Precision in Every Cut

At the heart of CNC Services Florida lies Anco Precision Inc., a family-operated machine shop renowned for its meticulous approach to manufacturing. With over 40 years of expertise, this Deerfield Beach-based company serves a wide array of industries, from medical to aerospace, with unparalleled precision. The dedication to detail ensures that each piece they produce meets stringent customer expectations, affirming their position as a leader in the CNC machining world.

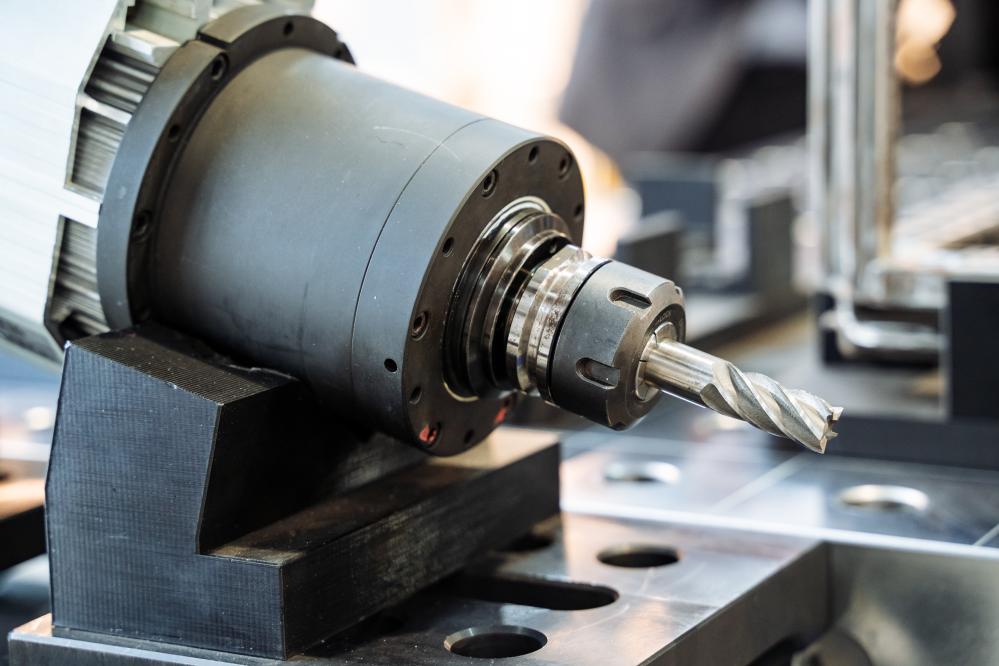

Having navigated the complexities of diverse sectors, Anco Precision’s experienced team brings decades of knowledge to the table. Their skilled machinists utilize state-of-the-art equipment, promising products that not only meet but exceed industry standards. Whether you’re in search of CNC milling or turning, their versatile services cater to all your needs.

Clients from various backgrounds, including marine and automotive industries, have consistently chosen Anco Precision for their reliability. The company’s commitment to delivering exceptional results is mirrored in the positive testimonials praising their quick turnaround times and competitive pricing.

Unmatched Versatility in Services

Anco Precision Inc. offers an impressive range of CNC machining services to suit the varied demands of CNC Services Florida. From CNC milling to rapid prototyping and screw machining, they stand ready to meet the unique needs of each project. Their capabilities extend to creating custom car parts, crafting components for aircraft and watercraft, and even producing medical instruments with precision.

For those requiring prototypes, Anco Precision simplifies the process with their online machine shop, allowing customers to receive instant quotes by submitting their designs. This streamlined approach allows designers, engineers, and inventors to quickly bring their visions to life, ensuring no time is wasted in development.

- CNC Milling: Precision cutting of diverse materials.

- CNC Turning: Ideal for creating symmetrical objects.

- Rapid Prototyping: Fast-track your ideas from concept to reality.

