Unique Advantages of Job Shop Machining

At Anco Precision Inc., job shop machining is not just a service; it’s a craft refined over decades of commitment and precision. Being a family-owned CNC machine shop has given us the flexibility to offer truly customized solutions. This flexibility is essential in industries like aerospace and medical devices where precision and customization are paramount. Having worked across these sectors, we’ve seen first-hand how our adaptability meets niche demands and builds long-lasting client relationships.

We’ve often found that small batch production is a key advantage in job shop machining. This method allows us to focus on each piece with unparalleled attention to detail. Our team’s proficiency in CNC milling and turning ensures that the products not only meet but often exceed client expectations. Notably, the ability to switch efficiently between projects is a hallmark of job shop machining that sets us apart from high-volume production lines.

The diversity of our services from rapid prototyping to screw machining demonstrates our commitment to meeting varied customer needs. Whether it’s custom car parts or specialized medical instruments, our job shop excels in offering bespoke solutions. This adaptability means we can serve a wide array of sectors with precision and efficiency unmatched in traditional manufacturing environments.

Intricacies of the Job Shop Process

The journey of creating a custom part at Anco Precision starts with a detailed client consultation. Here, we gather all necessary specifications and envision the final product. This is followed by a comprehensive quoting process, an area where our online machine shop shines by offering instant quotes from submitted drawings. This seamless process ensures that our clients have a clear understanding of their project’s scope and cost from the outset.

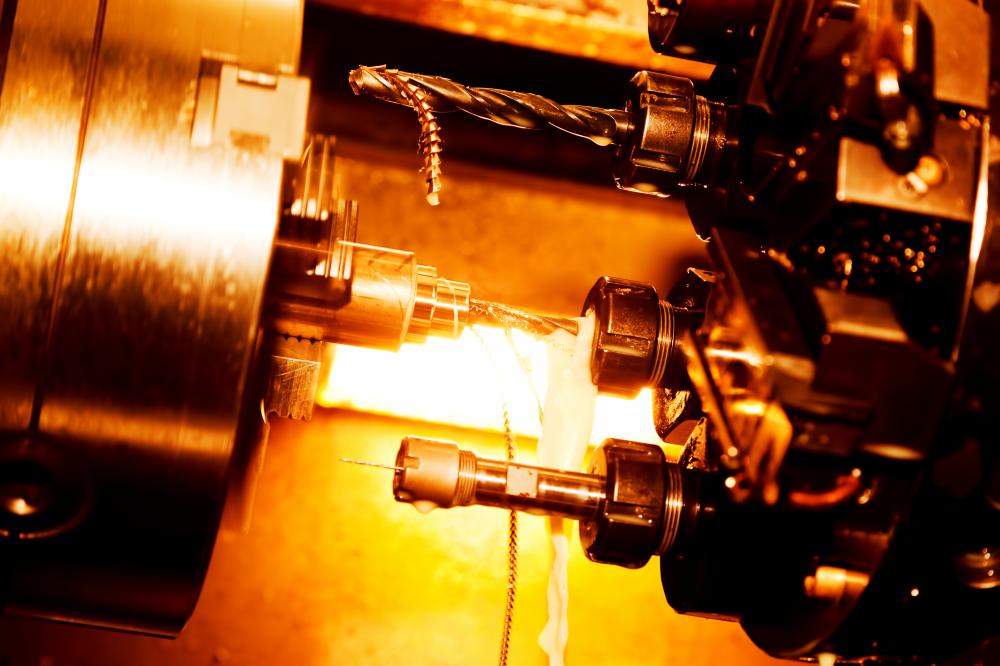

Once an order is confirmed, the real magic begins. Our machinists, trained on state-of-the-art equipment, dive deep into the fabrication phase. This involves using CNC technology to bring the design to life with exact precision. Our craftsmanship is not only about cutting and shaping but also about blending technology with skill to produce impeccable, precise outcomes. Each project is a testament to our dedication to detail and quality.

Quality control is an integral part of our operation. At every stage, rigorous testing ensures that the products adhere to the highest standards. Be it through the final assembly or finishing processes, our commitment remains unwavering. Each piece is crafted to perfection, reflecting our reputation for excellence in job shop machining.

Strategic Insights for Optimizing Operations

Managing a job shop requires a strategic blend of tradition and innovation. At Anco Precision, we have implemented dynamic scheduling systems to handle the variability intrinsic to job shop environments. Our systems allow us to adapt to changes in project scope and client demands seamlessly, keeping us ahead of potential disruptions.

For us, lean manufacturing strategies are not just practices but guiding principles. By minimizing waste and optimizing workflow, we maximize efficiency and pass these benefits to our clients in the form of competitive pricing. Cross-training our machinists is another strategy we employ, ensuring that our workforce is versatile and ready to tackle any challenge head-on.

