Introduction

At Anco Precision Inc., we’ve spent over four decades honing our craft in the CNC machine shop industry, establishing ourselves as a cornerstone of precision and quality. Our journey has given us a unique perspective on manufacturing, especially when it comes to billet parts. In this article, we’ll dive deep into the world of billet parts, shedding light on their importance, manufacturing processes, and the unparalleled quality they bring to diverse industries.

Understanding Billet Parts

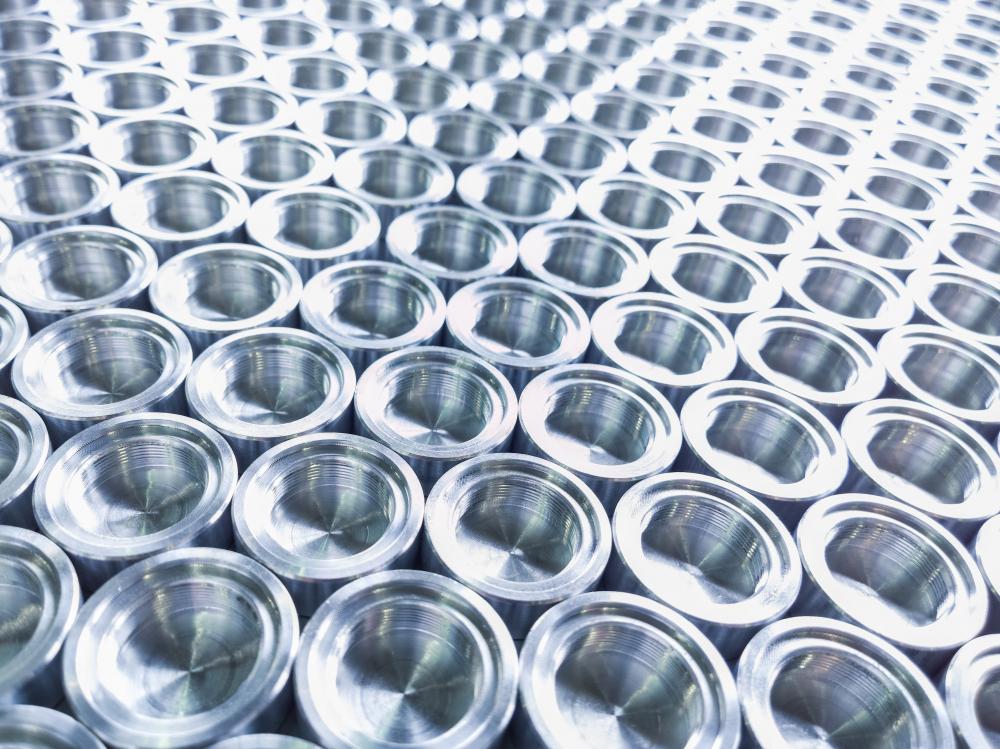

Before we delve into the intricacies, let’s establish what we mean by billet parts. These parts are crafted from a single block of material, usually metals like aluminum or steel, through a process of cutting and drilling using Computer Numerical Control (CNC) machinery. This method allows for intricate designs and precision that are often unachievable with traditional manufacturing processes.

Advantages of Billet Parts

One of the first things our clients notice about our billet parts is their exceptional strength and durability. Due to the continuous grain flow that remains intact during machining, billet parts boast enhanced structural integrity. This characteristic is crucial for applications where reliability under stress is paramount, such as in the aerospace and automotive industries.

The Manufacturing Process

Turning Ideas into Reality

At Anco Precision Inc., the process of creating billet parts begins with a concept. Our clients come to us with a vision, and our team of engineers uses CAD software to turn that vision into a detailed design. This is where our expertise truly shines, as we refine each design to maximize the part’s functionality and manufacturability.

CNC Machining Excellence

Once the design is finalized, it’s over to our state-of-the-art CNC machines, where the raw billet material is transformed into a precision part. Our machinists are artists in their own right, skilled in the nuances of CNC milling and turning to ensure every curve, angle, and dimension is as intended.

Materials in Focus

Not all materials are created equal, and in the world of billet parts, the choice of material is as critical as the design itself. Aluminium, known for its lightweight and strength, is a popular choice, especially 6061 and 7075 alloys. Each material we select for our billet parts is chosen for its ability to meet the specific demands of the part’s application, whether it be corrosion resistance, strength-to-weight ratio, or thermal conductivity.

Applications of Billet Parts

The versatility of billet parts allows them to be used across a vast array of industries. From custom automotive components that demand both aesthetics and performance to aerospace parts that must withstand extreme conditions, the applications are as varied as they are critical. In the medical field, the precision of billet parts makes them ideal for intricate devices, while in marine applications, their corrosion resistance and strength are highly valued.

Why Choose Anco Precision Inc.?

A Tradition of Excellence

Our commitment to quality is not just a slogan but a promise we’ve kept for over 40 years. At Anco Precision Inc., we understand that each billet part we produce plays a vital role in our clients’ projects and industries. That’s why we approach each project with a blend of technical expertise and creative problem-solving.

