Benefits of Rapid Prototype Machining

At Anco Precision Inc., we understand the significant impact that Rapid Prototype Machining has on product development cycles. With over four decades in the industry, we’ve witnessed firsthand how rapid prototyping transforms ideas into tangible products swiftly. By allowing multiple iterations in a short time frame, this machining process empowers designers and engineers to refine their creations based on real-world insights. This agility not only accelerates time-to-market but also enhances product quality, ensuring our clients always stay ahead in their respective industries.

Rapid Prototype Machining is indispensable for industries demanding high precision and minimal tolerance for errors. For instance, our work with medical device manufacturers highlights the critical need for prototype accuracy, where even minor discrepancies can lead to significant issues. By leveraging cutting-edge CNC technologies, we deliver parts that not only meet but often exceed industry standards, showcasing our dedication to precision and quality. This meticulous approach is a testament to our commitment to excellence and customer satisfaction.

Materials and Methods

The versatility of Rapid Prototype Machining lies in its ability to handle a wide array of materials, from metals to plastics. At Anco Precision, our CNC machining capabilities cover everything from aluminum and stainless steel to advanced polymers, ensuring that regardless of the project’s requirements, we have the tools and expertise to deliver. This material flexibility is especially beneficial for sectors like aerospace and automotive, where custom materials often play a crucial role in product innovation.

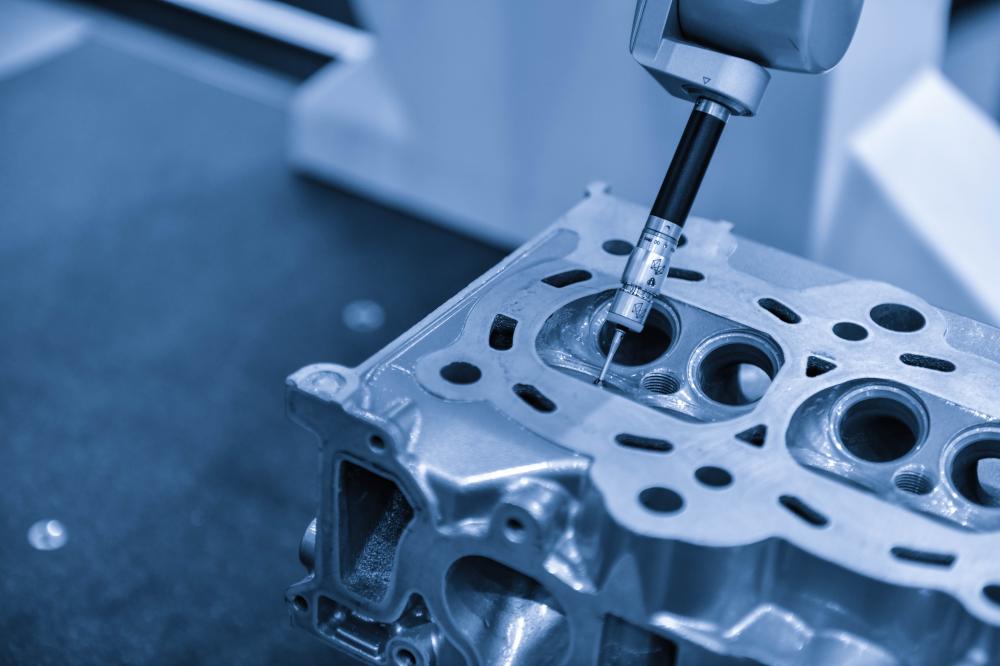

Among the many techniques we employ, CNC milling and turning stand out for their precision and efficiency. Our state-of-the-art equipment allows for detailed machining, even on the most intricate parts, ensuring our clients receive products that meet exact specifications. This precision is critical for components like auto engines and aircraft parts, where performance and safety are non-negotiable. Such attention to detail underscores our ability to cater to a broad range of industries, each with its unique set of standards.

Moreover, the inclusion of screw machining in our repertoire offers an additional layer of precision, essential for creating intricate threads and features on prototype parts. By combining these methods, Anco Precision ensures a comprehensive approach to Rapid Prototype Machining, empowering our clients to innovate with confidence.

Speed and Efficiency

Time is often a luxury in product development, and Rapid Prototype Machining acts as a time machine for innovators. At Anco Precision, we pride ourselves on quick turnaround times without compromising on quality. Our streamlined processes enable us to deliver prototypes swiftly, sometimes in less than a week. This agility is a vital asset for industries like consumer electronics, where speed to market can make or break a product’s success.

By offering instant quotes through our online platform, we further enhance the speed and efficiency of our services. Clients simply need to upload their drawing files, and within moments, they can receive detailed project estimates. This seamless interaction reduces the traditional back-and-forth typically associated with custom machining, ensuring that our clients can focus on what they do best–innovating and pushing boundaries.

