Aluminum: Versatility in CNC Machining

In the world of CNC machining, aluminum stands out for its exceptional versatility and machinability. The metal is highly sought after in industries ranging from automotive to aerospace, thanks to its remarkable strength-to-weight ratio. This inherent property makes aluminum an ideal choice for manufacturing complex parts that need to remain lightweight yet robust.

Aluminum’s popularity also stems from its non-toxic, recyclable, and corrosion-resistant nature. The high corrosion resistance means that heavy coatings typically needed for other materials are unnecessary, which often results in cost savings and streamlined manufacturing processes. At Anco Precision Inc., we recognize these benefits, which is why aluminum is a material we frequently work with to meet our clients’ diverse needs.

CNC Machining Techniques for Aluminum

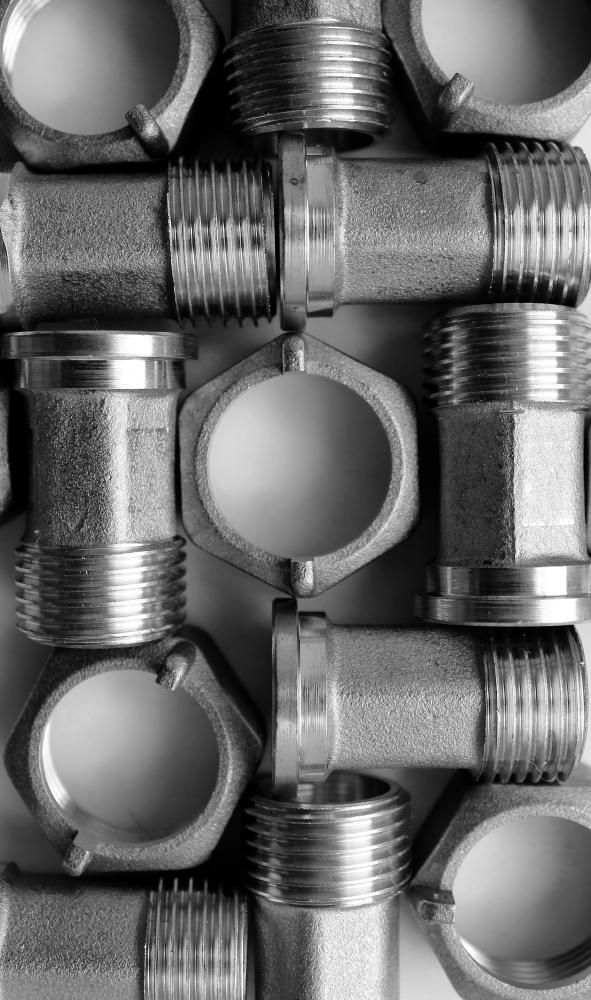

CNC machining of aluminum involves various advanced techniques, each offering unique advantages for specific applications. CNC milling is one of the most common processes, utilizing rotating cutting tools to precisely carve materials. At Anco Precision, our expert machinists are trained to operate state-of-the-art CNC milling machines, ensuring precise adherence to design specifications.

Another popular method is CNC turning, which allows for detailed material removal with high precision. This technique is particularly beneficial when manufacturing products that require cylindrical features or fine thread patterns. The ability to rapidly produce intricate components makes CNC turning invaluable, especially in projects like custom car parts and medical instruments.

For more specialized needs, CNC laser and plasma cutting processes are employed. These methods are perfect for creating intricate patterns or shapes in aluminum sheets. The fine control lasers offer ensures high accuracy in cutting, making them ideal for producing components with stringent tolerances. The team at Anco Precision leverages these varied techniques to offer a comprehensive range of services, catering to even the most demanding projects.

Choosing Aluminum Over Steel: Why It Matters

When it comes to CNC machining, many manufacturers face the decision of whether to use aluminum or steel. Both have their merits, but aluminum often comes out on top, especially for applications requiring lightweight components. Aluminum is about two to three times lighter than steel, which is a significant advantage in sectors like aerospace and automotive where reducing weight can enhance efficiency and performance.

Despite being less dense, aluminum is machinable up to four times faster than steel, a fact that reduces production time and cost. This efficiency is crucial for industries striving for quick turnaround times, such as marine and medical sectors. It also translates to reduced tool wear, an aspect appreciated by our clients at Anco Precision, who benefit from cost-effective manufacturing solutions.

