Evolution of Aluminum Machining Florida

Aluminum machining in Florida has evolved significantly over the past few decades. Today, businesses across the state are leveraging cutting-edge technologies to enhance precision and efficiency in manufacturing. At the forefront of this evolution is Anco Precision Inc., a family-owned CNC machine shop that has been serving Florida for over four decades. Their dedication to high-quality machining has earned them a stellar reputation across a range of industries, from automotive to aerospace.

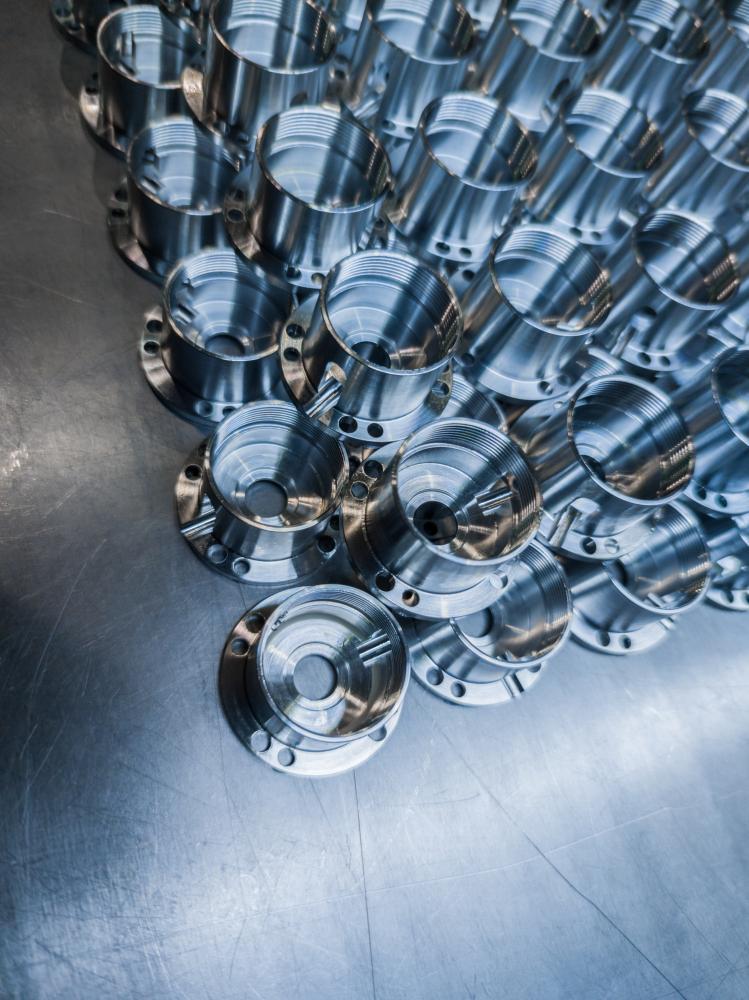

Advanced CNC technology has revolutionized the way aluminum machining is carried out in Florida. This technology allows machinists to create complex parts with unparalleled precision. Anco Precision Inc., for instance, uses state-of-the-art equipment to ensure that every product meets the highest standards of accuracy. This level of precision is crucial in industries such as medical and aerospace, where even the smallest error can have significant consequences.

The adaptability of aluminum as a material is also a major factor in its widespread use in Florida’s machining industry. Its lightweight nature, corrosion resistance, and excellent thermal conductivity make it ideal for a variety of applications. Companies like Anco Precision leverage these properties to produce durable, high-performance components that meet the diverse needs of their clients.

Benefits of Aluminum Machining Florida

Aluminum machining offers several benefits that make it an attractive choice for manufacturers in Florida. One of the most significant advantages is its cost-effectiveness. Aluminum is an abundant material, and its lightweight nature makes it easier and cheaper to work with compared to other metals like steel or copper. This economic efficiency is a boon for businesses looking to minimize expenses without compromising on quality.

Another key benefit is the material’s recyclability. Aluminum can be easily recycled without losing its properties, which aligns well with the growing emphasis on sustainability in modern manufacturing. Companies like Anco Precision are increasingly using recycled aluminum in their processes, helping reduce the industry’s carbon footprint while maintaining high standards of production.

Advantages of Aluminum Machining

- Lightweight and durable

- Cost-effective and abundant

- Recyclable and sustainable

- Resistant to corrosion

Moreover, aluminum’s excellent thermal and electrical conductivity make it a preferred material for industries such as electronics and automotive. Its ability to dissipate heat efficiently ensures optimal performance in applications like HVAC units and electrical components.