Our efficiency in Rapid Prototype Machining doesn’t stop at production. Meticulous quality checks are integrated into every step, ensuring that each part not only meets but often surpasses the desired standards. Such dedication to speed and detail ensures that Anco Precision remains a trusted partner for companies looking to innovate without compromise.

Real-World Applications and Success Stories

Anco Precision’s legacy in Rapid Prototype Machining is rich with stories of success across diverse industries. A memorable project involved developing prototype components for a marine technology company, where the reliability of parts was paramount. By providing precise, high-quality prototypes quickly, we enabled our client to conduct rigorous testing and refine their designs, ultimately leading to a successful product launch.

Similarly, our partnerships with automotive companies have resulted in innovative breakthroughs. From custom car parts to entire engine assemblies, our prototypes allow for comprehensive testing and development, proving invaluable in an industry where precision and durability are critical. Our contributions to these projects underscore the transformative power of efficient and precise Rapid Prototype Machining.

Our clients’ feedback is a testament to the peace of mind that our services provide. They appreciate our commitment to delivering products that meet their exact requirements and our ability to exceed expectations with every project. This consistency has cemented Anco Precision as a go-to provider for companies seeking unmatched quality and service in the realm of Rapid Prototype Machining.

The Art of Prototype Machining

At Anco Precision Inc., we view Prototype Machining as a finely tuned art. With our extensive history in the CNC machining world, we’ve crafted techniques that blend traditional craftsmanship with modern technology. Our team, with decades of experience, can transform a concept into a tangible reality using cutting-edge equipment. This process ensures that whether we are working with metals, plastics, or synthetics, the final output maintains the highest standards of precision.

We often compare the journey of Prototype Machining to orchestrating a symphony: each step requires accuracy and timing to produce the perfect result. From an industry veteran’s perspective, it’s not merely about cutting and molding materials; it’s about visualizing the final product and executing each step with meticulousness. Every project we undertake is a new canvas, a new challenge, and an opportunity to push our creative boundaries.

Over the years, our clients have brought us everything from intricate medical devices to robust marine parts. The variety of projects keeps our workshop vibrant and our methods constantly evolving. Creating prototypes that meet diverse industry needs requires not just skill but also adaptability, both of which we have honed to perfection.

Precision and Detail in Action

At the heart of Prototype Machining lies an unwavering focus on precision. Every piece we manufacture must meet exact specifications, and achieving this requires a deep understanding of our tools and materials. Anco’s machinists are rigorously trained to handle our sophisticated machinery, which allows us to offer unparalleled accuracy and quality in our products.

Our clients often express amazement at our attention to detail–a cornerstone of our business. Each component we produce goes through rigorous quality checks to ensure it meets not just ours but also our clients’ high standards. This meticulous approach is what sets Anco Precision apart and contributes to our reputation as leaders in the industry.

Consider this: when working on projects for sectors like aerospace or medical technology, the slightest deviation can lead to significant issues. We know that the stakes are high, and our commitment is to deliver nothing short of perfection. This dedication to precision ensures that all our Prototype Machining projects are not only functional but also durable and reliable.

Our system is designed to streamline the entire process. With our instant quoting system, clients can simply upload their designs and receive a detailed quote quickly. This innovation saves time and allows our clients to make informed decisions promptly, facilitating smoother project progression.

Innovation and Expertise at Anco Precision

While the tools of Prototype Machining are essential, the real magic happens through innovative thinking and expertise-driven execution. At Anco Precision Inc., we celebrate innovation, encouraging our team to continually explore new techniques and tools that enhance our capabilities. By fostering a culture of continuous learning, our machinists are always at the forefront of industry advancements, ensuring we can offer cutting-edge solutions for our clients.

Our diverse clientele has pushed us to venture into unexplored territories, challenging our technicians to create unconventional and complex designs. By doing so, we have expanded our repertoire and strengthened our problem-solving skills. This proactive approach doesn’t just keep us ahead of the curve; it reinforces our commitment to excellence and innovation.

Every project tells a story–a story of creativity, collaboration, and culminated expertise. Whether it’s an inventor’s first prototype or a massive production for a government contract, each task is as important and exciting as the next. Our mission is to ensure that when partners approach Anco Precision, they leave with the conviction that they’ve made the right choice for their machining needs.

Precision Excellence in CNC Machining

At Anco Precision Inc., the heart of our operations lies in our commitment to precision excellence. With over four decades of experience, our family-owned Prototype Machine Shop in Deerfield Beach, FL, stands as a beacon of quality and innovation. Our seasoned machinists are the lifeblood of our operation, expertly trained to navigate the complexities of cutting-edge equipment to deliver astounding results. The unwavering attention to detail ensures that every product — whether it’s a custom car part or a complex medical instrument — meets the highest standards.

