Precision in the CNC Manufacturing Company

At the heart of any CNC Manufacturing Company lies precision, a fundamental element that drives the industry forward. With over four decades in the field, Anco Precision Inc. stands as a testament to this commitment, delivering impeccable machining service to various sectors including marine, automotive, and aerospace. The dedication to precision is seen in every custom car part, medical instrument, or aerospace component produced, ensuring flawless execution to meet the rigorous standards demanded by clients.

Having worked with Anco Precision, I’ve witnessed firsthand the meticulous approach the team takes. The machinists undergo extensive training to master the state-of-the-art equipment, ensuring each piece is crafted to exact specifications. This focus on precision doesn’t just satisfy client needs but also enhances overall manufacturing efficiency, reducing waste and honing productivity.

Diverse Industry Applications

The strength of a leading CNC Manufacturing Company is its versatility in catering to multiple industries. Anco Precision shines in this aspect, with its ability to provide services for industries ranging from government agencies to individual inventors. Whether dealing with complex aerospace designs or creating prototypes for budding inventors, the company’s expertise is evident in its diverse project portfolio.

This versatility stems from the range of services Anco offers, such as CNC milling, CNC turning, and rapid prototyping. These capabilities are essential for producing intricate parts for robotics, electronics, and even optical devices. Clients often praise the quick turnaround times and competitive pricing Anco offers, a testament to their efficiency and commitment to client satisfaction.

My experience with Anco Precision confirmed that their extensive industry experience translates into real-world benefits for clients. Testimonials highlight the company’s ability to deliver not just parts, but also peace of mind, knowing that each project is handled with the utmost professionalism and care.

Advanced Machining Capabilities

A CNC Manufacturing Company like Anco Precision is defined by its advanced machining capabilities. Specializing in CNC milling, turning, and screw machining, Anco has cemented its reputation for delivering high-quality machining solutions. The ability to produce both one-off prototypes and high-volume production runs with equal adeptness is a hallmark of Anco’s service offerings.

One notable feature is their ability to offer instant quotes through an online platform, making it easy for clients to initiate projects. This digital streamlining is particularly beneficial for designers and product developers who need rapid feedback on project feasibility and cost implications. By leveraging digital tools, Anco combines traditional manufacturing excellence with modern convenience.

Customer-Centric Approach

What sets a CNC Manufacturing Company apart is not just technical prowess but a customer-centric approach to business. Anco Precision exemplifies this through their personalized service and dedication to understanding customer needs. Operating Monday to Friday, Anco ensures accessibility for clients seeking rapid prototyping or production solutions.

Clients frequently commend the team’s willingness to collaborate and adjust to specific project requirements. Whether it’s through in-person consultations or digital engagements, the focus remains on delivering exceptional customer service. Anco’s ability to cater to both large contracts and individual entrepreneurs speaks to their adaptability and commitment to client success.

Having collaborated with Anco, I can affirm that their blend of precision engineering and customer care makes them a standout CNC Manufacturing Company. Their reputation for quality and reliability is well-earned, and their continued innovation ensures they remain a leader in the industry.

Innovations in CNC Machining

CNC Manufacturing has revolutionized the way industries like aerospace, automotive, and medical create intricate components with unmatched precision. At Anco Precision Inc., we take pride in pushing the boundaries of what CNC Manufacturing can accomplish. With over 40 years of experience, our family-owned business has witnessed the evolution from rudimentary controls to cutting-edge, fully automated systems that we champion today.

