Precision Machining Florida: Family Values in Every Turn

Here at Anco Precision Inc., the art of machining blends seamlessly with family values, making every project as personal as it is professional. With over 40 years in the industry, our family-owned shop in Deerfield Beach has become synonymous with the precision machining that Florida demands. The heart of what we do is not just about the turning of machines but about the turning of ideas into reality.

Our team’s dedication is not just taught; it’s ingrained through generations. I remember standing in the shop as a child, watching my father craft parts with meticulous care. Those lessons have resonated throughout the decades, shaping how we approach every piece we produce. Whether it’s a custom car part or a medical instrument, the promise remains the same: unmatched precision.

Our reputation is built on delivering high-quality products across diverse industries, including marine, automotive, medical, and aerospace. Customers speak of us like family, not just from our friendly interactions but because they see the legacy and passion in every detail we execute.

State-of-the-Art Technology in Machining

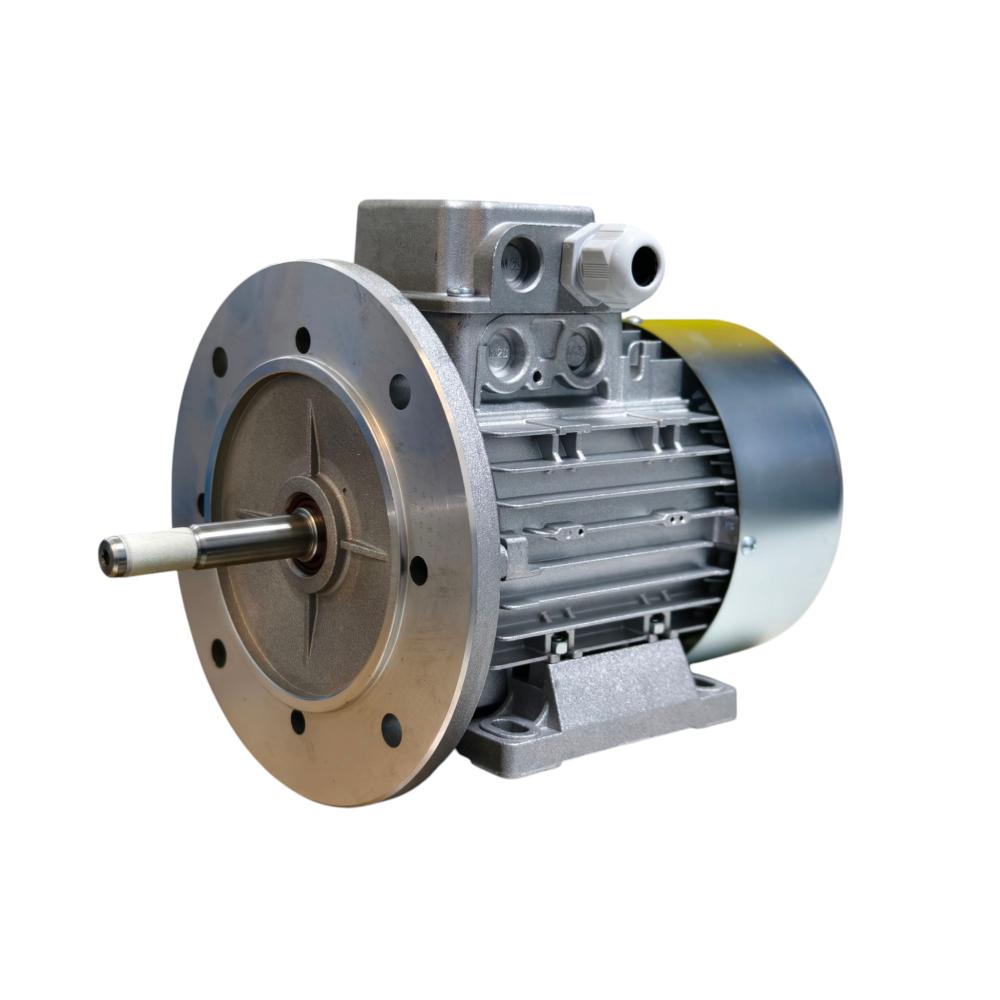

Precision is not just a goal; it’s a promise and requires the best in technology. We’ve always believed that to lead in Precision Machining Florida, one must never fall behind in tech. Our state-of-the-art equipment, including CNC milling and turning machines, ensures we consistently meet the rigorous quality standards our clients expect.

I often recall an instance where a client needed a rapid prototyping service with an impossible deadline. Thanks to our cutting-edge 3D modeling software and the expertise of our machinists, we were able to deliver not just on time, but with unrivaled quality. Such instances highlight why staying ahead with technology is crucial, not just for us, but for maintaining the standard of precision machining Florida has come to expect.

Diverse Capabilities and Customer Trust

Our capabilities extend far beyond just machining. Whether it’s CNC screw machining or high-tolerance turning, every service is rooted in decades of honing our craft across numerous industries. We offer an extensive range of services, such as crafting parts for aircraft and watercraft, and even more specialized entities like optical devices and robots.

We’ve often said that the real measure of success is customer trust. From individuals to large corporations, our clients return because they trust us to deliver consistent quality and precision. Our quick turnaround times, competitive pricing, and attention to detail are not just service aspects; they’re commitments we uphold every day.

Our instant online quoting system is another testament to how we blend traditional craftsmanship with modern convenience. Clients can simply send us a drawing file and receive a detailed quote, streamlining the process and speeding up project initiation. This service embodies our dedication to being not just a machine shop, but a comprehensive partner in precision machining Florida needs.

Making a Difference through Precision

It’s often said that the devil is in the details, and at Anco Precision, we find our delight there. Our attention to detail and commitment to perfection have earned us high praise across various industries. We serve not just industries, but also educational institutions and government agencies, proving that our capabilities know no bounds.

Our work is a blend of passion, precision, and a promise. It’s what sets us apart in the bustling scene of precision machining Florida offers. Knowing that a product we’ve crafted can play a part in cutting-edge technology or medical innovation is what drives us every day.

To those who need a partner they can rely on, Anco Precision stands ready, as we have for the past 40 years, to take on projects with the same fervor and commitment that built our family’s legacy–one precise turn at a time.

The Foundations of Precision Machining

As a family-owned CNC machine shop operating for over four decades, we at Anco Precision Inc. have seen the transformative impact of Precision Machining on various industries. This process, vital for creating components with tight tolerances, has revolutionized sectors like automotive, aerospace, and medical by ensuring high accuracy and repeatability in manufacturing. Precision Machining isn’t just a technique; it’s the backbone of modern engineering, enabling innovations that were once thought impossible.

At its core, Precision Machining is about removing material carefully and accurately from a workpiece to achieve the desired design, often relying on CNC technology. Our team, equipped with state-of-the-art CNC mills and lathes, crafts parts with exceptional attention to detail. This approach not only allows for the production of intricate parts but also ensures that each piece meets stringent quality standards. We take pride in each precisely machined component that leaves our facility in Deerfield Beach, FL.

Exploring Techniques in Precision Machining

CNC Milling and Turning

One of the techniques we specialize in is CNC milling, where rotary cutters systematically remove material. This method is crucial when working with complex 3D parts requiring meticulous detail. Meanwhile, CNC turning complements this by centering workpieces on a lathe, allowing for the creation of symmetrical components. Both methods demand a deep understanding of material properties and precise control–skills honed by our machinists over years of hands-on experience.

Rapid Prototyping and Screw Machining

Rapid prototyping is another vital component of Precision Machining. In today’s fast-paced market, the ability to quickly create and test prototypes is invaluable. It allows engineers and designers to iterate rapidly, refining their designs with each cycle. Our screw machining capabilities further enhance this by producing highly detailed components in bulk, making it an ideal solution for industries that demand high-volume production.

Throughout our journey in the industry, our commitment has been to not only understand but also anticipate our customers’ needs. By continuously updating our machinery and processes, we ensure that our services remain at the forefront of the Precision Machining field.

Impact of Precision Machining Across Industries

The application of Precision Machining extends well beyond simple manufacturing. In the realm of medical instruments, for instance, the precision we achieve means the difference between successful surgeries and compromised health outcomes. Components for surgical tools and diagnostic machines require the kind of exactitude that only Precision Machining can provide, and we’ve been privileged to contribute to advancements in this field.

In the aerospace industry, every component must withstand extreme conditions. Precision Machining ensures the reliability and performance of parts that must operate flawlessly. The trust placed in us by our aerospace partners speaks volumes about the confidence they have in our capabilities.

Our work in the automotive sector illustrates another facet of how Precision Machining can drive innovation. Custom car parts we produce not only enhance performance but also push the boundaries of automotive design. The precision involved in creating engine components and other critical parts underscores our commitment to excellence.

We believe the key to our success in delivering outstanding results lies in our partnership approach. By working closely with our clients, we ensure that every project meets their specific requirements, balancing cost-efficiency with uncompromised quality. Precision Machining is more than a service we provide; it’s a passion for perfection that drives every aspect of our operation.

Precision in Every Turn

As a staple in the Deerfield Beach community for over four decades, Anco Precision Inc. is where precision meets perfection. When people search for Precision CNC Machining Near Me, they often find our doors open, ready to transform ideas into flawless components. Our CNC turning services are not just about shaping metal; they’re about sculpting solutions to complex challenges. Our machinists, armed with state-of-the-art equipment, ensure that every turn, every cut, and every drill is executed with unparalleled precision, making us a preferred choice in the industry.

Our team has honed its skills across a spectrum of industries, from aerospace to medical devices, where precision is not just a requirement but a necessity. We’ve crafted parts for custom car engines and medical instruments alike, demonstrating that no project is too big or too small. When clients walk through our doors, they bring visions that we help mold into reality. That’s why when Precision CNC Machining Near Me is mentioned, our name often follows closely behind.

Having worked closely with inventors, engineers, and designers, we’ve learned that precision is more than just a measurement–it’s the promise of quality and reliability.

