Overview of Production Machine Shops

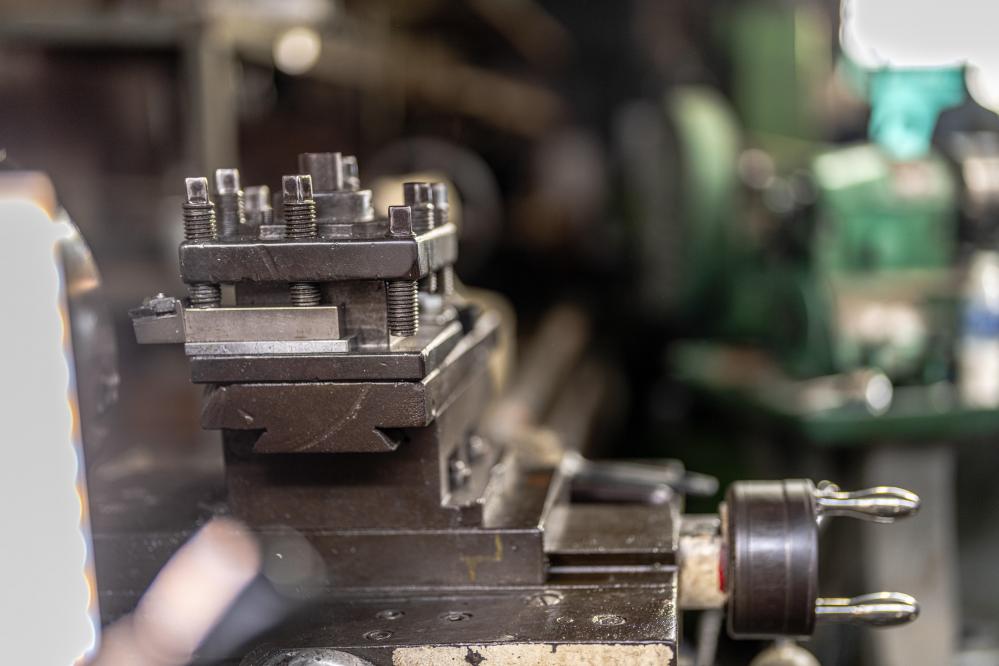

In the intricate world of manufacturing, a Production Machine Shop like Anco Precision Inc. becomes indispensable for industries seeking high precision and exceptional quality. These shops specialize in using advanced machining techniques, such as CNC milling and turning, to create components essential for sectors ranging from marine to aerospace. The capability to transform raw materials into precisely crafted products forms the backbone of modern engineering and manufacturing.

One of the unique aspects of a Production Machine Shop lies in its dedication to precision. With over 40 years of experience, Anco Precision Inc. exemplifies this commitment through its skilled machinists and state-of-the-art equipment. Their services extend to the production of custom parts for highly technical fields, ensuring that each component meets rigorous industry standards. This dedication to quality makes them a trusted partner for businesses requiring reliable machining services.

Machining Capabilities and Innovations

The capabilities of a Production Machine Shop are diverse and continuously evolving. Anco Precision Inc. offers an impressive array of services, including CNC milling, CNC turning, rapid prototyping, and screw machining. Such versatility ensures that the company can handle a wide variety of project demands, from custom automotive parts to intricate medical instruments.

Innovations in machining technology play a pivotal role in enhancing efficiency and accuracy. Anco Precision Inc. leverages cutting-edge equipment, enabling them to deliver rapid turnarounds without compromising on quality. Customers appreciate their ability to provide instant quotes via their online platform, simplifying the initial stages of project planning and allowing for seamless collaboration.

Customer Experiences and Success Stories

For many clients, working with a Production Machine Shop like Anco Precision Inc. means more than just receiving precise parts; it involves engaging with a team committed to customer satisfaction. Testimonials frequently highlight the company’s competitive pricing, prompt delivery times, and the meticulous quality of their output.

One such success story involves an automotive client who required custom engine components with tight tolerances. Anco Precision Inc.’s experienced machinists delivered parts that not only met specified dimensions but also performed flawlessly under real-world conditions. These anecdotes affirm the shop’s reputation as a reliable partner in production machining.

Furthermore, Anco’s adaptability across various industries–from government agencies to educational institutions–speaks volumes of their capacity to meet diverse needs. This flexibility has garnered them a loyal customer base that spans different sectors, each benefiting from their expertise.

Commitment to Quality and Customer Service

The ethos of a successful Production Machine Shop is grounded in quality and customer service. Anco Precision Inc. epitomizes this philosophy by ensuring that each machinist undergoes rigorous training. This helps them maintain the exacting standards necessary for their work, whether dealing with the complexity of aerospace components or the precision demands of optical devices.