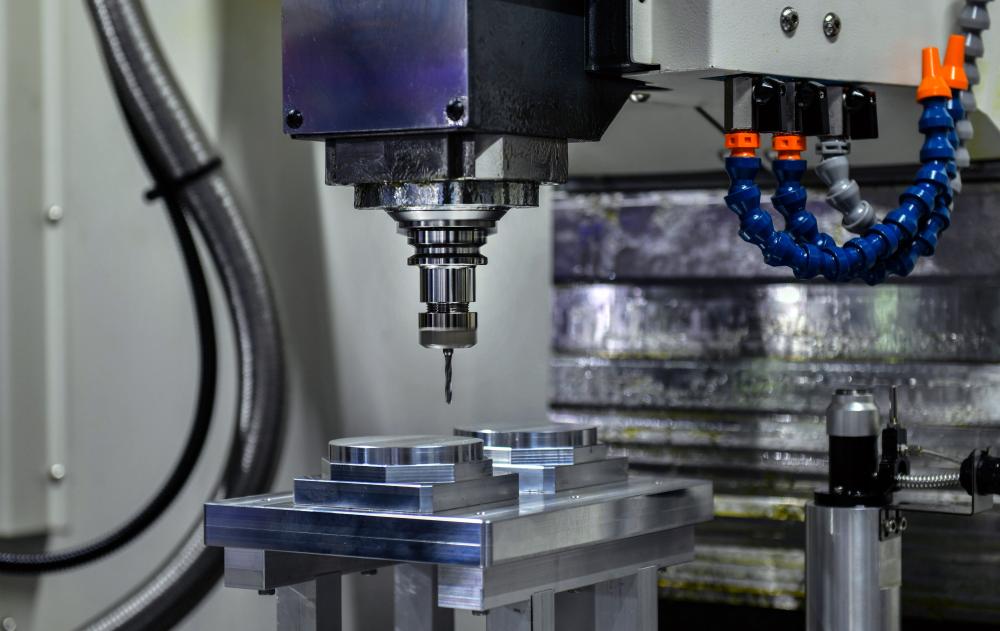

Our team has embraced the technological advancements that have transformed CNC Manufacturing into an art form. From state-of-the-art CNC mills and lathes to plasma and waterjet cutters, each machine is an essential tool in our workshop. These machines allow us to tackle diverse projects, from crafting custom car parts to producing precise medical instruments. Our commitment to staying at the forefront of technology ensures we can adapt to new challenges and satisfy a wide array of customer needs.

Precision and Quality in Every Project

Anyone familiar with CNC Manufacturing knows that precision is the cornerstone of success. At Anco Precision Inc., we’ve built our reputation on delivering products that meet stringent accuracy requirements. Our machinists undergo extensive training to operate the latest equipment, ensuring that each component is manufactured to exact specifications. This dedication to quality is why our clients trust us to produce parts for everything from optical devices to experimental prototypes.

It’s not just about the machines; it’s about the people behind them. Our skilled team collaborates closely with clients throughout the design and manufacturing process, ensuring every detail is captured. This interaction fosters a deep understanding of our clients’ goals and allows us to offer innovative solutions that may not have been initially considered. This commitment to collaboration is a key reason clients choose Anco Precision for their CNC Manufacturing needs repeatedly.

Industry Insights from a Legacy of Excellence

CNC Manufacturing is more than just a process–it’s a field that requires continuous learning and adaptation. Having worked with numerous industries, including government agencies and educational institutions, we’ve realized that the exchange of ideas keeps our operations dynamic and impactful. Each industry offers unique challenges that require custom solutions, and we’ve developed a reputation for overcoming these barriers with ingenuity and speed.

One particular project that stands out involved creating rapid prototypes for an aerospace client. They needed components that could withstand extreme conditions while maintaining strict weight limitations. Our team worked tirelessly to optimize the design and production processes, ensuring the final products not only met but exceeded the client’s expectations. This project highlights how CNC Manufacturing can be tailored to produce bespoke solutions that align with the specific demands of any industry.

We also recognize the importance of providing accessible and efficient services. Our online platform allows clients to submit designs and receive instant quotes, streamlining the early stages of any project. This feature underscores our commitment to convenience without compromising on the quality and precision that define CNC Manufacturing at Anco Precision Inc.

Diverse Industries Served by CNC Manufacturing Florida

CNC Manufacturing Florida is at the heart of innovation and precision, providing crucial services to many industries. Anco Precision Inc., a seasoned player in this space, has carved a niche by serving the marine, automotive, medical, and aerospace sectors. Each industry demands specific expertise, and Anco Precision’s 40 years of experience equip them well to meet and exceed these standards. Their commitment to precision ensures that every product, whether a custom car part or a medical instrument, is manufactured with exacting attention to detail.