Our expertise extends across industries, from aerospace to automotive, ensuring that we cater to a wide array of manufacturing demands. Our services are diverse, yet unified by a single goal: achieving 100% precision. This dedication is what sets our Prototype Machine Shop apart and places us at the forefront of the CNC machining industry.

Services Tailored for Diverse Needs

At our state-of-the-art facility, we offer a comprehensive range of services that cater to a multitude of needs. Our specialization in CNC milling, CNC turning, rapid prototyping, and screw machining allows us to accommodate projects of various scopes and complexities. Each service is a testament to our commitment to quality and innovation, tailored to meet the unique specifications of every client.

Our customers repeatedly express their satisfaction with our quick turnaround times and competitive pricing. Whether it involves fabricating intricate enclosures for electronic devices or creating durable components for aircraft, we embrace every challenge with enthusiasm and expertise. Anco Precision Inc. is more than just a Prototype Machine Shop; it is a partnership in excellence, ensuring that your vision comes to life precisely as intended.

Moreover, our instant quote system simplifies the process, allowing customers to upload design files and receive immediate feedback. This streamlined approach not only saves time but also empowers our clients to kick-start their projects with confidence and clarity.

Real Experiences, Real Results

Throughout our journey, we have forged strong relationships with an eclectic clientele, ranging from individual inventors to government agencies. Each partnership is built on a foundation of trust and mutual respect, with our Prototype Machine Shop delivering unparalleled service and quality. These relationships are a testament to our dedication and ability to adapt to diverse challenges.

Our clients have consistently commended our professionalism and the rapid pace at which we deliver quality products. Their testimonials reflect our unwavering commitment to maintaining high standards, ensuring that every interaction is a positive and productive experience. These real-world stories of success are the backbone of our reputation, reinforcing our status as a reliable and innovative Prototype Machine Shop.

By constantly investing in our people and technology, we maintain an environment where creativity and precision thrive. This ongoing evolution ensures that Anco Precision Inc. remains a step ahead, ready to meet the ever-changing demands of the industries we proudly serve.

What are the key benefits of using rapid prototype machining in product development cycles?

As someone deeply involved in the machining industry, I can tell you that rapid prototype machining is a game changer in product development. This process allows designers to translate their ideas into tangible products swiftly, enabling multiple iterations in a short span. For instance, we’ve worked with medical device designers who need accurate prototypes to avoid even the slightest discrepancies that could affect patient safety. By using advanced CNC technologies, we deliver parts that not only meet but often exceed industry standards. This agility accelerates time-to-market and enhances product quality, ensuring our clients can stay ahead of the competition. Have you considered how quick iteration cycles might transform your product development process?

What types of materials can you work with in rapid prototype machining, and how do you choose the right one?

The beauty of rapid prototype machining is its versatility with materials. At Anco Precision Inc., we can work with everything from metals to plastics. Choosing the right material often depends on the specific use case. For example, in the aerospace industry, where custom materials often drive innovation, we might select a lightweight alloy for strength and efficiency. In contrast, a medical prototype might require a biocompatible polymer. Our CNC milling and turning techniques allow us to achieve high precision no matter the material, ensuring we meet the unique requirements of each project. What’s a material challenge you’ve faced, and how might diverse machining options help overcome it?

How does rapid prototype machining enhance speed and efficiency in the manufacturing process?

Time in product development can be crucial, and with rapid prototype machining, we essentially provide a fast-forward button for innovators. Our processes at Anco Precision are designed for quick turnaround without compromising quality. We’ve delivered prototypes in as little as a week, which is a huge advantage in fast-paced industries like consumer electronics. Additionally, our online instant quoting system reduces traditional back-and-forth communication, allowing clients to get detailed estimates quickly. This efficiency means clients can focus more on innovation and less on logistics. How do you think speeding up the prototype stage could impact your overall production timeline?

Why is precision considered the cornerstone of a reputable prototype machine shop?

Precision is not just a technical requirement–it’s at the heart of what we do at Anco Precision. In industries like aerospace and medical technology, even the smallest deviation can have significant consequences. Our team is rigorously trained to ensure that every product meets the highest standards. Consider the process like crafting a fine watch: every component needs to fit perfectly to ensure optimal performance. We integrate meticulous quality checks at every stage to ensure that what we deliver is both functional and reliable. Do you think focusing on precision could redefine the standards of your projects?

Resources

- NASA – Official website of the National Aeronautics and Space Administration, providing information on space exploration, aeronautics, and scientific discoveries.

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory agency that promotes innovation and industrial competitiveness by advancing measurement science, standards, and technology.

- Massachusetts Institute of Technology (MIT) – MIT is a world-renowned research university known for its cutting-edge research and education in science, engineering, and technology.

- National Science Foundation (NSF) – The NSF is a federal agency that supports research and education in all non-medical fields of science and engineering.

- American Society of Mechanical Engineers (ASME) – ASME is a professional organization that promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe.