Embracing Low Volume Production

At Anco Precision Inc., the beauty of Low Volume Production Machining lies not just in the art of precision, but in the ability to tailor unique solutions for diverse industries. From the exhilarating world of automotive innovations to the meticulous demands of medical devices, our journey into low volume production has been nothing short of transformative. This process allows businesses to bring creative and groundbreaking products to life without the hefty price tags associated with mass production.

Low volume production machining, a dance of art and science, enables customized parts with intricate designs to be manufactured on a tighter budget and schedule. This results not only in cost savings but also in a new realm of possibilities for product innovation. By embracing this model, we empower companies to prototype quickly, adjust designs as needed, and even produce limited editions for specific market segments. The landscape is evolving, and we are excited to be part of it.

Technological Advantages in Low Volume Machining

Over our 40 years of experience at Anco Precision, we’ve witnessed how technology has revolutionized Low Volume Production Machining. Advanced CNC equipment and rapid prototyping have become the backbone of our operations, allowing for enhanced precision and flexibility. CNC machining, in particular, has opened new doors by providing rapid and accurate production capabilities, crucial for industries like aerospace where exact specifications are non-negotiable.

The integration of cutting-edge technology such as 3D printing and CNC tools in our processes has minimized setup costs and reduced lead times. This synergy between traditional craftsmanship and modern innovation ensures we deliver each product to exacting standards. Our team’s expertise ensures that even the most complex designs come to life seamlessly, aligning with customer expectations every step of the way.

Whether it’s CNC milling or CNC turning, the blend of accuracy and speed is undeniable. The ability to adapt and respond to intricate part requirements with finesse is what sets us apart in the industry. As the demand for unique, engineered solutions continues to grow, our methods evolve to meet these needs head-on.

Partnerships and Customer Experiences

Our collaborations span a spectrum of sectors, making Low Volume Production Machining a dynamic and rewarding endeavor. Each project is a testament to our commitment to quality and innovation. We have built enduring relationships with government agencies, automotive giants, and inventive start-ups by consistently delivering high-caliber results. Customers have praised our ability to meet tight deadlines without compromising on quality–an achievement we attribute to our team’s dedication and the close-knit nature of our operation.

Working with Anco Precision means engaging in a partnership rooted in transparency and collaboration. Our machinists are not only skilled but possess a deep understanding of the nuances involved in each project. This wealth of experience ensures that every client receives personalized solutions tailored to deliver the best possible outcome.

We take pride in supporting our clients’ visions from concept to creation. By offering instant quotes and detailed consultations, we streamline the process, making it as accessible and efficient as possible. This approach is not just a service; it is a commitment to helping businesses thrive.

Unique Challenges and Innovations

The journey through Low Volume Production Machining is not without its challenges, but therein lies the opportunity for innovation. At Anco Precision, we view each obstacle as a chance to refine our process and enhance our expertise. Customized manufacturing presents its own set of hurdles–from design complexities to material constraints–but it also drives us to push the boundaries of what’s possible.