In the world of CNC Manufacturing Florida, Anco Precision’s dedication to quality is unparalleled. The company’s machinists go through rigorous training, mastering state-of-the-art equipment to deliver exceptional products. With CNC milling, turning, and rapid prototyping in their arsenal, they cater to diverse manufacturing needs. Anco Precision’s ability to consistently deliver high-quality products at competitive prices makes them a trusted partner.

Anco Precision’s clientele includes government agencies, universities, and individual inventors, highlighting their versatility and broad appeal. By offering instant quotes through their online machine shop, they have revolutionized the way projects are initiated, making the process seamless and efficient for all stakeholders. This innovative approach positions them as leaders in CNC Manufacturing Florida.

Unmatched Precision and Technology in CNC Manufacturing Florida

State-of-the-Art Equipment

At the core of CNC Manufacturing Florida is the use of cutting-edge technology to achieve unmatched precision. Companies like Anco Precision have invested significantly in state-of-the-art CNC machinery to ensure that every product meets the highest standards. The combination of advanced equipment and highly skilled machinists allows for complex projects to be executed flawlessly, maintaining a high level of precision across the board.

Adaptability and Customization

One of the standout features of CNC Manufacturing Florida is its ability to adapt and customize solutions for various industries. Anco Precision excels in providing tailored solutions, whether it’s prototyping a new design or producing a large-scale production run. Their approach is rooted in collaboration with clients, ensuring that every project aligns with specific requirements, from custom enclosures to intricate mechanical components.

Customer Feedback

Testimonials from satisfied clients speak volumes about the quality and reliability of services in CNC Manufacturing Florida. Anco Precision’s customers frequently highlight their professionalism, quick turnaround times, and competitive pricing. This consistent feedback reinforces their reputation as leaders in the field, where attention to detail and customer satisfaction are paramount.

Efficiency and Timeliness

Time is often of the essence in CNC Manufacturing Florida, and Anco Precision understands this implicitly. Their efficient processes and quick delivery times ensure that projects meet deadlines without compromising on quality. This emphasis on efficiency is a key differentiator, allowing them to stand out in a competitive market and maintain strong relationships with their clients.

Personal Insights into CNC Manufacturing Florida

Working with Anco Precision, I’ve witnessed firsthand the company’s commitment to excellence in CNC Manufacturing Florida. Each project is an opportunity to learn and innovate, pushing the boundaries of what CNC technology can achieve. The team’s dedication to precision and quality is evident in every aspect of their work, from the initial consultation to the final product delivery.

The work environment fosters collaboration and continuous improvement, encouraging machinists to hone their skills and embrace new technologies. Anco Precision’s focus on customer satisfaction goes beyond just meeting deadlines; it’s about building lasting partnerships based on trust and mutual success. Their approach is both detailed and flexible, ensuring that each client’s unique needs are met with bespoke solutions.

Having collaborated with Anco Precision, the significance of CNC Manufacturing Florida in driving innovation and industrial growth becomes apparent. It’s a field marked by continuous evolution and the relentless pursuit of perfection, and companies like Anco Precision are at the forefront, setting new standards and expectations.

What makes precision so critical in CNC manufacturing, and how do companies like Anco Precision ensure it?

Precision is the cornerstone of CNC manufacturing because even the smallest deviation can result in a product that doesn’t meet the client’s requirements or safety standards. At Anco Precision, we ensure precision by investing in extensive training for our machinists and using state-of-the-art equipment. We meticulously craft each component, whether it’s a custom car part or a medical instrument, to exact specifications. This focus on precision not only satisfies our clients’ needs but also optimizes our manufacturing processes by reducing waste and increasing efficiency. Imagine creating a delicate aerospace component that has to fit perfectly; that’s where precision becomes non-negotiable. Have you ever considered how precision impacts the reliability of products you use daily?

How versatile is CNC manufacturing, and what industries benefit most from services like those offered by Anco Precision?