- Screw Machining: Delivering complex, precise parts.

Client-Focused Quality

Beyond their technical prowess, Anco Precision Inc. prioritizes the client experience. Every inquiry is met with a responsive, friendly touch that reflects their family values. Open from Monday to Friday, their team is always ready to address questions, provide quotes, and discuss project specifics to ensure satisfaction.

Clients appreciate the honest pricing and high-quality materials sourced for each job. By treating every project with the same level of importance, Anco Precision has built a loyal customer base across various sectors, from government agencies to individual inventors seeking reliable CNC services Florida.

Whether it’s for a university research project or a full-scale production run, Anco Precision is committed to ensuring every task is completed with exacting standards. Their consistent quality assurance and dedication to customer satisfaction make them a standout choice for those needing CNC services Florida.

Bridging Gaps in Industries

Anco Precision thrives on the diversity of the industries they serve. Whether it’s aerospace components or medical instruments, their expertise spans across various fields, tackling complex manufacturing challenges head-on. Their work is a testament to their ability to adapt and innovate, ensuring each client’s specific requirements are met with precision.

The impact of Anco Precision’s work reaches beyond just products; it’s about building relationships. By partnering with universities, schools, and labs, they play a crucial role in advancing scientific and technological projects. This collaborative approach not only elevates their profile but also contributes to the broader community of CNC Services Florida.

For anyone seeking reliable CNC services Florida, Anco Precision’s seamless integration of expertise, quality, and client-focused strategies demonstrates why they remain a trusted partner in the machining landscape. Their address at 3191 SW 11 ST Bldg 200 serves as a hub where innovation meets industry, crafting solutions that power progress across sectors.

The Essence of CNC Services

CNC Services have revolutionized the manufacturing landscape, enabling precision and efficiency that were once unimaginable. At the heart of this innovation is the ability to transform digital designs into tangible products with incredible accuracy. Central to this process is the use of computer numerical control (CNC) machines, which follow pre-programmed sequences to carve out components from raw materials like metal and plastic. Through Anco Precision Inc., a family-owned shop that has honed its craft over 40 years, companies in diverse sectors such as marine, automotive, and aerospace benefit from high-quality production machining.

Anco Precision’s legacy in CNC Services is characterized by its commitment to 100% precision and attention to detail. This approach ensures that every piece manufactured meets exact specifications, which is crucial in fields where safety and reliability are paramount. By employing state-of-the-art equipment and skilled machinists, they guarantee that all projects, whether a custom car part or a medical instrument, match the client’s vision and functional needs.

Advanced Techniques and Materials

CNC milling and CNC turning are core techniques within CNC Services that Anco Precision excels in. These processes allow for the creation of complex components with tight tolerances, which are essential for industries requiring high degrees of accuracy. CNC milling involves the removal of material from a workpiece with rotary cutters, while CNC turning revolves around the rotation of the material itself, allowing for intricate cylindrical shapes.

The choice of material is a critical aspect of CNC machining, and Anco Precision offers an extensive range of both metals and plastics to cater to specific requirements. Their expertise spans from working with durable metals like aluminum and titanium to engineering plastics like ABS and PEEK. This wide array of materials ensures that the finished products not only meet aesthetic and functional needs but also endure the rigors of their intended environments.

Beyond the standard offerings, Anco Precision’s CNC Services can also accommodate custom requests for specialized materials. By utilizing their network of trusted suppliers, they ensure that even the most unique projects receive the best possible material for the job.

One unique aspect of Anco Precision’s CNC Services is their rapid prototyping capability. This service allows for the quick turnaround of prototypes, enabling designers and engineers to test and refine their concepts efficiently before full-scale production. This aspect is particularly beneficial for industries such as medical devices and consumer electronics, where innovation is fast-paced and highly competitive.

