Diverse Applications of EDM Services

Electrical Discharge Machining (EDM) is a highly versatile technology, utilized across various industries for precision machining needs. From aerospace to automotive, its applications are wide-ranging and cater to diverse requirements. Unlike traditional machining methods, EDM uses electrical discharges or sparks to shape materials, allowing for the creation of intricate and complex geometries.

In the automotive industry, EDM is employed to manufacture precision components such as gears, engine parts, and molds, ensuring each piece meets the highest standards of accuracy and function. Similarly, the medical field benefits from EDM services through the fabrication of intricate surgical instruments and prosthetics. This process ensures that the strict tolerances and material integrity necessary for medical applications are consistently achieved.

Precision and adaptability make EDM a go-to solution for industries that demand high-caliber results. Companies seeking EDM services near me will find that this technology supports their need for innovative solutions, whether it’s crafting complex parts for aircraft or developing bespoke tools for specialized applications.

Advantages of Seeking Local EDM Services

Choosing local providers for EDM services presents several distinct advantages. Proximity facilitates better communication and collaboration between manufacturers and clients, ensuring that specifications are precisely met. This can lead to faster turnaround times, as there is a reduced need for extended shipping periods or time-zone disruptions in communication.

Local businesses also tend to have a deeper understanding of regional market demands and customer expectations. As such, companies providing EDM services near me can tailor their offerings to meet the specific needs of their customers, providing a customized approach that might be less feasible with distant providers. Regular site visits enable real-time feedback and project adjustments, enhancing the overall quality of the finished product.

By supporting local businesses, clients contribute to the regional economy, fostering growth and creating a more sustainable business ecosystem. This commitment to local partnerships can result in long-term collaboration and mutual benefits for both service providers and their clients.

Selecting the Right EDM Provider

When searching for EDM services near me, selecting the right provider is crucial to achieving desired outcomes. It’s essential to evaluate the expertise and technological capabilities of potential providers to ensure they can meet the precision requirements of your projects. Reviewing testimonials and case studies can provide insight into a company’s track record for delivering quality results.

Consideration should also be given to the provider’s approach to customer service and their ability to maintain transparent and open lines of communication. Responsive support and the willingness to engage in collaborative problem-solving are key traits of a reliable EDM service provider.

The capacity for innovation and adaptability is another important factor. A provider that embraces new technologies and methodologies is more likely to offer cutting-edge solutions that enhance production efficiency and product quality. Additionally, a commitment to sustainability practices and ethical operations can be a notable advantage, aligning with broader corporate responsibility goals.

By carefully evaluating these factors, businesses can confidently select an EDM service provider that aligns with their strategic objectives and operational needs, ensuring successful project outcomes and lasting partnerships.

Insider Tips for Effective EDM Collaboration

When engaging with a company offering EDM services near me, a few insider tips can facilitate an effective collaboration. Firstly, clear and detailed communication is paramount. Sharing comprehensive specifications and expectations from the outset helps in setting realistic goals and timelines for project completion.

Establishing a collaborative mindset can enhance the working relationship. Open dialogue encourages the exchange of ideas, fostering a creative environment where innovative solutions can flourish. This proactive approach can also aid in quickly addressing and resolving any unforeseen challenges that may arise during the machining process.

Flexibility is another critical component of successful EDM collaboration. Being open to adjustments in design or process as the project evolves can lead to enhanced results. Regular progress reviews and feedback sessions can ensure that the project stays on track and aligns with the client’s vision.

Ultimately, a successful partnership with EDM service providers emphasizes strong communication, collaboration, and adaptability, ensuring that both parties work together seamlessly to achieve outstanding results. Leveraging these insights can maximize the benefits obtained from local EDM services, providing a competitive edge in rapidly evolving markets.