Advanced Solutions for Diverse Needs

Innovative Machining Techniques

We don’t just follow trends; we set them. At Anco Precision, our commitment to innovation drives us to adopt advanced machining techniques that push the boundaries of what’s possible. Through rapid prototyping and CNC milling, we bring speed and accuracy to the forefront, ensuring projects move swiftly from concept to completion. Whether you require a single prototype or mass production, our solutions are tailored to meet diverse machining needs with exceptional precision.

The quest for finding Precision CNC Machining Near Me often leads to our doorstep because of the myriad services we offer. From screw machining for detailed parts to CNC turning for intricate designs, we adapt our processes to meet the exact specifications required by our clients. Each project at Anco Precision is an opportunity to apply our engineering acumen and create something remarkable.

Proven Expertise and Experience

Our legacy in the machining world is built upon years of proven expertise and a commitment to exceeding client expectations. Customers from diverse industries, ranging from government agencies to product designers, trust Anco Precision for our deep industry knowledge and the ability to deliver consistent, high-quality outcomes. This trust is reflected in repeated searches for Precision CNC Machining Near Me that highlight our reputation for excellence.

At Anco Precision, we embrace every challenge as an opportunity to demonstrate our unwavering dedication to precision and quality, ensuring that each component we create stands the test of time.

Streamlined Processes and Customer Satisfaction

Customer-Centric Approach

Our customer-centric approach is at the heart of everything we do at Anco Precision. We believe in not just meeting but exceeding customer expectations by delivering high-quality components with a keen eye for detail. When people search Precision CNC Machining Near Me, they find a company deeply rooted in building long-lasting relationships through exceptional service and support. Clients can easily submit drawing files through our online platform and receive instant quotes, making the process seamless and efficient.

Embracing Precision in Every Interaction

The process of delivering precision goes beyond just the machines; it’s about every interaction, every conversation, and every commitment we make to our customers. Our dedicated team is always available to answer questions, provide insights, and ensure that every project is executed flawlessly. This dedication to customer satisfaction is why time and time again, people seek out Precision CNC Machining Near Me and choose Anco Precision as their trusted partner.

By intertwining meticulousness with efficiency, Anco Precision has carved a niche in the CNC machining world–where quality and satisfaction go hand in hand.

What makes precision machining essential across various industries in Florida?

Precision machining is vital because it allows us to manufacture components with exact specifications, ensuring reliability and performance. In industries like aerospace and medical, where the margin for error is minimal, our precision machining capabilities provide the quality assurance needed to meet strict industry standards. For example, we once partnered with a local aerospace firm to produce parts for an aircraft landing gear system, where precision was crucial for safety and operational efficiency. This level of detail in manufacturing is not just about meeting industry expectations; it’s about exceeding them by providing components that contribute to groundbreaking innovations. Have you considered how precision can elevate your project’s success?

How does Anco Precision Inc. balance traditional craftsmanship with modern technology in its machining processes?

At Anco Precision, we’ve perfected the blend of time-honored craftsmanship and cutting-edge technology. Our machinists are skilled artisans who combine their deep understanding of materials and machining techniques with the latest in CNC technology. With over 40 years in the industry, we’ve learned that while state-of-the-art machinery, like our CNC mills and lathes, offers precision and efficiency, it’s the knowledge and experience of our team that truly bring those machines to life. I remember working on a custom auto part using a CNC machine, and despite the complexity of the design, our team’s expertise ensured the final product was flawless. Are there areas in your work where a similar blend of tradition and technology could be beneficial?

What are the common misconceptions about precision CNC machining services in local areas like Deerfield Beach?

One common misconception is that high precision always comes at a high cost. In reality, while precision machining does require investment in quality tools and skilled labor, it often leads to cost savings in the long run. For instance, using our precision CNC services can reduce material waste and production errors, saving both time and money. Another misconception is that CNC machining is only for large production runs. In fact, our services cater to varied production needs, from a single prototype to full-scale manufacturing. An interesting scenario happened when we helped a local inventor create a prototype for a medical device, demonstrating how accessible precision machining can be even for small projects. What other misconceptions have you encountered in your industry?

How does Anco Precision ensure customer satisfaction throughout the machining process?

Customer satisfaction is at the core of everything we do at Anco Precision. Our approach is both proactive and responsive, allowing us to understand and anticipate our clients’ needs. We start with a detailed consultation to fully grasp project specifications and expectations. An example from my experience is when a client in the marine industry needed urgent modifications to a part design; our team quickly adjusted the plan and delivered the revised part efficiently. Our online quoting system simplifies the initial process, and our ongoing communication throughout production ensures transparency and trust. How do you engage with your clients to maintain satisfaction and loyalty?

Resources

- National Institute of Standards and Technology – Official website of NIST providing standards, measurements, and technology information.

- NASA – Homepage of the National Aeronautics and Space Administration, offering information on space exploration and aeronautics.

- Massachusetts Institute of Technology – Official website of MIT, a prestigious research university known for its cutting-edge technology and innovation.

- National Library of Medicine – Website of the NLM providing valuable resources on medical research and information.