Customer Experience and Satisfaction

Anco Precision Inc. prides itself on a customer-centric approach, ensuring that every client receives personalized service tailored to their specific needs. Their dedication to meeting deadlines, coupled with competitive pricing, has garnered them a reputation as a reliable partner in the machining industry. Testimonials from previous clients highlight the excellent service, quick deliveries, and consistent quality that Anco Precision offers.

One notable feature of their CNC Services is the instant quoting system provided through their online machine shop. By allowing customers to submit drawing files and receive detailed quotes immediately, Anco Precision streamlines the initial stages of project development. This efficient process reduces lead times and helps customers make informed decisions quickly.

Operating out of Deerfield Beach, FL, Anco Precision continues to forge strong relationships with government agencies, aerospace firms, and individuals alike. Their commitment to quality and customer satisfaction makes them a standout choice for anyone in need of precise and dependable CNC Services.

Aluminum CNC Services: Benefits and Applications

Aluminum CNC Service is a cornerstone of modern manufacturing, offering unparalleled precision and versatility. At the heart of many industries, aluminum’s lightweight yet robust nature makes it an ideal choice for diverse applications. Those involved in the aerospace, automotive, and medical sectors frequently rely on aluminum for its excellent strength-to-weight ratio and adaptability. With its extensive experience in providing Aluminum CNC Service, Anco Precision Inc. stands out by delivering high-quality, meticulously crafted components tailored to meet specific industry requirements.

In my years of collaborating with Anco Precision, I have witnessed firsthand the unwavering commitment they bring to every project. The machinists at Anco aren’t just operators; they are craftsmen who take immense pride in their work. Each part that leaves their shop reflects a deep-seated dedication to precision and quality–qualities that are vital when dealing with intricate components in critical industries.

A Specialized Approach to Aluminum CNC Service

Aluminum CNC Service at Anco Precision Inc. encompasses an array of techniques, each designed to meet a specific manufacturing need. Their expertise in CNC milling allows for the creation of complex geometries, while CNC turning offers precision for cylindrical components. The capability to engage in rapid prototyping ensures that even the most avant-garde designs are brought to life with efficiency and detail.

When you choose Anco for your Aluminum CNC Service needs, you’re not just opting for a machine shop–you’re choosing a partner committed to your project’s success. This commitment manifests in the form of competitive pricing, quick turnaround times, and a willingness to accommodate unique design specifications. Customers consistently commend the team for its responsiveness and the ability to deliver products that exceed expectations.

As a professional in the industry, I’ve noticed a significant trend towards customization, a need that Anco Precision is exceptionally well-equipped to fulfill. Whether it’s crafting custom car parts or creating precision medical instruments, their bespoke services ensure that each customer receives parts that perfectly match their unique requirements.

Enhancing Customer Experience Through Innovation

The process of securing Aluminum CNC Service can often be seen as daunting, particularly for those new to the manufacturing landscape. Anco Precision simplifies this experience through innovative solutions like their instant online quoting tool. By submitting a drawing file, customers can quickly receive detailed quotes, enabling a swift transition from concept to creation.

Understanding the importance of clarity and ease of service, Anco provides transparent communication every step of the way. Whether discussing potential design improvements or providing updates on production timelines, their open channels of communication foster a trust-based relationship with clients. This transparency is pivotal when navigating complex manufacturing projects, as it allows for adjustments and refinements in real-time.

Their Deerfield Beach facility becomes more than just a machine shop–it’s a hub of collaboration and innovation. Visitors are greeted not just by state-of-the-art equipment but also by a team genuinely invested in the success of every project. The human touch that Anco Precision brings, blending high-tech solutions with personal service, is a rare commodity in today’s industrial landscape.

Understanding the Importance of Precision in CNC Services

Why is precision such a critical element in CNC services, and how does Anco Precision ensure this in their processes?