State-of-the-Art Technology

Our facility is equipped with the latest in CNC machining technology, allowing us to produce billet parts with unparalleled precision. This technological edge, combined with our skilled team, means we can tackle projects of any complexity.

Partnership and Collaboration

We see ourselves as more than just a supplier; we are a partner in our clients’ success. Our team works closely with each client, offering insights, suggestions, and support throughout the manufacturing process to ensure the final product exceeds expectations.

Getting Started

Embarking on a manufacturing project can seem daunting, but with Anco Precision Inc., it’s a streamlined and collaborative process. Our instant quote system allows for a seamless start, ensuring your project kicks off without delay. By submitting a drawing file through our online platform, clients can quickly receive a detailed quote, marking the first step towards bringing their vision to life.

Conclusion

At Anco Precision Inc., we’ve built our reputation on delivering exceptional billet parts to a wide range of industries. Our dedication to precision, quality, and customer satisfaction sets us apart, making us a trusted partner in the machining industry. Whether it’s for aerospace, automotive, medical, or any other field, our team is ready to bring your project to fruition with the precision and care it deserves.

What is a billet part?

You know, when we talk about billet parts at Anco Precision Inc., we’re diving into the world of craftsmanship and precision. These parts are essentially born from a single block of material–usually metals like aluminum or steel. Imagine taking a solid rectangle of metal and then, using our advanced Computer Numerical Control (CNC) machinery, we meticulously carve it down to the specified design. This process allows us not only to achieve intricate designs but also to maintain the strength of the material by preserving its natural grain structure. It’s like sculpting with metal, where each piece becomes a testament to both our technology and our expertise.

Why are billet parts so expensive?

Ah, we hear this question a lot, and understandably so. Crafting billet parts isn’t just about cutting metal; it’s about precision and customization. The process involves using high-grade material–a block of aluminum or steel, for instance–and then, each part is individually machined using CNC machinery. This machinery isn’t your everyday hardware; it’s state-of-the-art technology that requires skilled operators. So, when you’re paying for a billet part, you’re paying for the material, the time, and the expertise that goes into it. It’s an investment in durability, precision, and aesthetic appeal that off-the-shelf components simply can’t match. Think of it as buying a tailored suit versus an off-the-rack one; both serve the same purpose, but the former fits you like a glove and lasts significantly longer.

What does billet mean in automotive?

In the automotive world, “billet” speaks to the heart of customization and performance. When we use billet parts in automotive applications, we’re talking about components that have been custom-machined from solid blocks of material. These aren’t mass-produced parts; they’re designed to meet specific performance criteria, whether that’s reducing weight, increasing strength, or simply adding that unique aesthetic touch to a vehicle. Automotive enthusiasts and professionals choose billet parts for their superior integrity and the ability to withstand the rigorous demands of racing and high-performance applications. It’s about pushing the envelope of what’s possible, one precisely machined part at a time.

What is the difference between billet and aluminum?

Now, this is a common point of confusion. Let’s clarify: Aluminum is a material, while “billet” refers to how the material is processed. You can have billet aluminum, which means the aluminum has been machined from a solid block, as opposed to being cast or extruded. What sets billet aluminum apart is the controlled process of cutting it from a single piece, which maintains the material’s strength and grain structure. The beauty of billet parts, especially when made from aluminum, is that they offer a fantastic balance of lightweight and strength, making them ideal for many applications from automotive to aerospace. It’s a fine distinction, but understanding it helps appreciate why billet aluminum stands out in terms of quality and performance.

How does the choice of material affect the quality of billet parts?

Choosing the right material for billet parts is akin to selecting the perfect ingredient for a gourmet recipe. Each material brings its unique properties to the table. For instance, aluminum alloys like 6061 and 7075 are favored for their fantastic strength-to-weight ratio, making them perfect for high-performance applications. On the other hand, steel, being denser and more durable, is chosen for components that require extreme resilience. At Anco Precision Inc., we consider factors like the intended application, environmental conditions, and stress factors before selecting a material. It’s a critical decision that affects everything from manufacturability to the final part’s performance in the field.

What sets Anco Precision Inc. apart in the production of billet parts?

Well, it’s our dedication to precision, quality, and collaboration that truly sets us apart. We’ve been in this business for over 40 years, and in that time, we’ve honed our skills to near perfection. Our approach is not just about making parts–it’s about understanding our clients’ needs and exceeding their expectations. We leverage state-of-the-art CNC machinery, yes, but it’s our team’s expertise and our collaborative approach to projects that make the difference. We’re not just a supplier; we’re a partner in our clients’ success, offering insights, suggestions, and support throughout the manufacturing process. It’s this tradition of excellence and commitment to customer satisfaction that makes Anco Precision Inc. a trusted partner in the machining industry.

Resources

- National Institute of Standards and Technology (NIST) – Visit the NIST website to access valuable resources on manufacturing standards and technology.

- NASA – Explore NASA’s website to learn more about aerospace applications of billet parts and advanced manufacturing processes.

- American Academy of Orthopaedic Surgeons (AAOS) – Discover how billet parts are used in medical applications by visiting the AAOS website.