Redefining Precision in Aerospace Manufacturing

In the heart of Deerfield Beach, FL, lies Anco Precision Inc., a family-owned powerhouse that gives new meaning to precision in the world of manufacturing. As an Aerospace Machine Shop, Anco Precision is not just about producing parts; it’s about engineering excellence into every piece they craft. Drawing from over 40 years of experience, they’ve set a standard that speaks volumes in the aerospace industry–be it for custom car parts or delicate medical instruments. Their state-of-the-art CNC milling and turning capabilities ensure every project, regardless of its complexity, meets the high-caliber specifications demanded by aerospace applications.

The affable team at Anco Precision goes above and beyond to include their clients in the manufacturing journey. Through personalized consultations and the use of cutting-edge technology, each client can visualize their project from inception to realization. This collaborative ethos has cemented Anco Precision’s reputation as a trusted Aerospace Machine Shop, where customer satisfaction and precision collide.

Cutting-Edge Technology and Innovation

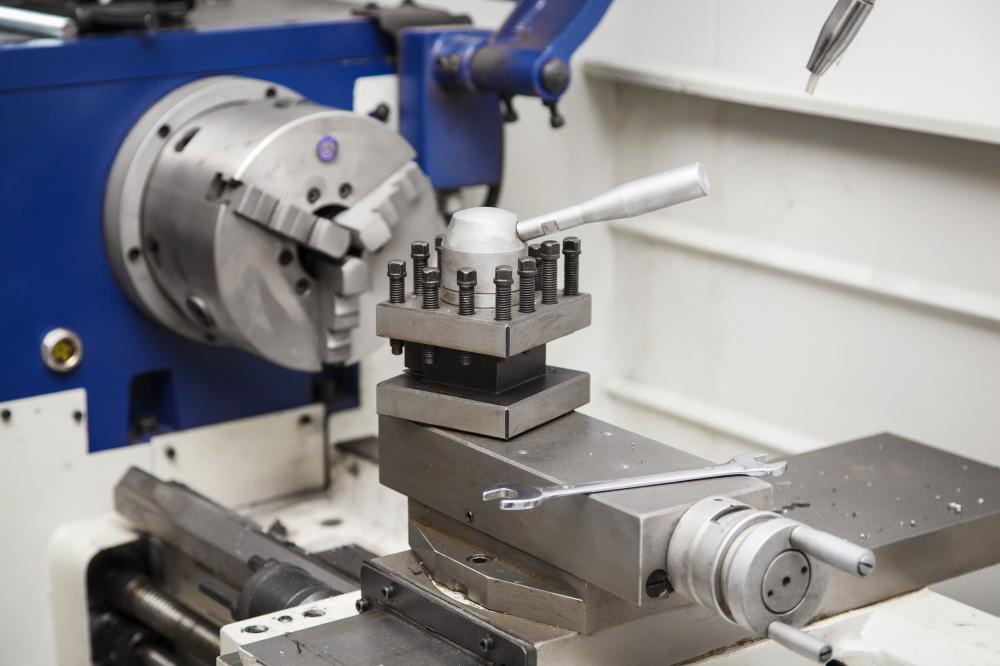

Innovation is the cornerstone of Anco Precision’s operations. Their use of advanced CNC machinery, paired with skilled machinists, transforms raw materials into intricate components ready to take flight in aerospace missions. Whether it’s CNC turning or screw machining, Anco Precision employs technologies that push the boundaries of what is possible in an Aerospace Machine Shop. Each machine in their fleet is a testament to their commitment to precision and quality.

But what truly sets Anco Precision apart is their endeavor to stay ahead of industry trends by continuously investing in the latest technology. This forward-thinking approach ensures that they not only meet present demands but also anticipate the future needs of the aerospace industry. By integrating rapid prototyping into their services, Anco Precision enables clients to fine-tune designs swiftly, reducing time-to-market while maintaining high-quality output.

From robotic assemblies to optical devices, the team navigates diverse projects with finesse, supported by comprehensive training that equips them to handle even the most challenging tasks. Anco Precision’s workshop is more than just an Aerospace Machine Shop; it is a hub of innovation and expertise where every component is crafted with precision and care.

Services That Fly High

Collaborative Engineering Solutions

While Anco Precision excels in manufacturing, they also bring collaborative engineering solutions. Their machinists work closely with clients, ensuring designs are optimized for production without compromising on quality. This partnership fosters innovation and helps streamline the fabrication process, solidifying Anco Precision’s role as an invaluable partner in aerospace engineering.