Principles of EDM Machining

The Science Behind the Sparks

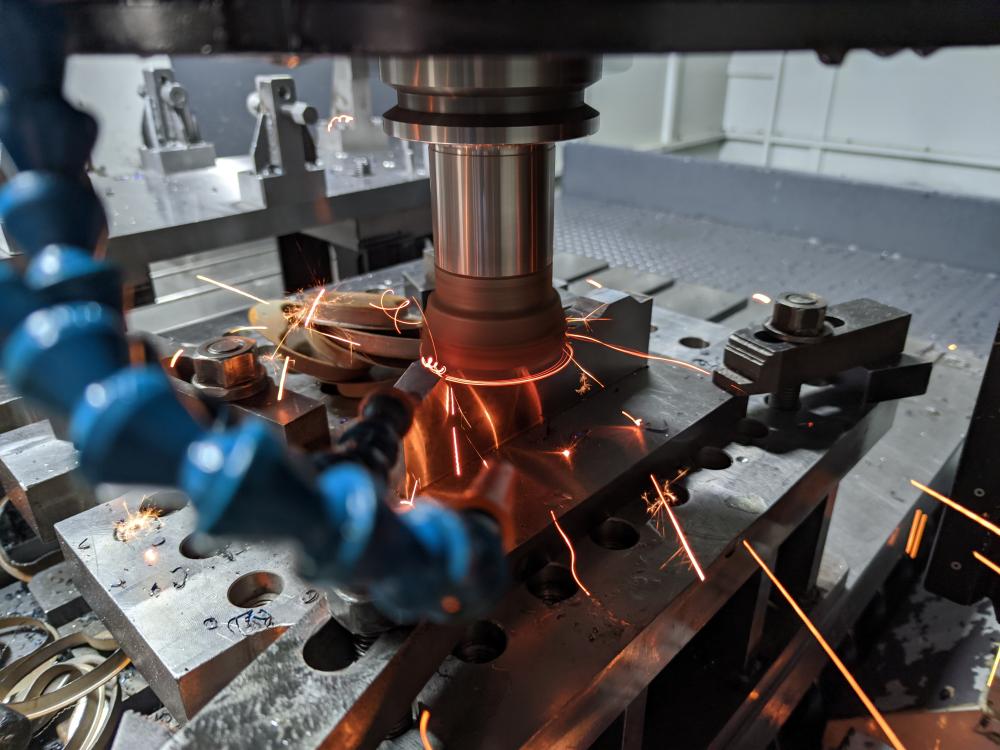

Electrical Discharge Machining, or EDM Machining, is a fascinating technology that uses thermal energy to remove material, avoiding physical contact with the workpiece. The process involves generating sparks between an electrode and the conductive material being worked on. These sparks, which can reach temperatures as high as 21,500ºF, erode the material, transforming solid metal into vapor and molten debris. The lack of physical contact allows intricate and delicate parts to be crafted with high precision, a feature that’s invaluable to many industries.

Applications Across Industries

EDM Machining finds invaluable applications in industries where traditional machining processes fall short. In aerospace, it is used to create components like turbine discs from high-grade nickel alloys, offering precision and exceptional surface finishes. The medical industry utilizes EDM for crafting burr-free implant devices, such as hip and knee replacements, ensuring they meet critical safety and performance standards. Automotive and electronics sectors similarly benefit from EDM’s capability to produce complex geometries and tight tolerances.

Advantages and Challenges of EDM Machining

Benefits of EDM

The advantages of EDM Machining are many and varied, attracting companies like Anco Precision Inc. to integrate it into their service offerings. EDM is unparalleled in its ability to cut complex shapes, deep holes, and intricate undercuts without leaving burrs or tool marks. Its non-contact nature means it imparts minimal force, allowing even the most delicate of parts to be machined without risk of damage. Additionally, materials of varying hardness are no challenge for EDM, offering versatility unmatched by conventional machining methods.

Considerable Challenges

Despite its numerous advantages, EDM Machining presents certain challenges that manufacturers must navigate. The process is energy-intensive, which can impact both operational costs and environmental sustainability, an ever-increasing concern for industries worldwide. Moreover, the complexity of EDM demands a qualified workforce, as the skill set required is specialized, making it difficult to find and retain expert machinists. The size of the workpieces is also a limiting factor, with EDM more suited to small-scale and intricate parts.