Precision and Quality in Aluminum Machining Florida

At the core of Anco Precision’s success in aluminum machining Florida is their unwavering commitment to precision and quality. The company employs highly skilled machinists who undergo extensive training to operate advanced CNC machinery. This expertise enables them to produce complex components with exacting tolerances, ensuring that every part meets the client’s specifications.

Anco Precision’s dedication to quality is reflected in their rigorous quality control measures. Each component is meticulously inspected throughout the production process to ensure it meets the highest standards. This attention to detail has made them a trusted partner for clients across various industries, from government agencies to tech startups.

Customer satisfaction is another cornerstone of Anco Precision’s operations. The company prides itself on offering outstanding service, quick turnaround times, and competitive pricing. Testimonials from satisfied customers highlight the professionalism and reliability of their services, making Anco Precision a go-to choice for both prototype and production parts manufacturing in Florida.

Innovative Solutions in Aluminum Machining Florida

Anco Precision Inc. is not just about manufacturing; they are committed to providing innovative solutions that address the unique challenges faced by their clients. By offering services such as rapid prototyping and screw machining, they enable businesses to bring their ideas to life quickly and efficiently. This agility is crucial in today’s fast-paced market where time-to-market can be a critical factor in a product’s success.

Additionally, Anco Precision’s use of instant quotes through their online machine shop simplifies the process for clients, making it easier for them to get their projects started. This user-friendly approach is particularly beneficial for small businesses and entrepreneurs who need to manage their resources effectively.

By constantly exploring new technologies and methods, Anco Precision continues to stay ahead in the field of aluminum machining Florida. This commitment to innovation and excellence ensures they remain a vital resource for businesses looking to leverage the benefits of aluminum machining in the Sunshine State.

Exploring the Fascination with Aluminum

Aluminum Machining offers a unique combination of properties that make it particularly appealing in a variety of industries. Its exceptional strength-to-weight ratio, combined with its corrosion resistance and recyclability, positions it as a top choice for many manufacturers. Anco Precision Inc., a leader in CNC machining services, often highlights aluminum’s adaptability, making it a favorite for projects spanning automotive, aerospace, and electronic sectors.

In the pursuit of “lightweighting,” aluminum consistently replaces heavier metals like steel, enhancing energy efficiency without compromising strength. During my tenure at Anco Precision, I witnessed how aluminum’s non-toxic, sleek surface contributed to innovative solutions in product design. Its application in producing components for marine and medical sectors further attests to its versatility.

Despite its myriad of advantages, aluminum’s machinability is perhaps its most compelling feature. It’s easily shaped and formed, facilitating the creation of complex parts with precision. Imagine transforming a solid block into detailed engine parts with efficiency and minimal waste. This forms the backbone of operations at Anco Precision Inc., where CNC milling and turning make such processes feasible.

Mastering the Art of Machining Processes

CNC Milling and Turning

CNC milling and turning are two of the fundamental processes involved in Aluminum Machining. At Anco Precision Inc., milling machines carve intricate designs out of aluminum blocks, rendering them ready for various applications. The precision of computer numerical control (CNC) delivers repeatable accuracy, a crucial requirement in the high-stakes world of aerospace manufacturing.

Advanced Cutting Techniques

Beyond milling and turning, Anco Precision employs advanced cutting techniques like laser, plasma, and water jet cutting. These methods cater to diverse project requirements and material thicknesses, ensuring that parts withstand the demands of their intended use.

Among these methods, water jet cutting stands out due to its ability to slice through aluminum without inducing thermal stress. This technique, combined with CNC technology, enables the creation of sophisticated parts without altering the material’s inherent properties. Such innovations are pivotal, especially in the medical field where non-deformation is critical.

Plasma and laser cutters add another dimension to Anco Precision’s operations. With capabilities to handle thin sheets with unrivaled precision, these machines are indispensable in the production of electronic cases and housings. The reduced energy consumption of laser cutting also aligns with growing sustainability practices in the industry.

Aluminum vs. Steel: The Ongoing Debate

While aluminum is celebrated for its advantages in machining, steel frequently presents itself as a formidable contender. Anco Precision Inc. often navigates this decision-making terrain, balancing the strengths of each material. Aluminum’s weight efficiency typically trumps steel when it comes to applications requiring mobility, yet steel’s durability cannot be overlooked.