Commitment to Customer Satisfaction

With a clientele ranging from government agencies to universities and individual inventors, Anco Precision’s customer service is second to none. Clients appreciate the online instant quote service, simplifying the process and accelerating project timelines. This convenience is yet another feather in their cap, demonstrating their dedication to fulfilling customer needs efficiently and effectively.

Unyielding Dedication to Quality

Quality is an unwavering priority at Anco Precision. Each piece undergoes meticulous inspection before it leaves the workshop floor, ensuring it meets and often exceeds industry standards. This dedication to excellence is why Anco Precision remains a sought-after Aerospace Machine Shop, where every part tells a story of precision and craftsmanship.

An Insider Perspective

Having collaborated on numerous aerospace projects, Anco Precision knows the critical role an Aerospace Machine Shop plays in mission success. Their hands-on approach and attention to detail have earned them accolades from satisfied customers who value their expertise and dedication. One satisfied client remarked, “Anco’s precision and timely delivery make them an indispensable ally in any aerospace venture.”

For those venturing into aerospace manufacturing, Anco Precision offers not just services, but a partnership characterized by innovation, precision, and trust. With their fingers on the pulse of technological advancements and an unwavering commitment to quality, Anco Precision continues to elevate the standards of what an Aerospace Machine Shop can deliver, crafting components that are as reliable as the team who builds them.

Precision in Motion: CNC Machining at Anco Precision Inc.

At Anco Precision Inc., Aerospace Machining becomes an art form, as we meticulously sculpt intricate components that define the aerospace sector’s cutting-edge. Our precision CNC machines, operated by master machinists, create components with dimensions so exact, they could dance through the sky. With decades of experience under our belt, we understand that every component must not only meet specifications but also exceed expectations. The aerospace industry demands nothing less–it requires unwavering precision and consistency.

The skilled team at Anco Precision, based in the heart of Deerfield Beach, FL, harnesses their years of expertise with state-of-the-art technology to tackle even the most ambitious aerospace projects. Whether crafting lightweight parts for optimal aerodynamics or robust components for withstanding immense stresses, our engineers and machinists blend skill with innovation to deliver unparalleled solutions. Our commitment to detail and quality ensures that every piece of machinery that leaves our facility is ready to soar to new heights.

Materials and Methods: A Diverse Approach

Exploring Material Choices

In Aerospace Machining, the choice of materials is as pivotal as the machining process itself. At Anco Precision, we work with a variety of materials, from sturdy aluminum alloys to high-performance polymers, each selected for its distinct properties. Aluminum, with its exceptional strength-to-weight ratio, is often the trusted choice for airframes and structural components, while titanium, known for its resilience, is preferred for parts subjected to high temperatures and stress.

Advanced Machining Techniques

Our repertoire of machining techniques is extensive, a necessity to cater to the diverse needs of the aerospace industry. With CNC milling and turning at the forefront, we specialize in creating parts with complex geometries and tight tolerances. The 5-axis CNC machining process allows us to work on intricate designs, reducing setup time and improving surface finishes. Our expertise in screw machining and rapid prototyping further enables us to handle projects that demand both speed and precision.

Client Collaborations: Building Trust Through Excellence

Meeting the demands of Aerospace Machining requires more than just technical expertise; it requires a partnership mindset. At Anco Precision, we’ve built enduring relationships with clients by offering not only high-quality products but also invaluable insights and collaboration throughout the project lifecycle. Our clients–ranging from aerospace giants to innovative startups–rely on us not just for our machining prowess, but for our willingness to understand and adapt to their unique visions and requirements.

We take pride in our ability to deliver precise components swiftly, ensuring that our clients can maintain their project timelines without compromising on quality. As we strive to continuously improve, our clients’ feedback becomes a vital component of our growth, guiding us in refining our processes and expanding our capabilities. This collaborative ethos has cemented Anco Precision’s reputation as a reliable partner in the intricate dance of Aerospace Machining.

Efficiency Through Instant Quotes

Streamlining the project initiation process, Anco Precision offers instant online quotes, a service that empowers clients to jumpstart their projects efficiently. By simply submitting a drawing file to our online platform, clients can receive detailed quotes immediately, allowing them to make informed decisions quickly. This approach not only enhances our service efficiency but also aligns with our commitment to support our clients’ demands for agility and precision.