Effective inventory management is another cornerstone of our operations. By employing just-in-time inventory practices, we maintain optimal levels of materials, thereby reducing costs and decreasing lead time. These strategies collectively enhance our job shop machining operations, making us a reliable partner for complex, customized manufacturing needs.

Utilizing advanced technologies such as ERP software has been pivotal for us. We integrate these systems to streamline processes from order to delivery, ensuring precision and efficiency at every step. The automation and data insights provided by these technologies empower us to continue delivering products that are both innovative and precise.

Operating with Precision

The heart of Anco Precision Inc. beats with the rhythm of accuracy. We take pride in our role as a leading CNC machine shop, dedicated to delivering high-quality production machining services. Our commitment to precision is not just a promise; it’s a practice that’s deeply embedded in our DNA. Each project we undertake is a testament to a meticulous level of detail that ensures every customer requirement is met with exactitude. Our machinists, who are experts in their field, undergo rigorous training to operate state-of-the-art equipment. Through their skill, we offer products that shine not only in craftsmanship but also in competitive pricing.

Our extensive experience, spanning over four decades, enables us to cater to a wide array of industries, including marine, automotive, medical, and aerospace. Each product that leaves our facility is a reflection of our unwavering dedication to quality and precision. From custom car parts to medical instruments, our expertise is vast and varied. We believe every product should stand up to the rigorous demands of its respective industry, and our team works tirelessly to see that vision realized.

Innovative Services We Offer

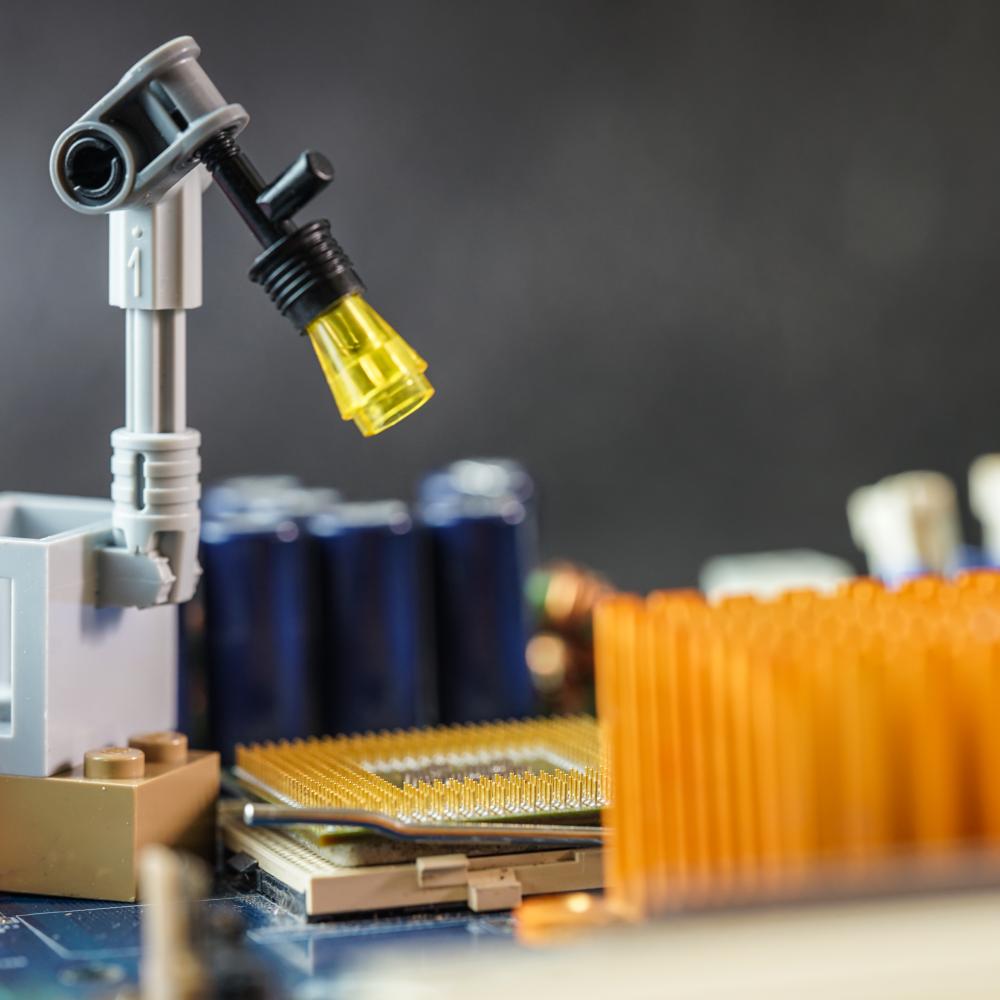

CNC Milling and Turning

At Anco Precision, our CNC milling and turning services are second to none. We have honed our processes to provide superior results for every project. Whether we’re crafting parts for electronic devices or creating components for aerospace applications, our focus remains on delivering precision-engineered products that exceed expectations. Our commitment to quality craftsmanship allows us to address a wide range of manufacturing needs while ensuring timely delivery and cost-effectiveness.

Rapid Prototyping and Screw Machining

In addition to CNC services, we specialize in rapid prototyping and screw machining. This allows us to support our clients from concept to creation, offering the flexibility to iterate and perfect designs with speed and efficiency. Our rapid prototyping services enable quick adjustments, helping innovators and designers bring their visions to life without unnecessary delays. Whether you’re developing a new model or refining an existing design, our team is equipped to provide practical solutions tailored to your unique requirements.

Our services are designed with the customer experience in mind. We offer instant quotes through our online machine shop, simplifying the process of starting a new project. By uploading a drawing file, clients can receive detailed quotes instantly, enabling them to move forward with confidence and clarity.

Testimonies of Excellence

Our commitment to excellence is reflected in the praise we receive from our clients. Testimonials speak to our exceptional service, quick turnarounds, and the consistent quality that defines Anco Precision as a trusted partner. Customers appreciate our attention to detail and our ability to deliver precisely what they need, when they need it. This reliability has earned us the reputation of a go-to CNC machine shop for various manufacturing needs.

Clients from diverse industries, whether government agencies, aerospace companies, or individual inventors, have expressed their satisfaction with the services we provide. Our ability to adapt and tailor our offerings to meet specific demands has been key to building lasting relationships with businesses of all sizes.

We welcome inquiries and invite potential partners to visit Anco Precision Inc. in Deerfield Beach, FL. Here, they can witness firsthand the dedication and craftsmanship that sets our machine shop apart. We are passionate about supporting innovation and helping our clients achieve success through precision machining.

Precision in Every Detail

When it comes to CNC machining, Anco Precision Inc. prides itself on delivering nothing short of perfection. Offering services such as CNC milling, CNC turning, rapid prototyping, and screw machining, our Local Job Shop aims to meet the unique needs of each client with meticulous attention to detail. Our commitment to quality ensures that we deliver products engineered with 100% precision, tailored to fulfill a wide range of specifications.

Our team consists of highly skilled machinists who have undergone extensive training to operate state-of-the-art equipment. This rigorous training guarantees that every project, whether it involves custom car parts or intricate medical instruments, receives the craftsmanship it demands. Our dedication to maintaining exceptional quality standards allows us to remain a trusted partner in the machining industry.

Our online platform facilitates a seamless experience for anyone needing a Local Job Shop. Clients can effortlessly submit their design files and receive instant quotes, making the process of initiating projects swift and efficient. This streamlined approach ensures that from concept to completion, every step is handled with the utmost professionalism.

Diversity in Industries Served

At Anco Precision Inc., we cater to a diverse array of industries, each presenting its own unique challenges and requirements. From aerospace companies to government agencies, our Local Job Shop extends its expertise to a broad spectrum of clients. Understanding the intricacies of different sectors allows us to offer solutions that not only meet but exceed expectations.

Collaborating with small and large businesses alike, as well as universities and product designers, we have the adaptability and knowledge to tackle projects of all scales. Our work with mechanics, inventors, and scientists further underscores our ability to push the boundaries of innovation and deliver products that truly make a difference.

Testimonials from satisfied customers highlight our consistent delivery of excellence. Feedback points to our quick deliveries, competitive pricing, and the unwavering quality of our products, reinforcing the trust and reliability we’ve built within the local job shop community. The ability to pivot and adapt to various industry needs is a hallmark of our service.

We’re not just a Local Job Shop; we’re a partner in progress, enabling our clients to achieve their goals seamlessly. As a family-owned business, we inject personal dedication into our professional operations, ensuring that our clients receive not only precision machining but also a human touch that makes every project special.

Customer Experience and Value

Seamless Communication and Support

Our customer service philosophy is rooted in transparent communication and unwavering support. As a Local Job Shop that values its clients, Anco Precision Inc. ensures that every interaction is handled with the utmost care and professionalism. We understand that clear communication is vital in delivering projects that meet client specifications and timelines.

Innovation and Continuous Improvement

Innovation is at the heart of our operations. By staying at the forefront of technological advancements, we provide cutting-edge solutions that cater to evolving industry demands. Our commitment to continuous improvement ensures that our Local Job Shop is always equipped to handle the latest challenges in manufacturing.

Cost-Effective Solutions

One of our core tenets is offering competitive pricing without compromising on quality. This balance allows us to serve a diverse clientele who seek value without sacrificing the precision and reliability they require. Our approach to cost-effectiveness positions our Local Job Shop as a favored choice among businesses looking for quality machining services.

What are the unique advantages of job shop machining?