Personal Insight and Experience

From the perspective of Anco Precision Inc., leveraging EDM Machining has brought a blend of challenges and triumphs. Their machinists undergo rigorous training to master the art, ensuring that projects meet the precision and quality customers expect. The journey, while demanding, is rewarding, offering a competitive edge in sectors like aerospace and medical where precision is non-negotiable. Anco Precision Inc. stands testament to how effectively overcoming these challenges can lead to success.

Innovative Uses and Future Trends of EDM Machining

Exploring New Frontiers

Industries are continuously discovering new applications for EDM Machining, pushing the boundaries of what’s possible. Emerging technologies, such as additive manufacturing, are being integrated with EDM to create hybrid processes that offer even greater flexibility and capability. By combining these technologies, companies are able to produce parts that are not only complex but also highly customizable, meeting the ever-evolving needs of their customers.

The Path Forward

The future of EDM Machining is bright, with ongoing research aimed at improving efficiency and reducing environmental impact. Innovations in electrode materials and dielectric fluids promise to enhance the speed and sustainability of the process. The development of automated EDM systems is also on the rise, potentially reducing the reliance on skilled technicians while increasing throughput. For companies like Anco Precision Inc., staying at the forefront of these trends is crucial to maintaining their reputation as industry leaders.

Principles of EDM Wire Cutting

EDM Wire Cutting, known as Electrical Discharge Machining, employs a thin wire for precision metal cutting. This process is ideal for hard metals that traditional machining methods struggle with. In EDM, an electrically charged wire discharges sparks to erode conductive materials, allowing intricate shapes and tight tolerances to be achieved.

One of the distinct advantages of EDM Wire Cutting is its capacity for producing complex geometries. Unlike conventional methods, it can cut intricate patterns and small features in hard metals without inducing stress on the material. This is particularly relevant in industries such as aerospace and medical, where precision is not just a desire but a necessity.

EDM Wire Cutting requires minimal force during the cutting process, which enhances its utility when working with delicate or thin parts. By eliminating the physical pressure associated with traditional machining, the risk of damaging the part is significantly reduced. This aspect makes it an appealing choice for working with expensive or irreplaceable materials.

Advanced Applications in Various Industries

Industries across the spectrum, from automotive to electronics, benefit from the precision of EDM Wire Cutting. In the medical field, for example, it allows for the fabrication of complex components like implants and surgical instruments with great precision. This ensures a perfect fit and function, critical for patient safety and device efficacy.

The aerospace industry relies heavily on EDM Wire Cutting for manufacturing turbine blades and other components that require exacting standards. Components must withstand extreme conditions, and the precision and consistency provided by EDM are invaluable. It enables complex designs that improve performance and efficiency in modern aircraft.

Automotive manufacturers use EDM Wire Cutting for prototyping new parts and components. This technology allows engineers to experiment with designs before committing to large-scale production. It supports innovation by enabling rapid iterations and testing of parts, leading to more refined and efficient automotive solutions.

In electronics, EDM Wire Cutting is essential for creating precise components such as connectors and semiconductor parts. As devices become smaller, the ability to manufacture tiny components with exact dimensions and high-quality finishes becomes increasingly critical, making EDM an indispensable tool in this sector.

Expert Insights and Technological Advancements

Experts in the machining field recognize that the capabilities of EDM Wire Cutting continue to expand with technological advancements. Modern machines are highly automated, allowing for precise control over the cutting process and the ability to perform complex tasks with minimal human intervention. This not only boosts efficiency but also reduces the potential for human error.

Anco Precision Inc. highlights the importance of continuous training and adaptation to new technologies. Their machinists, equipped with state-of-the-art tools, can leverage EDM Wire Cutting to meet diverse customer needs efficiently. They emphasize that such technology not only improves quality but also allows for competitive pricing.

Looking forward, the integration of EDM Wire Cutting with other advanced manufacturing technologies, such as CNC and additive manufacturing, opens new possibilities. Hybrid systems offer flexibility and capability, combining the strengths of multiple processes to produce superior parts. This trend is reshaping the manufacturing landscape by reducing lead times and improving product quality.

Personal testimonies from industry professionals affirm the transformative impact of EDM Wire Cutting. Machinists often describe it as an eye-opening experience, noting the precision and versatility it brings to their work. As technology progresses, the potential for EDM to solve increasingly complex manufacturing challenges continues to grow.