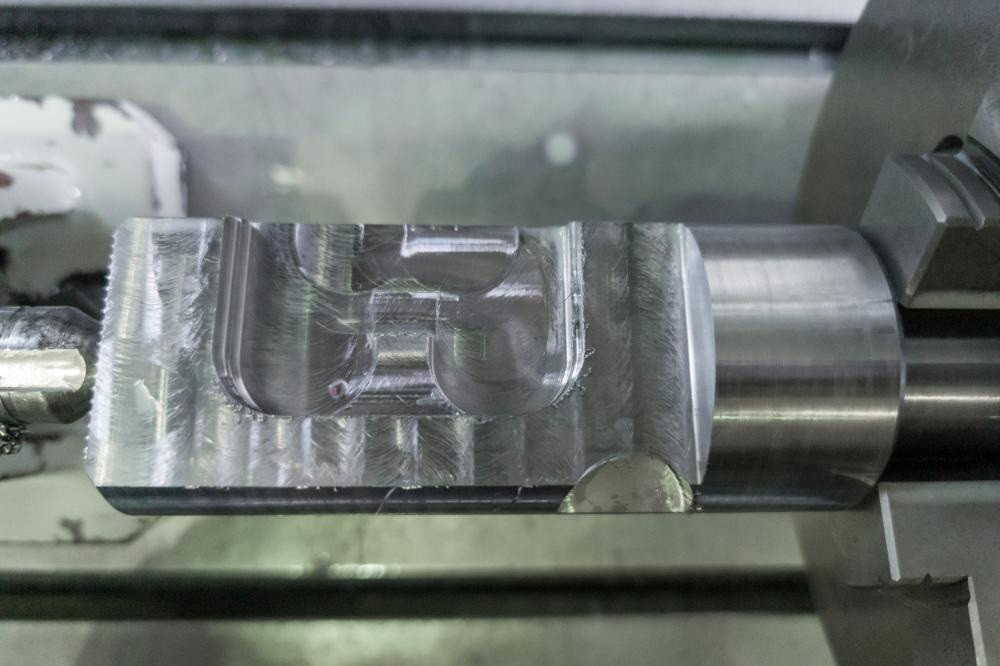

One memorable project involved creating bespoke parts for a high-performance auto engine. The adventure of working through intricate geometries with strict tolerances was a masterclass in precision engineering, demonstrating our capability to tackle even the most demanding requirements.

Our commitment to innovation extends to embracing new technologies and methodologies that enhance our capabilities. This proactive approach ensures we are always ready to meet the evolving needs of our clients, cementing our reputation as leaders in the field of low volume production machining.

Precision Matters: Delivering Excellence in Production Machining

Having worked alongside the dedicated team at Anco Precision Inc., I’ve seen firsthand how precision isn’t just a buzzword–it’s a commitment. The realm of Production Machining demands an unwavering attention to detail, where each component must meet exact specifications. Anco Precision’s machinists, with over 40 years of industry experience, embody this ethos through their meticulous approach to every project, ensuring exceptional customer satisfaction.

The precision that comes with expertise is evident in how Anco tackles complex projects. Whether producing custom parts for the aerospace industry or intricately machined components for medical devices, the focus remains on achieving 100% precision. This level of detail not only enhances the quality of each product but also fosters trust and reliability with clients, a testament to Anco’s reputation in the Production Machining field.

Within the fast-paced environment of a CNC machine shop, delivering excellence requires more than just skill–it requires the right tools. Anco Precision invests significantly in state-of-the-art equipment, allowing their team to excel in CNC milling, CNC turning, and rapid prototyping. By combining advanced technology with the expertise of highly skilled machinists, Anco continues to set the standard in Production Machining.

Diverse Perspectives: Meeting Varied Industry Needs

Production Machining is not a one-size-fits-all service; it’s an art form that adapts to the needs of various sectors. Anco Precision serves a wide array of industries, including marine, automotive, and medical fields, each with its unique challenges and specifications. The ability to pivot and adapt machining processes to meet these diverse requirements is a hallmark of Anco’s versatility and expertise.

One of the most transformative experiences I’ve encountered at Anco is witnessing the team’s capability to deliver precision machining services tailored to customer-specific demands. For instance, crafting components for marine applications requires different considerations than those for the medical industry. Yet, Anco’s team approaches each project with the same level of intensity and precision, ensuring that all customer specifications are met, regardless of complexity.

In my professional journey with Anco, I’ve observed how the company maintains its competitive edge by blending traditional skills with innovative technologies. By staying abreast of the latest advancements in Production Machining, Anco remains a frontrunner in the industry, always ready to tackle new challenges with agility and precision.

Customer-Centricity: Building Long-Lasting Partnerships

Listening to Customer Needs

At Anco Precision, customer relationships are built on trust and open communication. The team places a premium on understanding client needs, which is crucial to delivering high-quality Production Machining services. Through consultations and collaboration, we ensure that customer expectations are not just met, but exceeded.

Delivering Quick and Efficient Service

One of the standout features of Anco’s service is the speed and efficiency with which projects are completed. Thanks to streamlined processes and an online quote system, customers can receive instant feedback on their projects, expediting the production timeline. This quick turnaround is particularly beneficial for industries that operate under tight schedules, making Anco a preferred partner for time-sensitive projects.