Embracing the Future: Innovation and Sustainability

As pioneers in Aerospace Machining, Anco Precision is always forward-looking, keen to incorporate the latest innovations in our processes. Our embrace of hybrid manufacturing techniques–merging traditional machining with digital advancements–keeps us at the forefront of industry trends. We adopt cutting-edge approaches like integrating additive manufacturing to enhance the efficiency and quality of the components we produce.

Moreover, our commitment to sustainability is ingrained in every facet of our operation. By optimizing material usage and reducing waste, we endeavor to contribute positively to the industry’s environmental footprint. Our quest for innovation doesn’t just stop at the technical level; it extends to fostering a culture where sustainable practices and ethical manufacturing are at the heart of everything we do.

Expanding Horizons in Aerospace Machining Florida

The landscape of Aerospace Machining Florida is ever-evolving, with the growth in technological advancements and industry demands pushing the boundaries of what’s possible. At the forefront of this progression is Anco Precision Inc., a renowned family-owned CNC machine shop that has become synonymous with innovation and quality. This Deerfield Beach-based company has carved a niche in delivering high-precision machining solutions, tailored to meet the stringent requirements of aerospace clients.

Remarkably, Anco Precision Inc. provides a wide array of services, from CNC milling and turning to rapid prototyping and screw machining. These capabilities empower them to tackle intricate projects ranging from aircraft components to sophisticated optical devices. Their commitment to precision and quality is underscored by state-of-the-art equipment and a team of extensively trained machinists. The result? An unwavering standard of excellence that fuels the aerospace industry’s growth in Florida.

The emphasis on customer satisfaction and quality assurance makes Anco Precision Inc. an indispensable partner in the Aerospace Machining Florida scene. Customers consistently commending Anco’s exceptional service and fast turnaround times signifies their impact. Their ability to deliver unparalleled precision in product manufacturing while maintaining competitive pricing sets them apart in a crowded marketplace.

The Power of Experience in Aerospace Machining Florida

With over four decades of industry experience, Anco Precision Inc. represents the epitome of seasoned expertise in Aerospace Machining Florida. This wealth of experience is not just a feather in their cap; it’s the backbone of their operational efficiency and problem-solving prowess. By leveraging their extensive knowledge, Anco Precision successfully navigates complex machining challenges, providing innovative solutions to the aerospace sector.

One of the standout features of Anco Precision Inc. is their rapid prototyping capability. This service accelerates the design and testing phases, enabling aerospace clients to bring products to market faster. The ability to quickly produce prototype parts without compromising on precision is a testament to Anco’s dedication to quality and innovation.

Furthermore, Anco Precision’s dedication to adaptability and customization propels them to the forefront of Aerospace Machining Florida. They meticulously tailor their services to meet the diverse needs of clients ranging from small businesses to large corporations. This customer-centric approach ensures that every product meets exact specifications and exceeds expectations.

Innovative Solutions and Collaborative Partnerships

Anco Precision Inc. thrives on fostering collaborative partnerships with a diverse clientele, including government agencies, universities, and individual inventors. This eclectic mix of customers continually enriches their understanding of Aerospace Machining Florida, driving them to refine their processes and adopt cutting-edge technologies. By embracing collaboration, Anco Precision not only enhances their product offerings but also bolsters the innovative capacity of the industries they serve.

Their online quoting system epitomizes their commitment to streamlining processes and enhancing customer experience. By allowing clients to submit design files online for instant quotes, Anco Precision Inc. simplifies the initiation of projects, bridging the gap between concept and creation effortlessly. This innovative solution exemplifies their focus on integrating convenience with high-quality service delivery.

In the competitive sphere of Aerospace Machining Florida, Anco Precision Inc. stands as an exemplar of dedication, expertise, and forward-thinking. Their continual pursuit of excellence, coupled with a relentless drive for innovation, cements their role as a trusted leader in the industry. For those seeking precision machining solutions that push the envelope, Anco Precision remains the go-to provider, consistently delivering beyond expectations.

What sets aerospace machine shops apart in terms of precision and quality?

In aerospace machine shops like ours at Anco Precision Inc., precision is not just a goal; it’s a necessity. The aerospace industry demands components that meet exceptionally tight tolerances, often within thousandths of an inch. This level of precision is achieved through advanced CNC machining technology and skilled machinists who understand the critical nature of each part we produce. We’ve invested heavily in state-of-the-art equipment and comprehensive training to ensure that every component we manufacture can withstand the rigorous demands of aerospace applications. This dedication to precision and quality enables us to contribute effectively to the success of aerospace missions.