While steel boasts unmatched strength, aluminum’s combination of lightweight properties and sufficient strength for most applications positions it as a preferred choice in CNC machining. The decision ultimately lies in the specific needs of a project, but for many of our clients, the benefits of aluminum CNC machining are clear and impactful.

Applications and Benefits in Different Industries

Aluminum CNC machining opens doors to myriad applications, propelling innovation across industries. In the aerospace sector, the lightweight nature of aluminum contributes to fuel-efficient and sustainable solutions, while maintaining the high standards of safety and durability required. Anco Precision has been instrumental in providing precision aluminum parts for aerospace applications, leveraging our decades of expertise.

In the medical industry, the non-toxic and adaptable characteristics of aluminum make it a valuable material for manufacturing medical devices and instruments. It is also prevalent in the automotive sector, where it helps achieve improved fuel efficiency without compromising on strength and safety. The adaptability of aluminum extends to electronics, where its sleek finish and excellent thermal conductivity are highly valued.

Our commitment at Anco Precision to using high-quality aluminum for CNC machining ensures that our clients receive components that meet and exceed industry standards. The team’s dedication to precision and customer satisfaction continues to be the hallmark of our service, supported by glowing testimonials and a loyal clientele.

Benefits of Aluminum Machining

Aluminum Machining stands out as a pivotal process in manufacturing due to its unique properties and versatile applications. One of the major advantages is aluminum’s excellent strength-to-weight ratio, which makes it ideal for industries like aerospace and automotive that require lightweight materials without compromising durability. Having spent over 40 years in the field, Anco Precision Inc. recognizes that aluminum’s corrosion resistance also adds value, reducing the need for costly coatings and prolonging the lifespan of components.

Additionally, aluminum is highly machinable, allowing for quicker processing times compared to denser metals like steel. This results in faster project turnovers and more cost-effective production, key benefits that Anco Precision clients frequently appreciate. For any custom car part or aerospace component, the machinability of aluminum can significantly reduce lead times and costs while maintaining high precision standards.

Another advantage is aluminum’s conductivity of heat and electricity, making it indispensable in electrical and thermal applications. As a conductor, aluminum is often used in electronics, where Anco Precision has successfully collaborated with electronic device manufacturers to develop intricate parts that meet rigorous industry standards.

Applications in Diverse Industries

The adoption of Aluminum Machining across various sectors is a testament to its adaptability. In the marine industry, for instance, aluminum’s resistance to saltwater makes it perfect for components subjected to harsh marine environments. Anco Precision supplies parts that deliver both performance and longevity, supporting clients in building reliable watercraft.

For the medical industry, the non-toxic nature of aluminum and its easy sterilization process ensure that the healthcare equipment manufactured is safe and durable. Anco Precision’s expertise in machining medical devices aligns perfectly with these requirements, offering precision and compliance with health standards.

The automotive sector benefits immensely from aluminum’s role in lightweighting. By replacing heavier steel components, manufacturers can produce more fuel-efficient vehicles. Anco Precision is at the forefront of this innovation, crafting parts that enhance vehicle performance without the added weight.

Moreover, the company’s proficiency in rapid prototyping allows product designers and developers to quickly iterate and refine their projects. This flexibility is crucial in the fast-paced world of product development, enabling a swift transition from concept to functional prototype.

Advanced CNC Techniques

Anco Precision Inc. employs state-of-the-art CNC techniques in Aluminum Machining to ensure the highest quality of production. CNC milling is commonly used, employing rotating cutting tools for precise removal of material. This method is not only reliable but also ensures consistent quality across repeated productions.

Another advanced technique is CNC turning, where the combination of rotational speed and cutting precision creates detailed and intricate parts. Anco’s experience in CNC turning is unmatched, offering accuracy that many industries demand for critical components in applications ranging from auto engines to medical instruments.

Our commitment to embracing advanced technologies extends to CNC laser and water cutters. These methods allow Anco Precision to craft complex geometries and intricate designs, crucial for clients seeking innovative and customized solutions. By leveraging these techniques, Anco Precision maximizes efficiency and minimizes material waste, providing a sustainable approach to manufacturing.