Commitment to Excellence

Anco’s pursuit of perfection in Production Machining translates into long-term partnerships with clients. By consistently delivering quality results and maintaining competitive pricing, Anco not only meets customer expectations but also builds a foundation for future collaboration. Clients from various sectors continue to choose Anco Precision for their machining needs, confident in the knowledge that they will receive the highest caliber of service.

- Exceeding customer expectations through precision and quality.

- Facilitating fast project timelines with an efficient quote system.

- Fostering long-term partnerships through reliable service.

Precision in Production Machine Shop

Having worked with Anco Precision Inc., I’ve experienced firsthand the intricate dance of precision and efficiency in a Production Machine Shop. The essence of success here is a potent blend of skilled craftsmanship, cutting-edge technology, and rigorous quality assurance. Each component crafted in a production machine shop is a testament to the machinist’s expertise and the state-of-the-art equipment they employ. The team at Anco Precision, with decades of experience, thrives on challenges, from crafting minute medical instruments to robust automotive parts.

The journey of a part through the shop is a symphony of processes–CNC milling, turning, and prototyping intertwine to cater to diverse industrial needs. These tasks go beyond mere repetition; they are exercises in creativity and problem-solving, ensuring that precision is not just a goal but a certainty. The shop echoes with the hum of machinery, each sound a promise of meticulous craftsmanship. It’s a community united by a shared commitment to delivering not only parts but confidence in each project.

Navigating the Complexity of Production Machine Shop

The complexity faced in a Production Machine Shop can be daunting yet invigorating. At Anco Precision, the diversity of industries catered to–from aerospace to marine–demands a keen adaptability. Each project brings its own set of challenges, yet this only fuels the ingenuity of the team. There’s a palpable sense of excitement when a new blueprint arrives, sparking conversations and brainstorming sessions, each machinist eager to leave their mark on a unique challenge.

There’s a meticulous rhythm in the shop, where every detail matters. The layout is crucial; machines are positioned for optimal workflow, ensuring seamless transitions from one process to the next. Here, efficiency is not just a concept but a practice honed over years of experience. Safety protocols are ever-present, guiding every movement, every decision, ensuring that while creativity is encouraged, precision is never compromised.

In this environment, learning never halts. Each day presents an opportunity to hone skills, to embrace new technologies, to push the boundaries of what’s possible. There’s an unspoken camaraderie among the team, a collective pursuit of excellence, underscored by a genuine passion for the craft. The production machine shop is a space of perpetual evolution, where each project is an opportunity to innovate, to perfect, to exceed expectations.

Embracing Innovation in Production Machine Shop

Innovation in a Production Machine Shop like Anco Precision is not merely about keeping up with technological advancements; it is about embracing them to redefine what’s achievable. The integration of CNC technologies has revolutionized our processes, allowing for unprecedented precision and efficiency. As someone who has witnessed this transformation, the ability to swiftly adapt and harness new tools and techniques is a remarkable aspect of the work environment.

At Anco Precision, the conversation around innovation is dynamic and ongoing. It’s about leveraging experience to bring new ideas to life and using technology as a bridge to creativity. In this shop, there’s a commitment to continual improvement–not just in the parts created but in the processes themselves. Machine upgrades, software improvements, and training sessions are all essential components of this evolving landscape.

To navigate a production machine shop successfully, one must appreciate the balance between tradition and innovation. It’s a place where knowledge is both shared and revered, where mentorship is as critical as the machinery itself. My time in this environment has shown me that the true heartbeat of a successful production machine shop lies in its adaptability, its people, and its relentless pursuit of precision and excellence.

What are the main benefits of Low Volume Production Machining for businesses looking to innovate while managing costs?

Low Volume Production Machining offers businesses a unique opportunity to innovate without incurring the high costs typically associated with mass production. At Anco Precision, we’ve observed that this approach allows for greater flexibility in prototyping, enabling rapid iterations and design tweaks. This is particularly beneficial for industries like automotive or medical devices, where development timelines can be tight. Additionally, by not committing to large volumes upfront, businesses can test market responses and adjust accordingly, minimizing financial risk.

From a personal standpoint, I’ve found that discussing goals and prototypes early with clients helps refine their vision and make the most of Low Volume Production Machining. Have you considered how small-scale production might fit into your business strategy, or are you still weighing the costs versus benefits?

How does the integration of CNC technology enhance the capabilities of Low Volume Production Machining?

Our extensive experience with CNC technology at Anco Precision illustrates just how transformative it can be. CNC machining enhances precision and efficiency, providing extraordinary detail and accuracy that are indispensable for complex industries like aerospace or healthcare. The ability to produce intricate designs quickly and accurately is a game-changer, reducing lead times and setup costs.

Additionally, technologies like 3D printing complement CNC machining, offering even more flexibility. This mix of traditional and modern techniques encourages innovative solutions that might not have been feasible before. How might CNC’s precision impact your projects currently, and have you explored combining it with other technologies like 3D printing?

What unique challenges does Low Volume Production Machining present, and how can they be addressed effectively?

Challenges in Low Volume Production Machining often revolve around material constraints and complex design requirements. At Anco Precision, our approach is to view these challenges as opportunities for innovation. This mindset has led us to develop bespoke parts for demanding applications, like high-performance auto engines, which require deft engineering and precise execution.

Addressing these challenges involves fostering close collaboration with clients to ensure every detail aligns perfectly with their needs. Have you encountered design complexities that seemed insurmountable, and if so, what steps did you take to overcome them?

In what ways do partnerships and customer relationships play a role in the success of Low Volume Production Machining?

Partnerships are at the heart of our success at Anco Precision. Our commitment to transparency and collaboration has helped us forge strong relationships across various sectors, from government agencies to start-ups. By building trust through open communication and delivering consistent quality, we’ve maintained a loyal customer base that appreciates our dedication to excellence.

Moreover, understanding customer needs deeply enables us to tailor solutions that exceed expectations. Engaging clients early and offering instant quotes simplifies the process, encouraging partnerships that last. How important do you find customer relationships in your industry’s success, and what strategies have you employed to nurture them?

How do technological advancements in Production Machining contribute to achieving precision and reliability?

Technological advancements in Production Machining, such as those adopted at Anco Precision, play a pivotal role in achieving unparalleled precision and reliability. Enhancements in CNC milling, turning, and rapid prototyping ensure that each part meets exact specifications, crucial for sectors like aerospace where precision is non-negotiable.

Consistently updating our equipment and adopting new methodologies ensure we remain at the forefront of the industry, delivering products that meet rigorous standards. This ongoing investment in technology reflects our commitment to high-quality outcomes. Have you considered how embracing new technologies could resolve any current limitations you face in production quality?

What strategies can help navigate the complexity of operating a successful Production Machine Shop?

Navigating the complexity of a Production Machine Shop involves meticulous planning and a commitment to continuous improvement. At Anco Precision, we emphasize an efficient layout, stringent safety protocols, and a workflow optimized for seamless transitions between processes. This attention to detail ensures productivity and fosters a culture of innovation.

Moreover, fostering an environment that encourages skill development and adaptability helps our team meet diverse industry demands. Each project becomes an opportunity to learn and innovate, pushing the boundaries of what’s possible. How have you structured your operations to handle complexity, and do you have processes that could benefit from a fresh perspective?

How does Anco Precision integrate innovation into its Production Machine Shop to maintain a competitive edge?

Innovation at Anco Precision is woven into the fabric of our operations. By actively integrating cutting-edge CNC technologies, we ensure high precision and efficiency in our processes. Embracing innovation also means continually improving our methodologies and adopting the latest advancements.

Our commitment to innovation is bolstered by a culture of ongoing dialogue and mentorship, allowing us to stay agile and responsive to market needs. This adaptability is crucial for maintaining a competitive edge. Have you considered how innovation could open new avenues for your business, and are there current hurdles you wish to overcome?

Resources

- National Institute of Standards and Technology (NIST) – Official website of NIST, providing standards and technology-related resources.

- Manufacturing.gov – Official website for U.S. Manufacturing Resources, offering information on manufacturing initiatives and resources.

- Engineering Toolbox – A comprehensive resource for engineering professionals, providing tools and information for various engineering disciplines.

- – Website of the Institute for Manufacturing at Carnegie Mellon University, offering research and educational resources in manufacturing.

- – Official website of the College of Architecture, Design, and Construction at Auburn University, offering resources for design and construction professionals.