The cost factor often sways the decision towards aluminum, particularly where budget constraints are in play. Aluminum Machining not only offers cost savings through material efficiency but also by lowering machining cycle times due to its quicker cooling properties. This makes it particularly attractive for projects with tight timelines or budgetary limitations.

Manufacturers must weigh multiple factors such as corrosion resistance and environmental exposure when choosing between the two. While stainless steel boasts superior resistance, aluminum eliminates the need for heavy protective coatings common with other steels. At Anco Precision, this often results in streamlined production processes and reduced material handling complexities.

Ultimately, the choice between aluminum and steel extends beyond surface-level considerations. It involves a strategic evaluation of project goals, timelines, and environmental impacts. The insights and experiences gained at Anco Precision Inc. underscore the nuanced decision-making involved in selecting the right material for CNC machining endeavors.

Advantages of Aluminum CNC Machining

Aluminum CNC Machining offers a plethora of benefits that make it a favored choice among manufacturers across various industries. One of the most significant advantages is its exceptional strength-to-weight ratio, which enhances performance without adding unnecessary bulk. This feature is particularly crucial in aerospace and automotive sectors, where every gram counts.

Anco Precision Inc., a specialist in CNC machining services, has leveraged these advantages to serve clients in the marine, medical, and aerospace industries with remarkable efficiency. Their state-of-the-art machinery ensures that each product is crafted with unbeatable precision, catering to detailed specifications across diverse applications. The non-magnetic properties and excellent thermal conductivity of aluminum further enhance its versatility in different settings.

The environmental impact is another noteworthy aspect of choosing aluminum. The metal’s ability to be recycled without losing its properties means manufacturers can significantly reduce their carbon footprint. Anco Precision is committed to sustainable practices, integrating recycled materials into their processes whenever possible, thus promoting both ecological responsibility and economic savings.

CNC Machining Processes and Techniques

The journey of transforming aluminum into intricate components begins with a variety of CNC machining processes. Milling and turning are predominantly used to achieve desired shapes and dimensions. Aluminum’s machinability allows these processes to be executed swiftly, reducing production time and enhancing efficiency at Anco Precision. The smooth finish and meticulous detail possible with CNC milling ensure high-quality outcomes every time.

Several other techniques complement milling and turning, such as laser and waterjet cutting, providing an array of options to precision-tune any project. Anco Precision’s machinists, equipped with extensive training, seamlessly navigate between these techniques to suit client requirements. With an emphasis on precision, the shop crafts everything from custom car parts to crucial medical instruments with unmatched detail.

Having hands-on experience with CNC turning, Anco Precision’s team efficiently manages projects featuring both complex and simple geometries. The rapid prototyping capabilities further support design innovations and expedite the transition from concept to reality, making them an invaluable partner for product developers and designers.

The ability to receive instant quotes through their online platform exemplifies Anco Precision’s dedication to client convenience. By submitting design files, customers can access immediate and detailed machining estimates, streamlining project initiation and ensuring transparency from the onset.

Application of Aluminum CNC Machining in Diverse Industries

Aluminum CNC Machining at Anco Precision is not limited to one sector; it stretches across a multitude of industries, each with unique demands and expectations. In aerospace, the lightweight yet robust characteristics of aluminum make it essential for manufacturing aircraft components, where safety and efficiency are paramount. The marine industry also benefits from aluminum’s corrosion resistance, ensuring longevity in harsh, saltwater environments.

In the medical field, the precision required for instruments is non-negotiable. Anco Precision harnesses the finesse of aluminum CNC Machining to craft medical devices with exacting standards. The biocompatibility of certain aluminum alloys further supports its suitability in medical applications, allowing for safe and reliable use in patient care.

The automotive industry is another arena where aluminum shines. As manufacturers seek ways to improve fuel efficiency and performance, aluminum’s lightweight nature plays a crucial role. Components like engine blocks and body panels are increasingly being machined from aluminum, showcasing its versatility and strength.

Aluminum CNC Machining also extends to electronics and telecommunications, where heat dissipation and durability are critical. Anco Precision’s offerings, from enclosures to electronic device components, demonstrate the adaptability of aluminum to meet specific technological challenges.

How has the evolution of aluminum machining impacted the industry in Florida?

The evolution of aluminum machining has significantly transformed various industries in Florida by enhancing precision and efficiency. At Anco Precision Inc., we’ve seen firsthand how cutting-edge CNC technology allows us to produce complex parts with remarkable accuracy. This advancement is particularly crucial in industries like aerospace and medical, where even the slightest deviation can have serious repercussions. We’ve been able to meet the high demands of these sectors while maintaining cost-effectiveness due to aluminum’s abundance and versatility.