Their Deerfield Beach facility is more than just a workplace; it’s a hub of innovation and meticulous craftsmanship. With operations running from Monday to Friday, Anco maintains a strong emphasis on service excellence. Their proactive approach to problem-solving and open communication channels with clients ensures projects are completed to satisfaction and in a timely manner.

The company’s commitment to community and industry collaboration is evident through its partnerships with product designers, mechanics, and scientists. By fostering these relationships, Anco Precision continues to lead as a premier Production Machine Shop, serving as a beacon of quality and innovation within the machining industry.

Precision in Production Machining

At the heart of any successful production machining operation lies precision. Anco Precision Inc. exemplifies this concept, offering unparalleled accuracy in CNC machining services. This commitment ensures that every customer’s specifications are met with remarkable attention to detail, regardless of the industry’s complexity–be it marine, automotive, or aerospace. Their machinists, trained on cutting-edge technology, highlight the crucial role of skill in maintaining high standards and delivering exceptional products.

In my last interaction with Anco Precision, I witnessed firsthand the dedication they put into ensuring each component met precision benchmarks. Such dedication is not merely a claim; it is a practice ingrained in the daily operations at their Deerfield Beach facility. This precision is the cornerstone of their promise to deliver competitive prices without compromising on quality.

Diversity in Services Offered

When discussing production machining, one cannot overlook the breadth of services Anco Precision provides. Specializing in CNC milling, CNC turning, rapid prototyping, and screw machining, they accommodate a wide array of manufacturing needs. This versatility allows them to tackle diverse projects, from custom car parts and electronic devices to medical instruments and optical devices.

During a tour of their facility, I was introduced to various projects that exemplified their range–each showcasing unique challenges that were expertly addressed. This ability to adapt and deliver customized solutions sets Anco Precision apart in the crowded field of production machining.

Anco Precision’s reputation for quick deliveries and consistent quality underscores their reliability. Clients frequently commend their ability to offer rapid turnaround times, a feature that is particularly advantageous in industries where time is of the essence. This efficiency does not sacrifice quality, thanks to rigorous standards upheld throughout the production process.

The approaches they employ are not one-size-fits-all; they embrace innovative techniques tailored to specific requirements, ensuring every project receives the attention it deserves. This strategic flexibility is pivotal in catering to industries with varying demands and expectations.

Customer-Centric Approach

Integral to Anco Precision’s success in production machining is their commitment to customer satisfaction. They provide instant quotes through an intuitive online machine shop, simplifying the procurement process for clients. By submitting a drawing file, customers receive personalized quotes, facilitating the swift initiation of projects.

Clients, ranging from government agencies to product designers, consistently express satisfaction with Anco’s services. Testimonials sing praises of their professionalism and the assurance of receiving products that maintain the highest levels of precision. This customer-centric model is a testament to their enduring reputation in the machining industry.

For anyone in need of machining services who values quality and reliability, Anco Precision represents a trustworthy partner. Their transparent processes and dedication to meeting customer needs set a benchmark for excellence in production machining. They remain accessible, welcoming inquiries and quote requests during their operating hours, ensuring that support and expertise are never too far away.

Precision in Low Volume Machining

Low Volume Production Machining is not just about producing fewer parts; it’s an art of balancing precision and efficiency. At Anco Precision Inc., we understand the nuances required to transform a client’s vision into tangible reality with utmost accuracy. Our CNC machinists are trained to deliver 100% precision, using state-of-the-art equipment to produce parts that defy the constraints typically associated with mass production. Such precision is imperative, especially in industries like aerospace and medical, where even the smallest deviation can have significant consequences.

The challenge lies in adapting traditional mass production techniques to suit bespoke manufacturing. Anco Precision excels in this area by leveraging advanced technologies such as CNC milling and CNC turning, which allow for the meticulous crafting of custom components. We have seen how our attention to detail significantly enhances the quality of unique auto parts, medical instruments, and even optical devices. Our commitment ensures that low volume production machining is a reliable solution for varied industrial needs.

Flexibility of Services

One of the standout aspects of Low Volume Production Machining at Anco Precision is the flexibility offered to our clients. Our services cater to a broad spectrum of manufacturing requirements, enhancing the ability to swiftly pivot and adapt designs. This flexibility is crucial in industries like robotics and electronics, where innovation is rapid, and designs frequently evolve. Customers appreciate our quick turnaround times, which are made possible by our capacity to manage diverse projects without compromising on quality.

For anyone requiring prototype parts, our rapid prototyping service is a game changer. It’s not just about speed; it’s about producing parts that perfectly align with design specifications, helping companies innovate faster and more efficiently. Our online quote system makes this process seamless, offering instant price estimates and the ability to kickstart production with just a few clicks.

