the products you use?

Can you address some common misconceptions about CNC Milling and how Anco Precision navigates them?

One common misconception is that CNC Milling is only suited for large-scale production. However, at Anco Precision, we’ve found that it’s incredibly versatile, suitable for both small batches and mass production. Another myth is that CNC Milling offers limited material options. In reality, we work with metals, plastics, and composites, adapting to the unique needs of each sector, from automotive to medical. Also, many believe that such precision comes with high costs. I remember a client who was initially concerned about expenses for custom automotive parts but was pleasantly surprised at our competitive pricing, thanks to our efficient processes and rapid prototyping capabilities. Have you encountered any misconceptions about CNC Milling in your own experiences or industry observations?

How is CNC Milling in Florida, particularly at Anco Precision, contributing to multiple industries?

Operating in Florida, Anco Precision has carved its niche by supporting diverse industries such as marine, aerospace, and medical. Our proximity to these sectors allows us to provide customized solutions tailored to specific regional needs. For instance, the marine industry here requires parts that can withstand harsh conditions, and we’ve excelled in delivering components that exceed these standards. I remember collaborating on a project for a local aerospace company where precision was non-negotiable, and our team delivered components that were both high-strength and lightweight. By leveraging our extensive experience and state-of-the-art technology, we’re proud to contribute to Florida’s robust manufacturing landscape. How might regional manufacturing differences impact the quality and innovation in your own field?

What are the future trends in CNC Milling Services, and how does Anco Precision plan to adapt?

Looking ahead, the integration of smart manufacturing and AI in CNC Milling is a trend we’re particularly excited about at Anco Precision. This will enhance efficiencies, reduce waste, and streamline workflows. We are continuously upgrading our machinery and training our staff to stay at the cutting edge of these innovations. For example, multi-axis CNC machining is opening new possibilities for complexity and precision in part manufacturing. I often think back to when we integrated our first 5-axis machine; it revolutionized our capabilities and expanded our service offerings significantly. As we move forward, we’re committed to adopting these future trends to continue providing top-notch solutions to our clients. What future advancements do you think could have the most transformative impact on your industry or daily life?

Resources

- National Institute of Standards and Technology – The NIST website offers valuable information on manufacturing standards and technologies.

- NASA – Explore NASA’s website to learn about the aerospace industry and its advanced technologies.

- National Institutes of Health – Visit the NIH website for insights into medical advancements and precision engineering.

- Federal Aviation Administration – Learn more about aviation regulations and industry standards from the FAA website.

- Automotive World – Delve into the automotive industry and its manufacturing processes on the Automotive World website.