Moreover, Florida’s emphasis on innovation has pushed our company to adopt new techniques and refine our processes continually. The impact has been profound, allowing us to offer services such as rapid prototyping and screw machining, which cater to the diverse needs of our clients. This evolution not only drives our business forward but also supports the broader commitment to sustainability and efficiency across the state.

What are some ways you believe technology will continue to revolutionize aluminum machining in the coming years?

What are common misconceptions about aluminum machining?

One common misconception about aluminum machining is that it’s a compromise compared to more traditional materials like steel. However, I can assure you that aluminum offers a unique strength-to-weight ratio that makes it ideal for applications demanding mobility and efficiency. Its recyclability and corrosion resistance further enhance its appeal. At Anco Precision, we’ve utilized aluminum in projects across marine, medical, and automotive industries, proving its versatility and reliability.

Another misconception is that aluminum machining is less precise. On the contrary, our state-of-the-art CNC equipment is capable of achieving exacting tolerances needed for high-stakes fields. The machinability of aluminum allows us to deliver high-quality outcomes efficiently. This makes it a favorite among industries focused on innovation and speed.

Have you encountered any other misconceptions that you’d like to discuss or clear up?

How does aluminum CNC machining enhance product quality?

Aluminum CNC machining significantly enhances product quality by offering precise control over the manufacturing process. At Anco Precision, our CNC machines can produce parts with exceptional accuracy, ensuring that each component meets specified requirements. This precision is vital in industries like aerospace and medical, where the margin for error is minimal. Aluminum’s properties, such as its excellent thermal conductivity and machinability, further aid in crafting parts that are both durable and efficient.

Our clients particularly appreciate the rapid prototyping capabilities that CNC machining of aluminum offers. This allows for quick iterations and fast adaptation to design changes, ensuring products are perfected before mass production. Additionally, the use of recycled aluminum in our processes aligns with growing sustainability practices, reducing our environmental footprint without compromising quality.

What are your thoughts on the role of CNC machining in creating more sustainable manufacturing practices?

How do innovative solutions in aluminum machining benefit small businesses?

Innovative solutions in aluminum machining can greatly benefit small businesses by streamlining production processes and reducing costs. At Anco Precision, our use of instant quotes through an online machine shop is designed to support small enterprises by making the ordering process straightforward and efficient. This service allows businesses to plan and allocate resources effectively, ensuring they receive high-quality components without unnecessary delays.

The rapid prototyping services we offer also empower small businesses to innovate quickly. By bringing ideas to life faster, they can compete more effectively in a fast-paced market. The agility provided by such solutions helps small businesses adapt to changing demands and seize new opportunities without the burden of extensive overhead.

What other innovative solutions do you think could help small businesses thrive in manufacturing?

What are the key differences between aluminum and steel in machining?

When comparing aluminum and steel in machining, several key differences come to the forefront. Aluminum is notably lighter than steel, making it the preferred choice for applications where weight is a critical factor, such as in the aerospace and automotive industries. Its excellent thermal conductivity and corrosion resistance further make it suitable for diverse environments. At Anco Precision, we’ve optimized our processes to leverage these advantages, offering high-quality components that require less energy to machine.

Steel, on the other hand, is renowned for its strength and durability. It’s often chosen for projects where these attributes are paramount, although it typically requires more extensive protective coatings and has a longer machining cycle compared to aluminum. Our experience at Anco Precision has shown that while both materials have their merits, the choice often boils down to specific project requirements and constraints.

Have you faced challenges in deciding between aluminum and steel for your projects, and if so, what criteria do you use to make your decisions?

Resources

- National Institute of Standards and Technology (NIST) – NIST is a leading scientific research organization that provides valuable resources on materials, manufacturing, and technology.

- Environmental Protection Agency (EPA) – The EPA offers information on sustainability, recycling, and environmental practices related to aluminum machining and manufacturing.

- NASA – NASA’s website provides insights into the aerospace industry and the use of aluminum in spacecraft and aircraft manufacturing.

- National Institutes of Health (NIH) – The NIH offers information on medical applications of aluminum and CNC machining in the healthcare industry.

- Smithsonian Magazine – Smithsonian Magazine explores the history and significance of aluminum in various industries, shedding light on its importance in modern manufacturing processes.