CNC manufacturing is incredibly versatile, accommodating a wide variety of industries. At Anco Precision, we serve sectors such as marine, automotive, aerospace, and medical, each with its unique set of needs. This versatility comes from our ability to handle different processes like CNC milling, turning, and rapid prototyping. For example, an aerospace company may require complex parts with tight tolerances, while a medical firm might need precise medical instruments. This adaptability has made us popular among diverse clients–from government agencies to individual inventors. Have you ever thought about the range of products around you that might have been made through CNC manufacturing?

What distinguishes advanced machining capabilities in a CNC manufacturing company?

Advanced machining capabilities are defined by the ability to handle both complex, one-off prototypes and high-volume production runs efficiently. At Anco Precision, our advanced capabilities allow us to offer instant quotes online, which streamlines the project initiation process for designers and developers. Using cutting-edge technology, we can provide detailed feedback on project feasibility and cost implications almost immediately. Our clients find this particularly useful when they need to quickly pivot or modify designs. Consider how digital tools have changed the way products are developed and brought to market–streamlining processes and encouraging innovation.

How does a customer-centric approach enhance the services of a CNC manufacturing company like Anco Precision?

At Anco Precision, our customer-centric approach is integral to our success. It involves understanding and adapting to client needs, providing personalized service, and maintaining open communication channels. Whether a client requires in-person consultations or prefers digital interactions, our focus is on delivering exceptional service. This approach ensures that we can cater to both large contracts and individual entrepreneurs effectively. By prioritizing customer satisfaction, we build lasting relationships and foster a sense of trust. Have you noticed how businesses that focus on customer needs often stand out in their industry?

What are the latest innovations in CNC machining, and how do they impact companies like Anco Precision?

Innovations in CNC machining have significantly transformed the industry, particularly in terms of automation and digital integration. At Anco Precision, we embrace cutting-edge technologies such as fully automated CNC mills, lathes, and digital quoting platforms. These innovations increase our capacity to deliver precise parts quickly and efficiently. Moreover, they enhance our ability to customize solutions for complex projects. Have you ever thought about how the integration of technology into traditional manufacturing processes is reshaping industries today?

Why is quality assurance crucial in CNC manufacturing, and how is it achieved?

Quality assurance guarantees that every product meets defined standards and specifications, which is crucial for maintaining reliability and safety. At Anco Precision, we achieve this through rigorous training of our machinists and by implementing thorough checks throughout the manufacturing process. Every component we produce is subject to continuous scrutiny to ensure it meets our high standards. This dedication to quality is why clients trust us with essential projects, from optical devices to critical aerospace parts. What measures do you think are essential for maintaining quality in manufacturing?

How is CNC Manufacturing significant in Florida, and what role does Anco Precision play in this context?

CNC Manufacturing is a key driver of Florida’s industrial capability, providing vital services to numerous sectors, including marine, aerospace, and medical. Anco Precision is a prominent player in this landscape, offering unmatched precision and technical expertise. Our commitment to serving diverse industries with tailored solutions positions us as a leader. From delivering custom car parts to precise medical instruments, our work supports various applications that are crucial to Florida’s economy. Do you know any local industries relying on CNC services, perhaps without realizing it?

What unique challenges do CNC manufacturing companies face, and how does Anco Precision address them?

Challenges in CNC manufacturing often include staying ahead with technology, meeting tight tolerances, and adapting to diverse client needs. At Anco Precision, we tackle these by continuously investing in advanced equipment and training. Our ability to adapt and customize our offerings ensures that we can meet specific requirements across industries. By collaborating with clients, we often uncover creative solutions to complex problems. Have you ever brainstormed innovative solutions for a challenge in your work or field?

Resources

- NASA – National Aeronautics and Space Administration – The official website of NASA, providing information on space exploration and aeronautics research.

- NIH – National Institutes of Health – The official website of the NIH, offering resources on medical research and healthcare advancements.

- NSF – National Science Foundation – The official website of the NSF, focusing on funding and supporting research in science and engineering.

- NIST – National Institute of Standards and Technology – The official website of NIST, providing standards and technology resources for various industries.

- CDC – Centers for Disease Control and Prevention – The official website of the CDC, offering information on public health and disease control.