Unleashing Creativity in Machining

Low Volume Production Machining opens up an exciting world of possibilities for creativity and innovation. At Anco Precision, we’ve witnessed how this approach empowers industries to push the boundaries of what’s possible, whether it’s the development of cutting-edge biotech devices or the crafting of unique marine tools. By eliminating the hefty costs and long lead times associated with traditional mass production, we allow designers and engineers to experiment with new ideas and refine prototypes with ease and agility.

Clients across various sectors, from product designers to aerospace engineers, benefit from our ability to deliver custom-tailored solutions. Our machinists’ expertise and commitment ensure that each piece is crafted with precision, turning even the most complex designs into reality. This creative freedom inspires clients to innovate continuously, knowing they have a reliable partner in Anco Precision.

In our experience, the success of Low Volume Production Machining lies in the delicate balance of precision, flexibility, and creativity. With over four decades of experience, Anco Precision Inc. stands at the forefront of this industry, committed to delivering unparalleled quality and service. Our dedication to excellence and customer satisfaction marks us as a preferred choice for bespoke machining needs.

What role do production machine shops play in modern manufacturing?

Production machine shops are pivotal in transforming raw materials into precise, high-quality components necessary for various industries. These shops utilize advanced machinery and techniques, such as CNC milling and turning, to produce parts that meet stringent specifications. At Anco Precision, with over 40 years of experience, we see ourselves as the backbone of many high-tech industries by ensuring each component is crafted to the highest standards. Our work supports sectors like aerospace and automotive, where accuracy and reliability are crucial.

If you’re curious about how these shops have evolved over time or specific machinery used, I’d love to dive deeper. What aspects of machine shops interest you the most?

How has technology innovation impacted machining capabilities?

Technological advancements have revolutionized machining capabilities, enhancing both efficiency and precision. At Anco Precision, we continuously integrate cutting-edge equipment to streamline our processes and improve accuracy. For instance, the adoption of rapid prototyping allows for faster project iterations without sacrificing quality. This has been a game-changer, especially for industries that require quick turnarounds.

The innovation doesn’t just stop at machinery. Our online platform that provides instant quotes is an example of how technology can simplify project planning and client collaboration. Have you encountered any new technologies in the field that have surprised you?

How important is customer service in a production machine shop?

Customer service is essential in a production machine shop because it directly influences client satisfaction and trust. At Anco Precision, we emphasize open communication and a commitment to meeting deadlines while maintaining quality. Our customer-centric approach ensures that every project is a collaborative effort, making us a trusted partner rather than just a service provider. It’s about building relationships that last, which results in repeat business and referrals.

Have you ever had an experience where exceptional customer service made a difference in your projects or purchasing decisions?

What are common misconceptions about precision in production machining?

One common misconception is that achieving high precision is solely reliant on advanced machinery. While technology plays a crucial role, the skills and expertise of machinists are equally important. At Anco Precision, our team undergoes rigorous training to ensure they can fully leverage state-of-the-art equipment to its potential. Precision is a blend of technology and human skill, creating components that meet even the most demanding industry standards.

Precision is often underestimated until you see a project where even a microscopic deviation matters, such as in aerospace applications. What are your thoughts on the balance between technology and skill in your industry?

Why is flexibility in services critical for low volume production machining?

Flexibility is essential in low volume production machining because it allows us to adapt to rapidly changing client requirements and designs. Industries like robotics and biotech are constantly innovating, and our ability to pivot quickly is a significant advantage. At Anco Precision, we offer services such as rapid prototyping, which enables fast adjustments and iterations, ultimately leading to innovation without the constraints of mass production.

This flexibility also aids in reducing lead times, providing clients with the agility needed to stay competitive. How do you incorporate flexibility into your processes or projects?

How does low volume production machining unleash creativity and innovation?

Low volume production machining allows for creative freedom by minimizing the risks associated with trial and error. At Anco Precision, we empower industries to experiment and refine prototypes rapidly, which opens up new possibilities in design and functionality. This approach is particularly beneficial in sectors like marine and aerospace, where unique solutions can lead to breakthroughs.

By reducing costs and lead times, our clients can focus on innovation rather than constraints. It’s about providing the tools and flexibility needed to turn concepts into tangible realities. In what ways do you think machining can foster innovation in your field?

Resources

- National Institute of Standards and Technology – Official website of NIST, providing resources on standards and technology.

- American Society of Mechanical Engineers – Website of ASME, offering information on mechanical engineering and industry standards.

- Cornell University College of Engineering – Homepage of Cornell University’s College of Engineering, featuring research and educational resources.

- National Science Foundation – Official website of the NSF, providing funding and research opportunities in science and engineering.

- Massachusetts Institute of Technology – Homepage of MIT, offering resources on engineering and technology advancements.