What are the advantages of using local EDM services?

Choosing local EDM services can significantly streamline your project by facilitating better communication and collaboration. At Anco Precision Inc., we find that being in close proximity to our clients means faster turnaround times and a more personalized approach. Our local expertise allows us to understand and adapt to regional market demands, delivering a tailored service that meets specific customer needs. By reducing the need for long-distance shipping, we minimize time-zone disruptions and ensure real-time feedback, which enhances the overall quality of the finished product. Additionally, supporting local businesses like ours contributes to the regional economy, fostering long-term growth and collaboration.

Are there misconceptions about the complexity and cost of EDM services?

One common misconception about EDM services is that they are prohibitively expensive and overly complex. In reality, while EDM processes can be intricate, they offer unique advantages that often justify the investment. For instance, EDM machining allows for the creation of complex shapes and intricate geometries that traditional methods cannot achieve. At Anco Precision Inc., we emphasize precision and efficiency, which often leads to cost savings in the long run through reduced material waste and fewer production errors. Additionally, we focus on clear communication and detailed planning, which demystifies the process for our clients and ensures transparency in pricing.

How do I select the right EDM provider for my project needs?

Selecting the right EDM provider is crucial to the success of your project. It’s essential to evaluate the provider’s expertise, technological capabilities, and track record. At Anco Precision Inc., we offer over 40 years of experience and state-of-the-art equipment to handle a wide range of machining requirements. Testimonials and case studies from previous clients can offer valuable insights into a company’s ability to deliver quality results. Moreover, consider the provider’s approach to customer service and communication. A reliable provider is responsive, engages in collaborative problem-solving, and embraces innovation. Ultimately, the right provider should align with your strategic objectives and operational needs, ensuring a strong partnership and successful outcomes.

What are the core principles of EDM machining?

EDM machining, or Electrical Discharge Machining, operates on the principle of using electrical discharges to erode material. This process involves generating sparks between an electrode and a conductive workpiece, allowing for high-precision machining without direct contact. At Anco Precision Inc., we leverage this technology to handle intricate and delicate parts in industries such as aerospace and medical. The key advantage is its ability to achieve complex shapes without leaving burrs or tool marks. However, it’s important to note that EDM is more suited for small-scale and intricate components due to its energy-intensive nature.

How does EDM wire cutting differ from traditional machining methods?

EDM wire cutting is distinct from traditional machining in that it uses a thin wire to cut through conductive materials, allowing for precise and intricate shapes. Unlike conventional methods, which can exert physical pressure and induce stress, EDM wire cutting uses electrical discharges to erode the material. This lack of physical contact is ideal for delicate or thin parts, reducing the risk of damage. At Anco Precision Inc., we find this method particularly useful for producing complex components in industries like aerospace and medical, where precision and exact tolerances are critical.

What are some advanced applications of EDM machining in different industries?

EDM machining has a wide array of advanced applications across various industries due to its precision and ability to handle complex geometries. In aerospace, it is used for manufacturing turbine blades and other components that require exacting standards. In the medical field, EDM allows for the production of intricate implants and surgical instruments that must meet stringent safety and performance criteria. At Anco Precision Inc., we’ve seen EDM’s impact in automotive prototyping, enabling rapid iterations and testing of parts before full-scale production. The electronics industry also benefits from EDM’s capability to produce precise connectors and semiconductor parts, supporting the miniaturization of devices. These applications underscore the versatility and indispensability of EDM in modern manufacturing.

Resources

- NASA – National Aeronautics and Space Administration – Official website of NASA, providing information on space exploration, aeronautics, and scientific discoveries.

- National Institutes of Health (NIH) – The primary agency for conducting and supporting medical research in the United States.

- American Society of Mechanical Engineers (ASME) – A professional organization focused on advancing engineering and technology across various industries.

- National Institute of Standards and Technology (NIST) – Promotes innovation and industrial competitiveness through advancements in measurement science and standards.

- Engineering Toolbox – A resource for engineering professionals, providing tools and information on a wide range of engineering topics.