Precision Meets Experience

Nestled in the heart of Deerfield Beach, Florida, Anco Precision Inc. stands as a beacon of excellence in Aluminum Machining Florida. For over four decades, this family-owned CNC machine shop has woven a tapestry of expertise and reliability across numerous industries like marine, automotive, and aerospace. The commitment to precision is not just a slogan here; it’s a lifestyle deeply embedded in each machinist’s routine.

The team at Anco Precision Inc. embodies a rare blend of old-school craftsmanship and cutting-edge technology. Their extensive training ensures that every piece of equipment is used to its fullest potential, crafting products that meet even the most rigorous standards. From crafting custom car parts to intricate medical instruments, their mastery over CNC milling, turning, and screw machining sets them apart from the competition.

Aluminum Machining Florida demands a level of detail and accuracy that Anco Precision delivers with aplomb. Their customer-centric approach involves understanding specific needs and offering tailored solutions, ensuring each project is a collaborative venture. This partnership approach allows clients to feel not only satisfied but also informed and valued.

Diverse Applications of Aluminum Machining

Aluminum Machining Florida encompasses a wide array of applications, and Anco Precision Inc. takes pride in its versatility. Whether it’s the sleek lines of an auto engine or the delicate intricacies of optical devices, their portfolio is as diverse as it is robust.

One of the standout qualities of aluminum is its adaptability. This metal’s light weight, combined with its formidable strength, makes it ideal for crafting components that require both resilience and flexibility. Anco Precision capitalizes on this by delivering parts that thrive in the rigorous demands of aerospace environments and the precision required in medical fields.

In the bustling world of CNC machining, having access to rapid prototyping is invaluable. Anco Precision understands this necessity and offers a streamlined process to bring ideas from drawings to tangible products. By prioritizing speed without sacrificing quality, they enable innovators to push boundaries and explore new frontiers.

Customer Experience and Reliability

At Anco Precision, customer satisfaction is not just an outcome; it’s an ongoing commitment. Their dedication to quality is reflected in every customer interaction, ensuring that the process is as seamless as the finished product. Aluminum Machining Florida with Anco means meeting deadlines without compromise, a feat achieved through their unwavering professionalism and attention to detail.

Testimonials from satisfied clients paint a vivid picture of a company that doesn’t just meet expectations but consistently surpasses them. The quick turnaround times coupled with competitive pricing make Anco Precision an attractive partner for businesses and individuals alike. This blend of quality and affordability ensures that Aluminum Machining Florida remains accessible to a wide range of clientele.

With an intuitive online machine shop, getting started with Anco Precision is as simple as submitting a drawing file to receive an instant quote. This efficiency empowers clients to plan effectively without lengthy delays, ensuring they can focus on innovation while Anco handles the precision machining. Experience the synergy of expertise, technology, and customer care that defines Anco Precision Inc.

What are the main advantages of using aluminum in CNC machining?

Aluminum is celebrated for its impressive strength-to-weight ratio, which is vital in industries like aerospace and automotive where weight reduction is crucial. Beyond that, aluminum’s machinability is exceptional, allowing for faster processing times compared to denser metals like steel. This efficiency not only speeds up production but also helps reduce costs, a benefit our clients at Anco Precision greatly appreciate. Additionally, aluminum’s corrosion resistance and recyclability make it a sustainable choice, requiring less protective coating and offering longer-lasting durability. With these characteristics, aluminum is a versatile material that meets diverse manufacturing needs.

How do CNC machining techniques differ when working with aluminum?

When working with aluminum, we utilize a variety of CNC machining techniques tailored to the metal’s properties. CNC milling and turning are popular choices; milling uses rotating cutting tools for precision, while turning allows for detailed cylindrical features. Aluminum’s softer nature means cutting speeds can be increased without compromising quality. For intricate designs we employ CNC laser cutting, taking advantage of the fine control lasers offer to create precise patterns. Each technique is chosen based on project specifications, ensuring optimal efficiency and accuracy in aluminum machining.

Why choose aluminum over steel in CNC machining applications?