Precision is the backbone of CNC services because it directly impacts the functionality and reliability of the final product, especially in industries like aerospace and medical, where even the smallest deviation can have significant consequences. At Anco Precision, we uphold a meticulous approach to every project, supported by over 40 years of expertise. Our machinists are trained to utilize state-of-the-art equipment, ensuring each component meets exact specifications. This dedication to detail guarantees that our products are not only compliant with industry standards but often exceed them, providing peace of mind to our clients. Precision ensures that our clients’ designs come to life exactly as envisioned, reinforcing trust and satisfaction in our services.

Versatility in CNC Machining Services

How does Anco Precision cater to the diverse needs of different industries with its CNC machining services?

The beauty of CNC machining lies in its versatility, and at Anco Precision, we pride ourselves on offering a wide range of services to meet the varied demands of our clients. From CNC milling and turning to rapid prototyping and screw machining, our capabilities are broad. For instance, when working with the automotive industry, we might be tasked with producing complex custom car parts, while the aerospace sector may require precision components for aircraft. Our team’s ability to adapt to each project’s unique requirements, coupled with our access to a wide array of materials–from aluminum to specialized plastics–allows us to deliver tailored solutions that meet specific industry needs. This adaptability is a cornerstone of our commitment to client satisfaction and quality craftsmanship.

Emphasizing Client-Focused Quality

What measures does Anco Precision take to ensure a client-focused approach in their CNC services?

At Anco Precision, we believe that a client-focused approach is essential to building long-lasting relationships. From the moment a client reaches out, we prioritize responsiveness and transparency. For example, we offer instant quotes through our online machine shop, which streamlines the initial stage of project development and allows clients to make informed decisions quickly. Our team is available to discuss project specifics, ensuring that we understand and meet every client’s needs. Furthermore, our honest pricing and commitment to using high-quality materials enhance our trustworthy reputation. By treating each project, whether small or large, with the same level of importance, we have cultivated a loyal customer base that appreciates our dedication to quality and service.

Exploring Aluminum CNC Services

What makes aluminum a preferred choice in CNC services, and how does Anco Precision excel in working with this material?

Aluminum’s combination of lightweight properties and robust strength makes it a favored material across various industries such as automotive, aerospace, and medical. At Anco Precision, our extensive experience with aluminum CNC services allows us to harness these qualities to produce high-quality, precise components tailored to specific applications. Our expertise in techniques like CNC milling and turning ensures that we can create intricate designs with tight tolerances. Additionally, our rapid prototyping capabilities facilitate quick and efficient testing and refinement of aluminum parts, enabling our clients to innovate with confidence. By offering competitive pricing and quick turnaround times, we ensure that our aluminum CNC services stand out as reliable and efficient.

Enhancing Customer Experience Through Innovation

How does Anco Precision leverage innovation to improve the customer experience in CNC services?

Innovation is at the core of how we enhance customer experience at Anco Precision. Our instant online quoting tool is an example of this commitment to innovation. By allowing customers to submit drawing files and receive detailed quotes swiftly, we reduce lead times and streamline the process from concept to creation. Furthermore, our open communication policy ensures that clients are kept in the loop at every project stage, allowing for real-time adjustments and fostering a collaborative environment. This approach not only simplifies the experience for our customers but also builds trust and ensures the successful completion of their projects. We invite our clients to explore how these innovations can meet their unique needs and elevate their overall experience with CNC services.

Resources

- National Institute of Standards and Technology (NIST) – NIST is a government agency that promotes innovation and industrial competitiveness by advancing standards and technology.

- Machining Cloud – Machining Cloud is an educational resource for the manufacturing industry, providing valuable information on machining processes and technologies.

- Engineering.com – Engineering.com offers a wealth of information on engineering practices, including CNC machining and precision manufacturing.

- Cimatron – Cimatron is a software company specializing in CAD/CAM solutions for the manufacturing industry, offering tools for CNC machining and more.

- Manufacturing USA – Manufacturing USA is a network of public-private partnerships aimed at advancing innovation in manufacturing and fostering collaboration among industry, academia, and government.