At Anco Precision, Inc., job shop machining is truly distinctive due to our ability to provide highly customized solutions tailored to the specific needs of our clients. Unlike high-volume production lines, we excel at small batch production, which allows us to give each piece unparalleled attention to detail. This flexibility is a huge advantage in industries like aerospace and medical devices, where precision is non-negotiable. We’ve seen firsthand how our adaptability builds long-lasting relationships by meeting niche demands. If you’re considering moving to more versatile production capabilities, how might job shop machining fit into your operations?

What are the intricacies involved in the job shop machining process?

The job shop process at Anco Precision begins with a comprehensive client consultation to ensure we gather all necessary specifications for the final product. Our approach to quoting is seamless, thanks to our online machine shop offering instant estimates directly from submitted drawings. Once an order is confirmed, we use state-of-the-art CNC technology coupled with skilled craftsmanship to achieve exact precision. Quality control is integral at every stage, ensuring that each project reflects our dedication to excellence. How might improving the consultation and quoting processes benefit your production cycles?

How do job shops optimize operations to manage variability and complexity in projects?

Managing a job shop like Anco Precision requires a strategic blend of traditional practices and innovative solutions. We utilize dynamic scheduling systems to seamlessly adapt to changes in project scope and client demands, which is crucial in a variable environment. Lean manufacturing principles guide us in minimizing waste and optimizing workflow, which translates to competitive pricing for our clients. Cross-training our machinists ensures that our team remains versatile and prepared for any challenge. Moreover, advanced technologies, such as ERP software, streamline our processes from order to delivery, ensuring precision and efficiency. How do you currently balance tradition and innovation in your operations?

What does it mean to operate with precision in a job shop?

Operating with precision at Anco Precision is about more than just meeting specifications; it’s about exceeding them. Our commitment to precision is evident in the rigorous training our machinists undergo to master state-of-the-art equipment. Whether working on custom car parts or intricate medical instruments, we ensure every product reflects our meticulous attention to detail. This precision enables us to maintain competitive pricing while upholding our reputation for quality. When you think about precision in your own work, what areas do you see room for improvement?

What innovative services do job shops like Anco Precision provide?

At Anco Precision, our innovative services include CNC milling, CNC turning, rapid prototyping, and screw machining. These services are tailored to meet diverse manufacturing requirements with a focus on precision and timely delivery. Our rapid prototyping capabilities allow clients to iterate and perfect designs swiftly, supporting innovators from concept to creation. Additionally, our online platform provides instant quotes, simplifying the process for clients to initiate projects. What new services could help your business remain competitive and innovative?

How do customer testimonials reflect the quality of job shop machining services?

Our client feedback at Anco Precision is a testament to the exceptional service and quality we consistently deliver. Testimonials frequently highlight our attention to detail, quick turnarounds, and reliable service. Clients from diverse industries appreciate our ability to adapt and tailor our offerings to meet specific demands. This reliability has earned us a reputation as a trusted partner in the machining world. How do you gather and use customer feedback to enhance your services?

How does attention to detail influence the quality of job shop machining products?

Attention to detail is paramount at Anco Precision. Every project, from custom auto parts to sensitive medical instruments, is approached with meticulous care. Our skilled machinists ensure each product is crafted to perfection, meeting the exact specifications required. This commitment to detail ensures we deliver products that are not only of high quality but also meet rigorous industry demands. How might a focus on detail enhance the quality and reputation of your products?

How does a job shop cater to a diverse range of industries?

At Anco Precision, our diverse industry expertise allows us to serve clients ranging from aerospace companies to government agencies. Understanding the unique intricacies of different sectors enables us to provide solutions that not only meet but often exceed expectations. Our adaptability is key to tackling projects of varying scales, reinforcing our role as a reliable partner in innovation. What industry-specific challenges do you face, and how could a job shop help address them?

How do job shops enhance customer experience and offer value?

Enhancing the customer experience at Anco Precision starts with transparent communication and unwavering support. We prioritize clear interactions to ensure projects meet client specifications and timelines. Our commitment to innovation keeps us at the forefront of technology, enabling us to offer cutting-edge solutions. Balancing competitive pricing with quality ensures that we deliver value without compromising on precision. In your opinion, what aspects of customer interaction are most important in building strong client relationships?

Resources

- National Institute of Standards and Technology (NIST) – The NIST website provides valuable information on standards, technology, and innovation to support various industries.

- Aerospace Industries Association (AIA) – The AIA website offers insights into the aerospace industry and promotes policies that benefit aerospace manufacturers and suppliers.

- National Institutes of Health (NIH) – The NIH website is a leading resource for medical research, health information, and funding opportunities.

- American Society of Mechanical Engineers (ASME) – ASME provides resources for mechanical engineers, including codes and standards, conferences, and publications.

- National Academy of Sciences – The National Academy of Sciences website offers authoritative research and information on science, engineering, and health.