How important is technological innovation in aerospace machining?

Technological innovation is the heartbeat of aerospace machining. At Anco Precision, we strive to stay ahead of the curve by constantly upgrading our technology to integrate the latest advancements in CNC machining. Innovations like rapid prototyping help accelerate the design process, allowing our clients to test and refine their concepts swiftly. This results in reduced time-to-market, a crucial factor in the competitive aerospace sector. By embracing innovation, we not only enhance our capabilities but also improve the overall efficiency and quality of the components we produce. What do you think could be the next breakthrough in machining technology?

How does the choice of materials affect aerospace machining?

Material selection is pivotal in aerospace machining due to the unique requirements of the aerospace industry. For instance, materials like aluminum and titanium are commonly used because of their strength-to-weight ratio and temperature resistance. At Anco Precision, we evaluate every project to select the optimal material that balances performance, durability, and cost-effectiveness. This meticulous selection process ensures that our components not only meet the technical specifications but also contribute to the overall safety and efficiency of the aerospace systems they are part of. Understanding the properties of different materials can open up numerous possibilities in design and application.

Why is collaboration crucial in aerospace machining?

Collaboration is a cornerstone of successful aerospace machining projects. At Anco Precision, we understand that effective collaboration with clients leads to better outcomes. By involving clients throughout the design and production process, we ensure that their specific needs and visions are realized. This collaboration allows us to offer our insights and expertise while tailoring our processes to meet unique requirements. Projects that embrace a partnership mindset often experience smoother transitions from design to production, minimizing potential errors and enhancing overall satisfaction. A strong collaborative approach can be the difference between an average product and an exceptional one.

How do aerospace machine shops like Anco Precision Inc. address sustainability?

Sustainability is becoming increasingly crucial in aerospace machining. At Anco Precision, we are committed to reducing waste and optimizing resource use without compromising on quality. By adopting sustainable practices like efficient material usage and waste reduction strategies, we contribute to a smaller environmental footprint. Additionally, we explore hybrid manufacturing methods that combine traditional and digital machining approaches to enhance efficiency. This commitment to sustainability is not only about protecting the environment but also about ensuring the long-term viability of our machining processes. What sustainable practices do you think could make the biggest impact in manufacturing?

How does experience influence quality in aerospace machining?

Experience is invaluable in aerospace machining. With over 40 years in the industry, Anco Precision has developed a deep understanding of the intricate challenges that come with aerospace projects. This extensive experience allows us to anticipate potential challenges and devise innovative solutions quickly. It also ensures that we maintain high standards of quality and precision that our clients have come to expect. Leveraging our experience, we can deliver rapid prototyping services that expedite product development while maintaining accuracy. Experience brings with it a level of confidence and reliability that younger companies may still be developing.

What does the future hold for aerospace machining in Florida?

The future of aerospace machining in Florida is ripe with potential, driven by both technological advancements and growing industry demands. Being at the forefront, Anco Precision is poised to continue leading with innovation and quality. Florida’s strategic location and robust aerospace industry presence provide ample opportunities for growth and collaboration. As more companies recognize the precision and reliability that local shops offer, the demand for high-quality machining solutions will only increase. This growth presents opportunities for us to expand our capabilities, adopt new technologies, and forge partnerships that push the boundaries of what’s possible in aerospace manufacturing. What emerging trends do you think will shape the future of aerospace machining?

What are the advantages of using CNC machining in aerospace manufacturing?

CNC machining is integral to aerospace manufacturing due to its precision, efficiency, and versatility. At Anco Precision, we use CNC technology to produce complex parts with exacting detail. One major advantage is the ability to achieve high accuracy and consistency, which is crucial for parts that need to withstand extreme conditions. CNC machines also allow for greater automation, reducing the likelihood of human error and improving production speeds. This technology enables us to produce both prototypes and large production runs efficiently, ensuring that our clients receive the highest quality components on time. CNC machining stands as a testament to the power of precision engineering.

Resources

- NASA – National Aeronautics and Space Administration – The official homepage of NASA, providing information on space exploration, aeronautics, and more.

- FAA – Federal Aviation Administration – The leading authority on aviation safety and regulation in the United States.

- NIST – National Institute of Standards and Technology – A government agency promoting innovation and industrial competitiveness through advancements in measurement science.

- SAE International – A global association of engineers and technical experts in the aerospace industry, setting standards for engineering excellence.

- Lockheed Martin – A global aerospace, defense, and security company known for its advanced technology solutions.