Choosing aluminum over steel often comes down to the specific project needs. Aluminum is significantly lighter, about two to three times less dense than steel, making it ideal for applications where weight is a critical factor, such as in aerospace or automotive industries. Despite being lighter, aluminum is also machinable up to four times faster than steel, which translates to reduced production times and costs. While steel offers unmatched strength, aluminum provides sufficient strength for many applications and often proves more cost-effective due to reduced tool wear and quicker processing times.

What industries benefit most from aluminum CNC machining?

Aluminum CNC machining is particularly beneficial in industries that require lightweight yet durable materials. The aerospace industry relies heavily on aluminum for components that contribute to fuel efficiency while ensuring safety and durability. In the medical field, the non-toxic nature of aluminum makes it ideal for producing safe and sterilizable medical devices. The automotive industry also benefits from aluminum’s lightweight properties, crucial for improving vehicle fuel efficiency. At Anco Precision, we provide precision aluminum parts across these sectors, ensuring our clients receive components that meet high industry standards.

How does aluminum machining improve production efficiency?

Aluminum’s machinability greatly enhances production efficiency. Compared to other metals like steel, aluminum allows for higher cutting speeds and less tool wear, thereby reducing production time and costs. At Anco Precision, we leverage these advantages to offer rapid prototyping and faster project turnovers. Furthermore, aluminum’s corrosion resistance reduces the need for additional coatings, streamlining the manufacturing process. Our clients benefit from these efficiencies, as we can deliver high-quality components quickly and cost-effectively, enabling them to meet tight schedules and budgets.

What are the advanced CNC techniques used in aluminum machining?

At Anco Precision, we employ advanced CNC techniques to maximize the potential of aluminum machining. CNC milling is a staple method, offering precise material removal with rotating cutting tools. CNC turning provides detailed finishes and intricate parts, crucial for applications requiring cylindrical shapes or fine threads. We also utilize CNC laser and water cutters for complex geometries, allowing for precise and efficient production of intricate designs. These techniques help us reduce material waste and ensure that each component meets our rigorous quality standards.

Why is aluminum machining widely used in Florida?

Florida’s diverse industries, from aerospace to marine, benefit immensely from aluminum machining. The state’s aerospace sector demands lightweight materials to enhance aircraft efficiency, and aluminum’s properties make it ideal for such applications. In marine environments, aluminum’s resistance to saltwater corrosion ensures longevity and reliability, crucial for watercraft parts. At Anco Precision, located in Deerfield Beach, we are strategically positioned to serve Florida’s varied industries, providing high-quality aluminum components that meet the specific needs of our local clientele.

How does aluminum CNC machining contribute to environmental sustainability?

Aluminum is a sustainable choice in CNC machining due to its recyclability. This metal can be recycled indefinitely without losing its properties, reducing waste and energy consumption. At Anco Precision, we prioritize using recycled aluminum whenever possible, aligning with environmentally conscious manufacturing practices. Additionally, aluminum’s corrosion resistance and lighter weight result in longer-lasting products and reduced fuel consumption, particularly in transportation applications. These factors collectively contribute to an eco-friendlier production cycle, making aluminum a responsible choice for businesses focused on sustainability.

What common misconceptions exist about aluminum CNC machining?

One common misconception is that because aluminum is lighter and softer than steel, it’s not suitable for heavy-duty applications. However, aluminum alloys can offer impressive strength and durability, sufficient for many demanding applications. Another myth is that aluminum is only used for low-cost or low-quality parts, whereas in reality, it’s prized for its efficiency and reliability across high-end industries such as aerospace and medical devices. At Anco Precision, we aim to educate our clients on the robust capabilities of aluminum machining, ensuring they choose the best material for their project needs.

Resources

- NASA – National Aeronautics and Space Administration – The official website of NASA, providing information on space exploration, aeronautics, and scientific discoveries.

- National Institutes of Health – The NIH is the primary agency for conducting and supporting medical research, with a focus on improving health and wellbeing.

- National Institute of Standards and Technology – NIST is a non-regulatory federal agency that promotes innovation and industrial competitiveness through the advancement of measurement science.

- National Transportation Safety Board – The NTSB is an independent federal agency dedicated to promoting transportation safety and investigating accidents across various modes of transportation.

- Bureau of Labor Statistics – The BLS is a principal federal agency responsible for measuring labor market activity, working conditions, and price changes in the economy.